Octavia Mk2

| Summary of components of lubrication system |

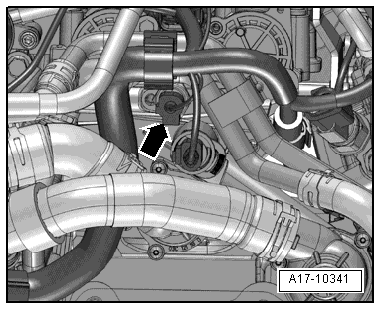

| Fitting location of the oil pressure switch -F1- and tightening torque → Fig. |

| 1 - | Dipstick |

| q | oil level must not exceed max. marking! |

| 2 - | Engine oil cooler |

| q | removing and installing → Chapter |

| 3 - | O-ring |

| q | replace |

| 4 - | Coolant pipe |

| q | for engine oil cooler |

| q | Tightening torque bracket to the cylinder block: 20 Nm |

| 5 - | 8 Nm |

| 6 - | Screw cap |

| q | Replace seal if damaged |

| 7 - | Sealing ring |

| q | replace if damaged |

| 8 - | Oil filter, 20 Nm |

| q | with gasket rings |

| q | with non-return valve |

| q | slacken and tighten with oil filter wrench -3417- |

| q | Keep to change intervals → Octavia II |

| 9 - | Timing case |

| q | Removing and installing the timing case → Chapter |

| 10 - | 10 Nm |

| 11 - | 150 Nm + torque a further 180° (1/2 turn) |

| q | replace |

| q | removing and installing → Chapter „Removing and installing crankshaft-belt pulley“ |

| q | The clamping surface of the fixing screw must be free of grease and oil. |

| q | insert oiled (thread) |

| q | Secure belt pulley with counterholder -T30004 (3415)- to prevent it from turning |

| 12 - | Belt pulley |

| q | removing and installing → Chapter |

| q | Clamping surfaces must be free of oil and grease. |

| q | Secure belt pulley with counterholder -T30004 (3415)- to prevent it from turning |

| q | Removing and installing ribbed V-belt → Chapter |

| 13 - | Sealing ring |

| q | replace |

| 14 - | Bushing |

| q | The clamping surfaces of the bushing must be free of grease and oil. |

| 15 - | Gasket |

| q | replace if damaged |

| 16 - | Sprocket |

| q | removing and installing → Chapter |

| q | for oil pump drive |

| 17 - | 20 Nm + torque a further 1/4 turn (90°) |

| q | replace |

| 18 - | Sprocket |

| q | removing and installing → Chapter |

| q | for oil pump |

| q | counterhold with counterholder -T10172- |

| 19 - | Drive chain |

| q | removing and installing → Chapter |

| q | for oil pump |

| q | mark running direction (installed position) before removing |

| 20 - | 10 Nm |

| 21 - | Oil level and oil temperature sender -G266 - |

| q | replace if damaged |

| q | check: → Current flow diagrams and Fitting locations |

| 22 - | Oil drain plug, 30 Nm |

| q | with captive seal |

| q | replace |

| 23 - | 13 Nm |

| q | replace |

| q | slacken and tighten only the bolts at the gearbox side with socket insert -T10058- |

| 24 - | 40 Nm |

| 25 - | Oil pan |

| q | removing and installing → Chapter |

| 26 - | 25 Nm |

| 27 - | Oil pump |

| q | must be replaced completely |

| 28 - | 5 Nm |

| 29 - | Oil separator |