Octavia Mk1

Note

Note

|

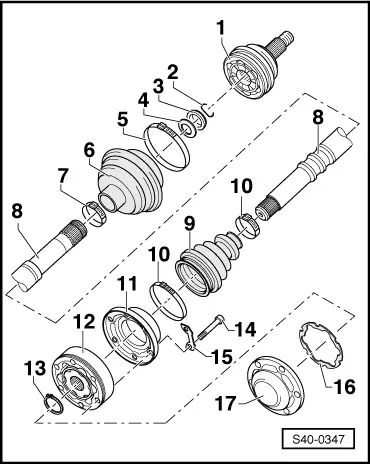

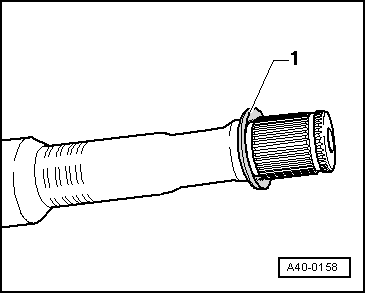

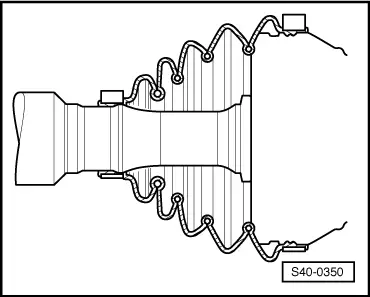

| 1 - | Outer CV joint |

| t | must be replaced completely |

| t | removing → Fig. |

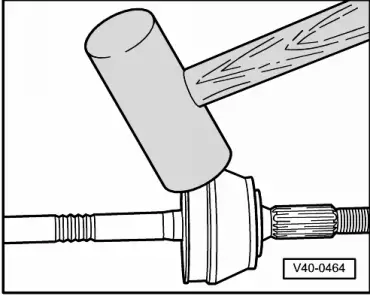

| t | install: drive onto the shaft with a plastic hammer until the compressed circlip expands |

| t | grease → Anchor |

| t | check → Chapter |

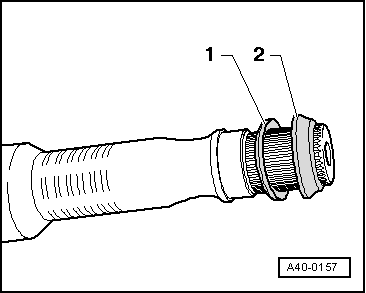

| 2 - | Circlip |

| t | replace |

| t | insert into the groove at the shaft |

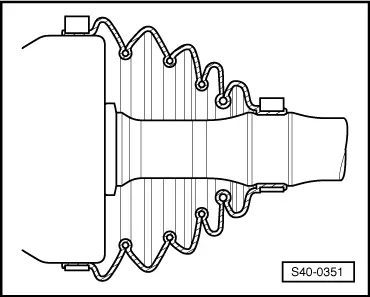

| 3 - | Thrust ring |

| t | Fitting position → Fig. |

| 4 - | Disc spring |

| t | Fitting position → Fig. |

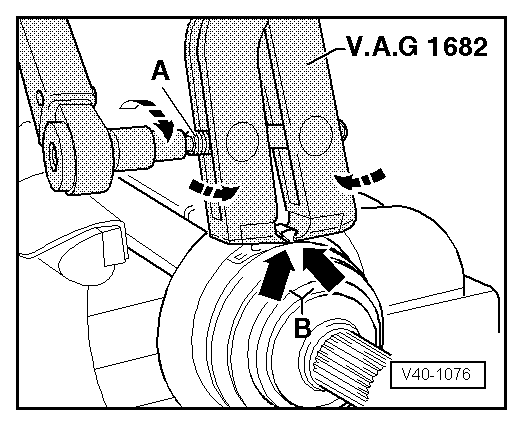

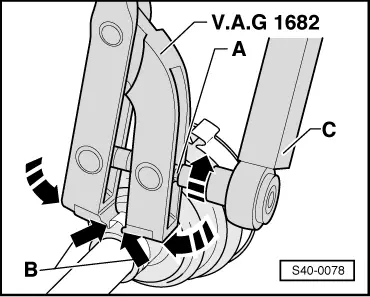

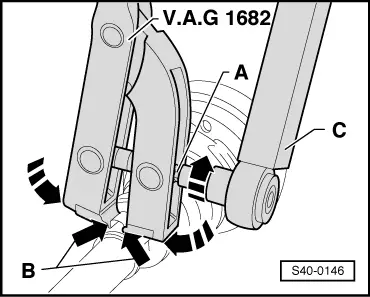

| 5 - | Open warm-type clamp |

| t | replace |

| t | tension with tensioning pliers, e.g. -V.A.G 1682-, → Fig. |

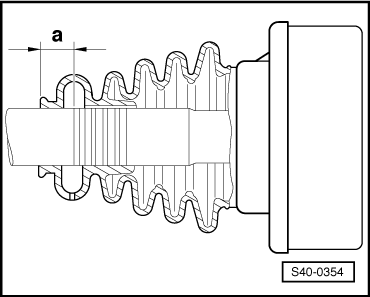

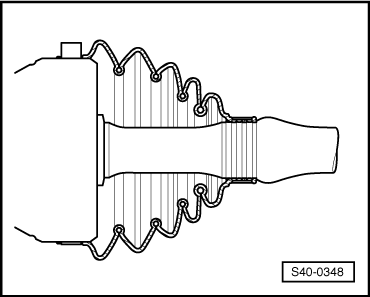

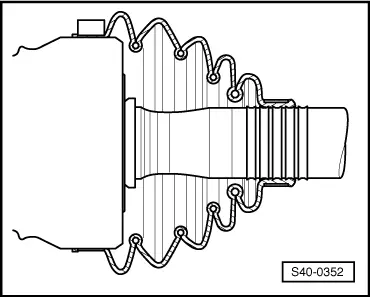

| 6 - | Joint boot for outer CV joint |

| t | Material: Hytrel (Polyelastomere) |

| t | inspect for tears and chafing points |

| t | Fitting position for the left shaft → Fig. |

| t | Fitting position for the right shaft → Fig. |

| t | Assignment → Electronic Catalogue of Original Parts |

| 7 - | Open warm-type clamp |

| t | replace |

| t | tensioning → Fig. |

| 8 - | Drive shaft |

| t | Assignment → Electronic Catalogue of Original Parts |

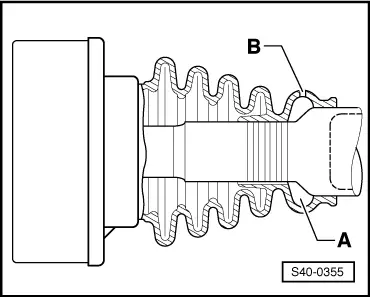

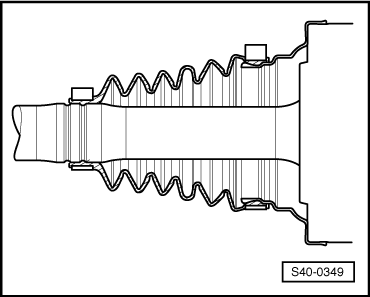

| 9 - | Joint boot for inner CV joint |

| t | Material: Arnitel (Polyelastomere) |

| t | inspect for tears and chafing points |

| t | Fitting position for the left shaft → Fig. |

| t | Fitting position for the right shaft → Fig. |

| t | Assignment → Electronic Catalogue of Original Parts |

| 10 - | Open warm-type clamp |

| t | replace |

| 11 - | Cover |

| t | remove from CV joint with drift |

| t | before installation coat the sealing surface of the cap with sealant -D 454 300 A2- |

| t | The sealing surface must be free of oil and grease! |

| 12 - | Inner CV joint |

| t | must be replaced completely |

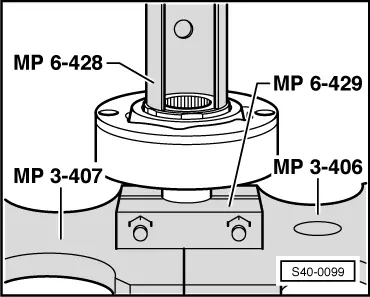

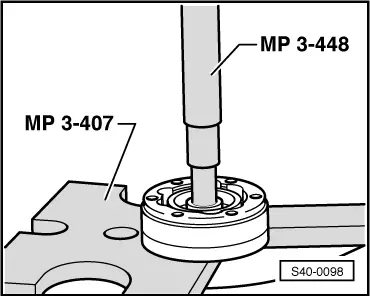

| t | pressing out → Fig. |

| t | pressing on → Fig. |

| t | grease → Anchor |

| t | check → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| 13 - | Circlip |

| t | replace |

| t | remove with circlip pliers, e.g. -VW 161A-, |

| 14 - | Fillister head screw with internal serrations |

| t | replace after each removal |

| t | initially tighten to 10 Nm, subsequently tighten crosswise to final torque: |

| M8 x 48 = 20 Nm + 180° |

| M10 x 52 = 50 Nm + 45° |

| t | Assignment → Electronic Catalogue of Original Parts |

| 15 - | Shim |

| t | Assignment → Electronic Catalogue of Original Parts |

| 16 - | Gasket |

| t | The adherend on the inner CV joint must be free of grease and oil! |

| t | replace |

| t | Remove the protective foil from the gasket and stick it into the inner joint |

| t | Assignment → Electronic Catalogue of Original Parts |

| 17 - | Cover |

| t | remove from CV joint with drift |

| t | before installation coat the sealing surface of the cap with sealant -D 454 300 A2- |

| t | The sealing surface must be free of oil and grease! |

Note

Note

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|