Octavia Mk1

| Adjusting 2nd and 4th gear-brake -B2- on gearboxes with wave spring washer on the last outer plate |

| This setting instruction only applies to gearboxes with a wave spring washer Pos. 11 on the last outer plate Pos. 10 installed in the brake -B2-. |

Note

Note| t | On these gearboxes, the clearance of the brake -B2- is determined by the thickness of the adjusting washer(s). |

| t | Install components for adjustment without wave spring washer Pos. 11, without last outer plate Pos. 10 and without helical springs Pos. 6. |

| 1 - | Gearbox housing |

| 2 - | Circlip |

| q | for support pipe |

| 3 - | Support pipe -B2- |

| q | for the plate package of -B2- |

| q | different lengths, depending on the number of installed inner plates |

| q | assigned to gearbox identification characters as a spare part |

| q | insert in such a way that the groove grips into the wedge of the free wheel |

| 4 - | Outer plate -B2- |

| q | 3 mm thick |

| 5 - | Helical spring |

| q | install after installing the first outer plate Pos. 4 |

| 6 - | Helical spring |

| q | to adjust the -B2-- do not install |

| q | install before installing the last outer plate |

| 7 - | Spring |

| q | assigned to gearbox identification characters as a spare part |

| 8 - | Inner plate -B2- |

| q | Piece number → Chapter |

| q | assigned to gearbox identification characters as a spare part |

| 9 - | Outer plate -B2- |

| q | always install 2 mm thick outer plates |

| q | Piece number → Chapter |

| 10 - | Outer plate -B2- |

| q | do not install to adjust the -B2- |

| q | 2 outer plates can be installed for the adjustment. |

| 11 - | Wave spring washer |

| q | do not install to adjust the -B2- |

|

Note

Note

|

|

|

|

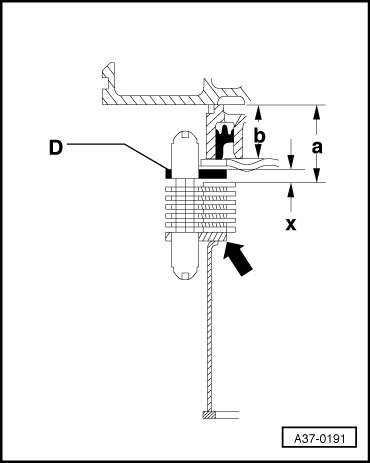

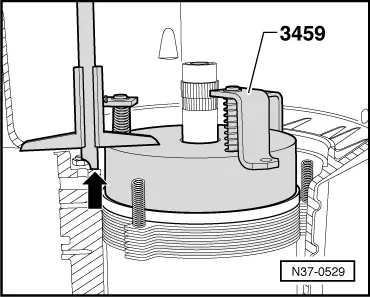

| Height of the adjusting device -3459- | = | 60.0 mm |

| - measured value | = | - 29.8 mm |

| determined value a | = | 30.2 mm |

|

|

|

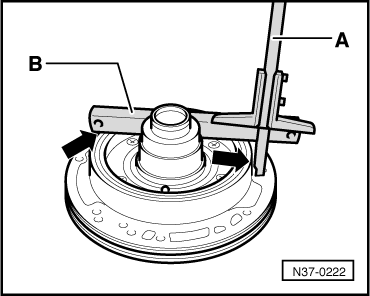

| measured value | = | 40.1 mm |

| - Straightedge | = | - 19.5 mm |

| determined value b | = | 20.6 mm |

|

| Gap size “x” (mm) | Plate (mm) |

| 4,25 … 4,49 4,50 … 4,74 4,75 … 4,99 | 2,75 3,00 3,25 |

| 5,00 … 5,24 5,25 … 5,49 5,50 … 5,74 | 3,50 3,75 2,00 + 2,00 |

| 5,75 … 5,99 6,00 … 6,24 6,25 … 6,49 | 2,00 + 2,25 2,25 + 2,25 2,25 + 2,50 |

| 6,50 … 6,74 6,75 … 7,00 | 2,50 + 2,50 2,50 + 2,75 |

|