| –

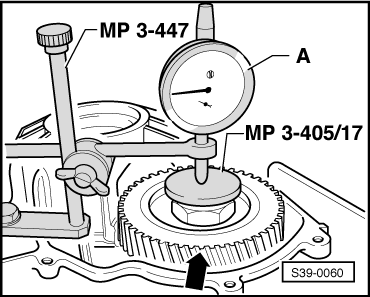

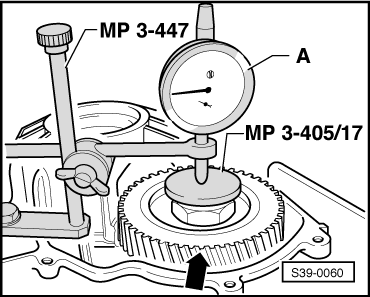

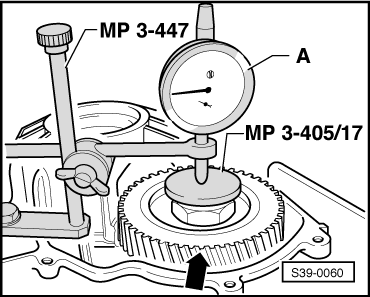

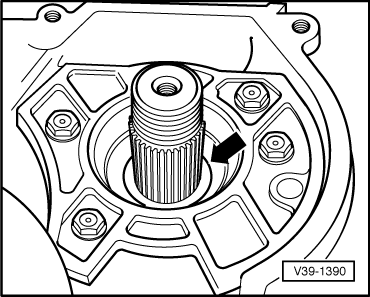

| Insert dial gauge -A- and set to “0” with a 1 mm bias. Move input shaft up and down. Read off play on dial gauge and note (example: 0.93 mm). |

Note | Do not turn the input shaft while measuring as otherwise the bearings will settle and the measuring result will be inaccurate. |

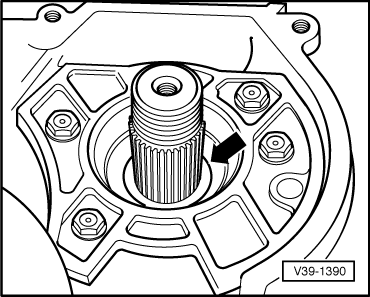

| Determine the adjusting washers |

| The determined bearing preload is reached by deducting the measured value of (0.93 mm) from the 2 x 1.5 mm thickness of the adjusting washers, 0.12 mm from the bearing preload and 0.10 mm from the setting amount. |

|

|

|

Note

Note

Note

Note