Octavia Mk1

Note

Note

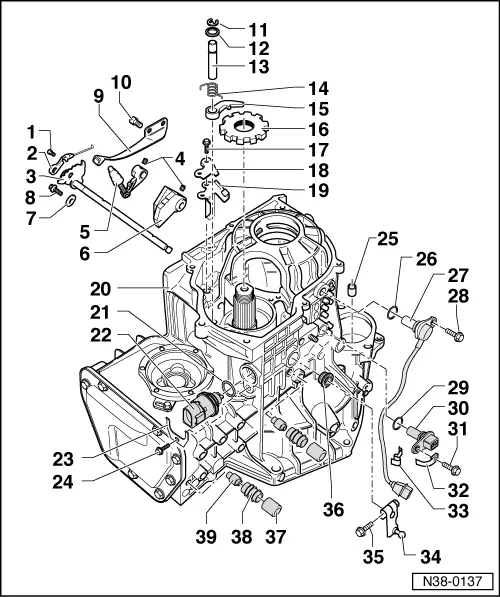

|

| 1 - | 4 Nm |

| q | for manuel slider lever |

| q | always replace → Electronic Catalogue of Original Parts |

| q | Replace steel spring and screw for actuation of manuel slider → Chapter |

| 2 - | Actuation of manuel slider |

| q | adjust → Chapter |

| q | Replace steel spring and screw for actuation of manuel slider → Chapter |

| 3 - | Gearshift shaft with shift segment |

| q | removing and installing → Fig. |

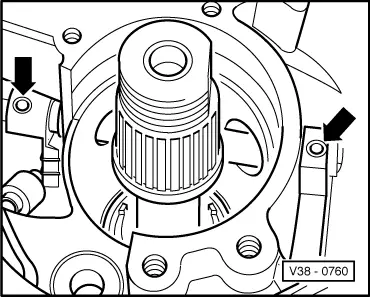

| 4 - | Tensioning sleeve |

| q | extracting and inserting → Fig. |

| 5 - | Engaging lever |

| q | insert together with gearshift shaft and detent segment |

| 6 - | Detent segment |

| q | insert together with gearshift shaft and engaging lever |

| 7 - | Lock washer |

| q | secures the shift shaft against wandering → Fig. |

| 8 - | 10 Nm |

| 9 - | Spring for shift segment |

| 10 - | 10 Nm |

| 11 - | Circlip |

| q | always replace → Electronic Catalogue of Original Parts |

| q | only install at axle with groove for securing ring |

| 12 - | Washer |

| 13 - | Axle for locking lever |

| q | is secured with the securing ring and the bearing cap of the input shaft |

| 14 - | Retracting spring |

| q | inserting → Fig. |

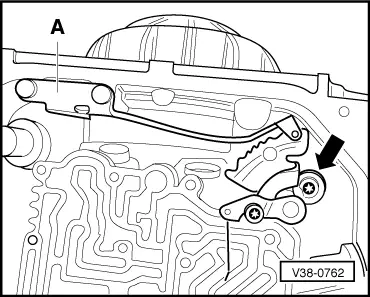

| 15 - | Locking lever |

| q | insert with retracting spring → Fig. |

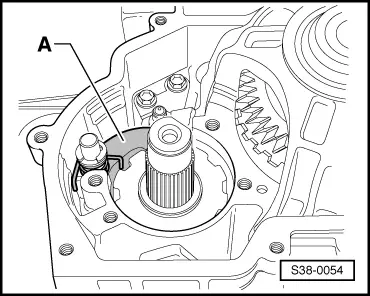

| 16 - | Parking position gear |

| q | the rounded side points to the serration of the input shaft |

| 17 - | 14 Nm |

| 18 - | Support plate |

| q | installing → Fig. |

| 19 - | Guide plate |

| q | insert in front of the support plate Pos. 18 → Fig. |

| 20 - | Gearbox housing |

| q | the drive gear must not be removed to disassemble the parking lock |

| 21 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

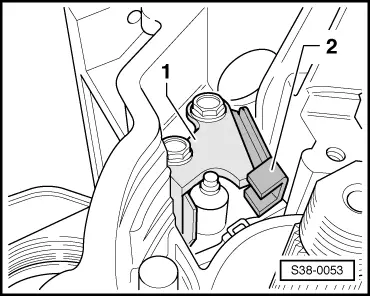

| 22 - | Multi-function switch -F125- |

| q | is checked by self-diagnosis → Chapter |

| q | remove before disassembling the shift shaft Pos. 3 |

| q | removing and installing → Fig. |

| 23 - | Support |

| q | for multi-function switch |

| 24 - | 10 Nm |

| 25 - | Bushing for starter |

| q | removing → Fig. |

| q | inserting → Fig. |

| 26 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

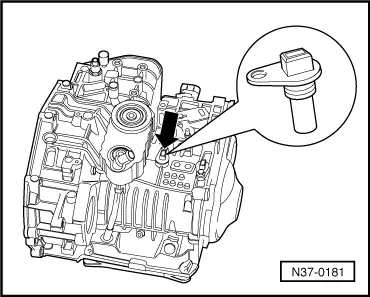

| 27 - | Vehicle speed sender -G68- |

| q | is checked by self-diagnosis → Chapter |

| q | adhering dirt impairs the operation, clean if necessary |

| q | removing and installing → Chapter |

| 28 - | 10 Nm |

| 29 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 30 - | Gearbox speed sender -G38- |

| q | is checked by self-diagnosis → Chapter |

| q | adhering dirt impairs the operation, clean if necessary |

| q | removing and installing → Fig. |

| 31 - | 10 Nm |

| 32 - | Retaining clip |

| q | for cable to vehicle speed sender -G68- |

| q | fasten with screw Pos. 31 |

| 33 - | Retaining clip |

| q | for cable of vehicle speed sender -G68- |

| q | press onto gearbox reinforcing rib |

| 34 - | Lever |

| q | for gearshift shaft |

| 35 - | 10 Nm |

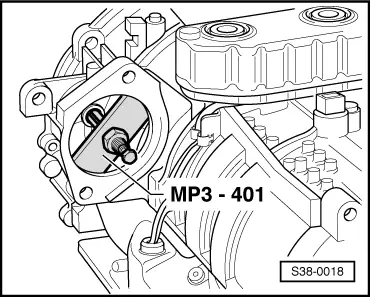

| 36 - | Gasket ring |

| q | release with a screwdriver |

| q | drive in using a pipe section -MP3-479 (VW 423)- until flush |

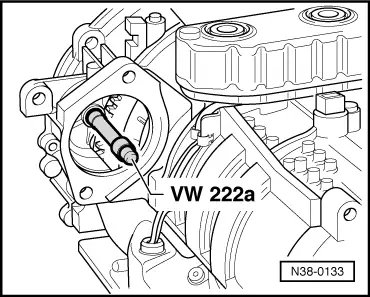

| 37 - | Ventilation cap |

| 38 - | Bleeding (of air) |

| 39 - | Ventilation tube |

| q | remove with pliers |

| q | drive in up to the stop with the drift -MP3-481/2 (VW 460/2)- |

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

WARNING

WARNING