| –

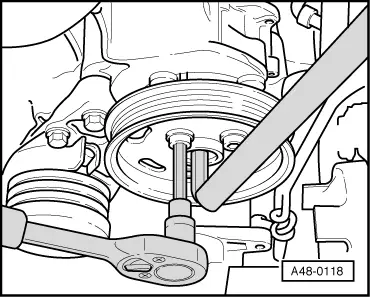

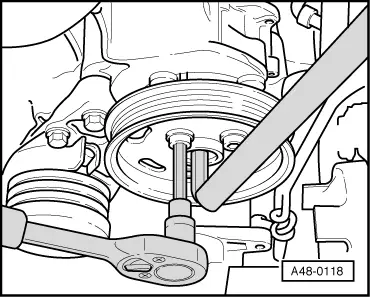

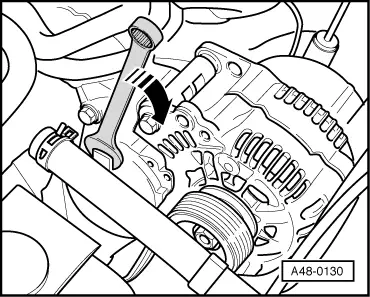

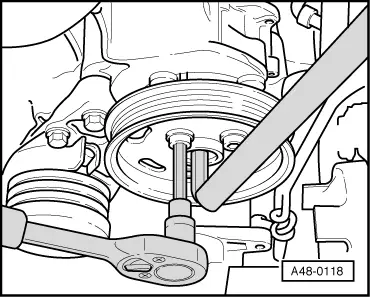

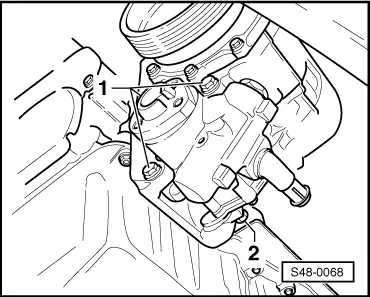

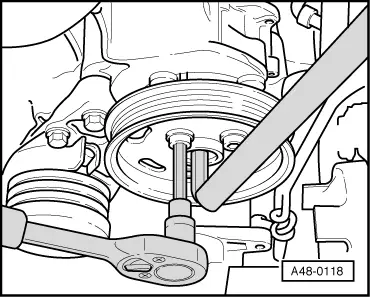

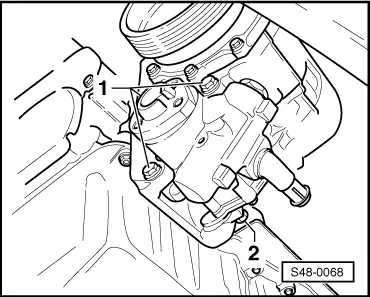

| Screw the belt pulley to the vane pump with Allan screws according to the made marking, counterhold with Allan key (SW 9 mm). |

Note | If the belt pulley of the vane pump is installed the wrong way round, it is displaced in relation to the other belt pulleys. The V-ribbed belt is damaged as a result of this displacement. |

| Continued for all vehicles |

| –

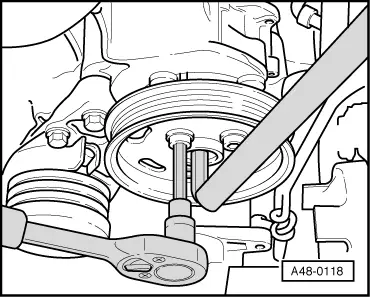

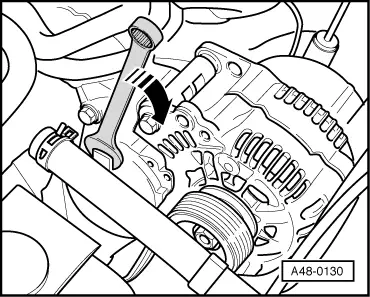

| Screw the belt pulley to the vane pump with Allan screws, counterhold with Allan key (SW 9 mm). |

Note | t

| Pay attention to the correct position of the V-ribbed belt in the belt pulley when installing it. |

| t

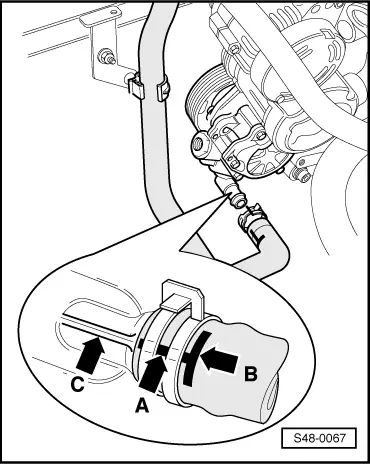

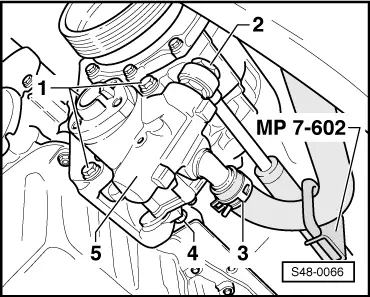

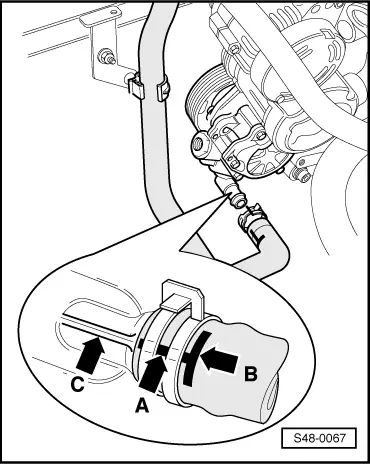

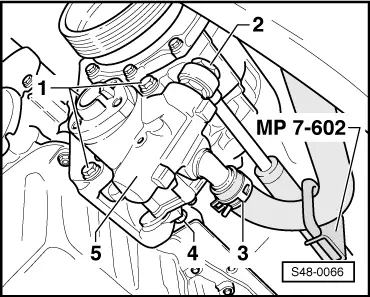

| Use new gasket rings to connect the pressure line. |

| –

| Install pressure line (expansion hose). |

| Tightening torque of the hollow screw or the pressure switch: 38 Nm |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note