Octavia Mk1

|

|

|

|

|

|

|

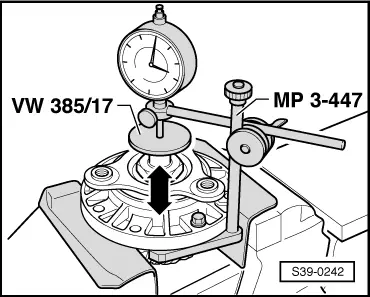

| Adjusting washer | 2.50 mm | |

| - | Compression (constant value) | 0.20 mm |

| - | Play (read off the dial gauge) | 0.35 mm |

| Adjusting washer S4= | 1.95 mm | |

Note

Note

|

| Adjusting washer thickness (mm) | |||

| 1,30 | 1,65 | 2,00 | 2,35 |

| 1,35 | 1,70 | 2,05 | 2,40 |

| 1,40 | 1,75 | 2,10 | 2,45 |

| 1,45 | 1,80 | 2,15 | 2,50 |

| 1,50 | 1,85 | 2,20 | |

| 1,55 | 1,90 | 2,25 | |

| 1,60 | 1,95 | 2,30 | |

Note

Note

|

|

|

|

|

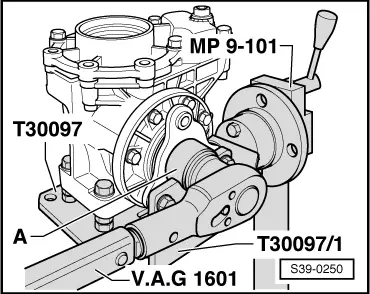

| new bearings | used bearings → Note |

| 100…240 Ncm | 30…50 Ncm |

|