Fabia Mk1

|

|

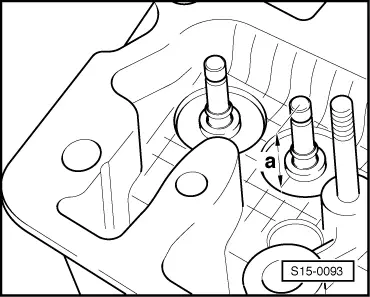

| Maximum dimensions in mm | 1.0 ltr. engine | 1.4 ltr. engine |

| Inlet valve | 43,1 | 42,7 |

| Exhaust valve | 43,0 | 42,8 |

|

| Maximum dimension | 43,1 | mm | |

| - | Measured distance | 42,7 | mm |

| = | max. permissible reworking dimension | 0,4 | mm |

Note

Note

|

|

|

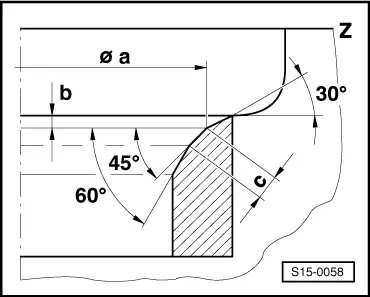

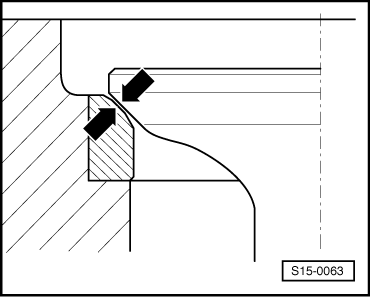

| Dimension | Valve seats | ||

| 1.0 ltr. engine: | |||

| Ø a | mm | Valve seat diameter: | 33,4 ± 0.1 - inlet valve 26.4 ± 0.1 - exhaust valve |

| 1.4 ltr. engine: | |||

| Ø a | mm | Valve seat diameter: | 32.9 -0.1 - inlet valve 29.6 -0.1 - exhaust valve |

| b | mm | max. permissible reworking dimension | |

| 1.0 ltr. engine: | |||

| c | mm | Valve seat width: | 1.3 up to 1.6 - inlet and exhaust valve |

| 1.4 ltr. engine: | |||

| c | mm | Valve seat width: | 1,45 up to 1,75 - inlet valve 1,65 up to 1,95 - exhaust valve |

| Z | Bottom edge of cylinder head | ||

| 45° | Valve seat angle | ||

| 30° | Top correction angle | ||

| 60° | Bottom correction angle | ||

|

|

|

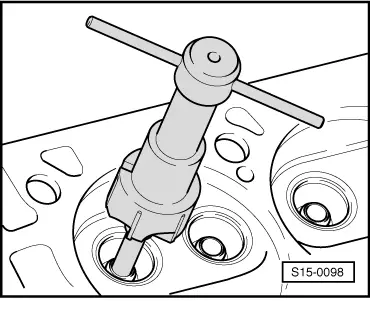

| Valve guide | Ø Guide drift in mm |

| Inlet valve | 7,0 -0,01 |

| Exhaust valve |

|

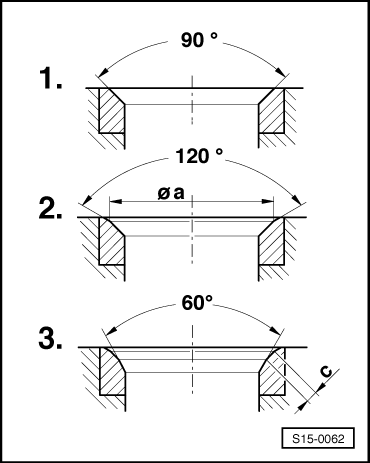

| Valve seat | Ø Milling cutter 90 mm | Ø Milling cutter 120 mm | Ø Milling cutter 60 mm | |

| Inlet valve | 1.0 ltr. engine | 36 | 38 | 21/34 |

| 1.4 ltr. engine | 36 | 38 | 21/34 | |

| Exhaust valve | 1.0 ltr. engine | 30 | 30 | max. 30 → Note |

| 1.4 ltr. engine | 32 | 32 | 21/34 | |

|

|

|

Note

Note

|

|