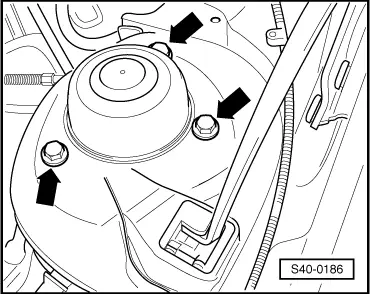

| Suspension strut to suspension strut dome | 15 Nm + 90° |

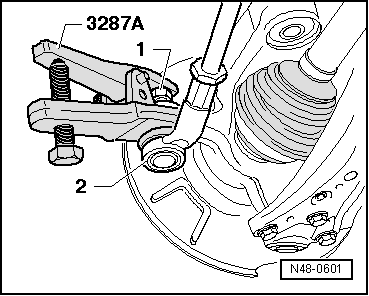

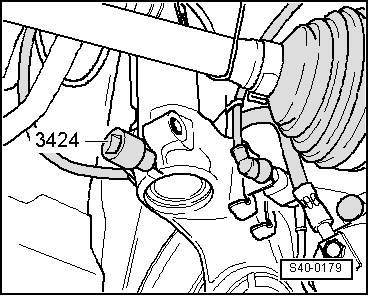

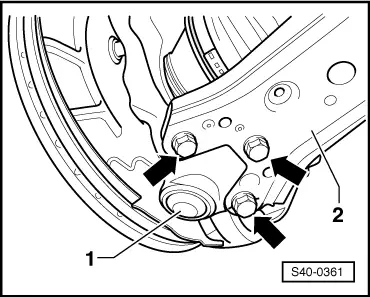

Wheel-bearing housing to suspension strut| t

| Use new screws and nuts! |

| 60 Nm + 90° |

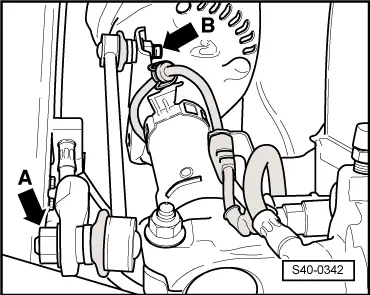

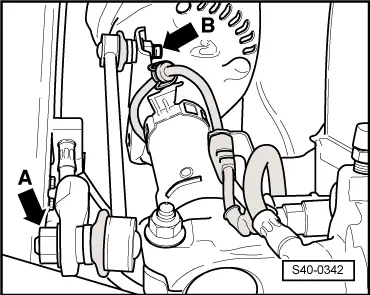

| Track rod end/track rod to steering arm | 20 Nm + 90° |

| The anti-roll bar on the suspension strut | 40 Nm |

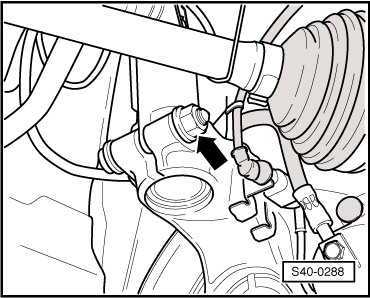

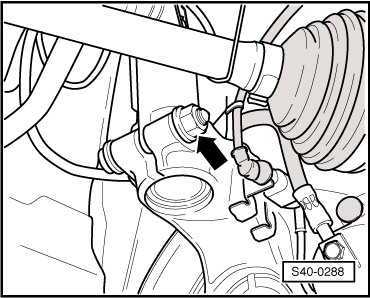

Twelve-point nut for securing the drive shaft to wheel hub with mechanical steering| t

| Do not grease thread of the outer joint of the drive shaft. |

| 50 Nm |

Twelve-point nut for securing the drive shaft to wheel hub with power-assisted steering| t

| Do not grease thread of the outer joint of the drive shaft. |

| 50 Nm + 45° |

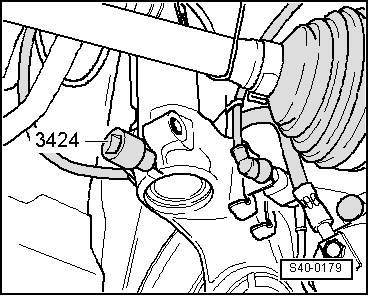

| Steering joint to track control arm | 20 Nm + 90° |

| Wheel bolts | 120 Nm |

Note

Note

Caution

Caution