| –

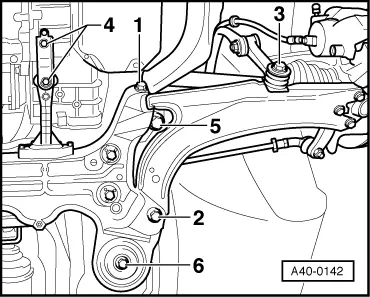

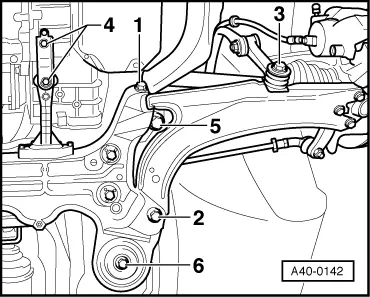

| Unscrew screws -3-, if present, at the track control arm. |

| –

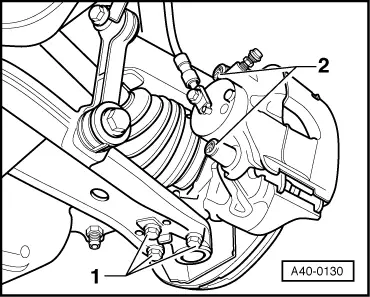

| Screw out screws -1- and -2-. |

| –

| Remove the track control arm. |

| Only for vehicles with autom. gearbox |

| –

| Release screws -4- for pendulum support. |

| –

| Unscrew screws -5- and -6- for assembly carrier. |

Note | Release the screw -1- downwards by slightly pressing the assembly carrier and take out the wheel-bearing housing. |

| (Valid for vehicles with manual and automatic gearbox). |

| Remove possible corrosion in the thread/serration of the outer joint. |

| –

| Insert track control arm and secure. |

| –

| Secure assembly carrier. |

| –

| Moisten the serration of the wheel hub with oil. |

| –

| Insert outer joint as far as possible into the serration of the wheel hub. |

| –

| Screw the steering joint and track control arm with the new screws in the former positions. |

| –

| Screw the pendulum support to the gearbox. |

| –

| If necessary, screw the coupling rod with the track control arm or with the suspension strut. |

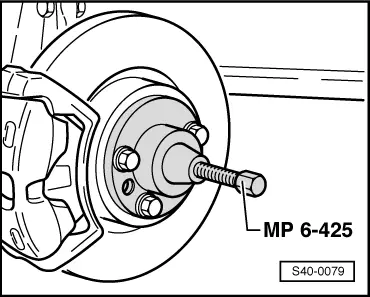

| – Moisten the contact surface of the twelve-point nut as well as the serration and the thread of the outer joint with oil and screw on new twelve-point nut as far as possible. |

| –

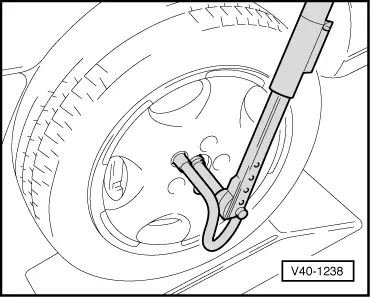

| Insert the outer joint into the wheel hub until the outer joint rests in the wheel bearing. |

| –

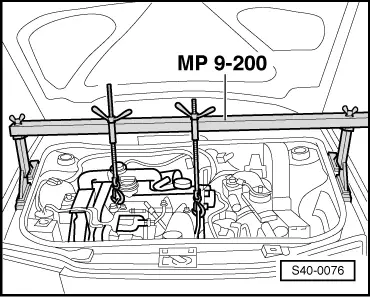

| Lower vehicle, when doing so, ensure that the wheels do not yet touch the ground. |

| If the wheel bearings are loaded through the vehicle's own weight, the wheel bearing will be initially damaged. This shortens the life of the wheel bearing. |

| –

| Depress brake pedal (assistance of second mechanic required). |

| –

| Tighten new twelve-point nut to 225 Nm and release by 1/2 a turn. |

| –

| Torque wheel hub a further min. 90°. |

| –

| Tighten twelve-point nut: |

Note |

|

|

Note

Note

Note

Note

Note

Note Note

Note