Octavia Mk2

| Piston and conrod - Summary of components |

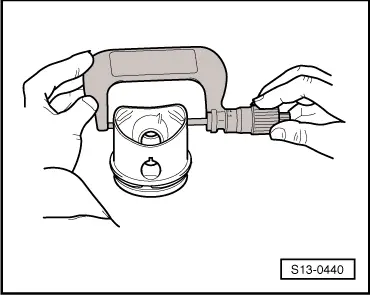

| 1 - | Piston |

| q | check → Fig. |

| q | mark installation position and matching cylinder |

| q | arrow on piston crown faces towards the belt pulley side |

| q | Piston Ø: 76.455 mm (nominal dimension) |

| 2 - | Piston pin |

| q | if stiff, heat piston to approx. 60°C |

| q | use drift -T10046- for removing and installing |

| 3 - | Circlip |

| 4 - | Conrod |

| q | always replace as a set only |

| q | mark matching cylinder -A- |

| q | Fitting position: Markings -B- point towards the belt pulley side |

| q | located axially by pistons |

| q | separate new conrod → Chapter |

| 5 - | Bearing shell |

| q | do not mix up used bearing shells (mark) |

| q | insert bearing shells in the centre |

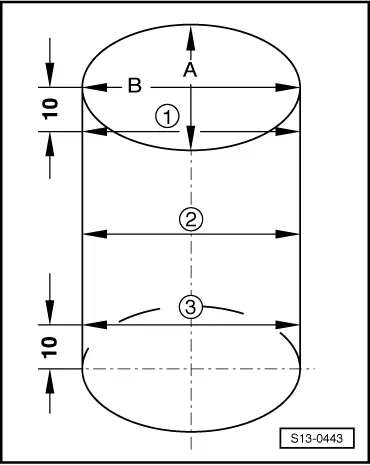

| 6 - | Cylinder block |

| q | inspect cylinder bore → Fig. |

| q | Cylinder Ø: 76.51 mm (nominal dimension) |

| 7 - | Conrod cap |

| q | as a result of the conrod separated in the cracking process, the cover fits only in one position and only to the relevant conrod |

| 8 - | Conrod bolt, 30 Nm + torque a further + 90° (1/4 turn) |

| q | replace |

| q | oil thread and head contact surface |

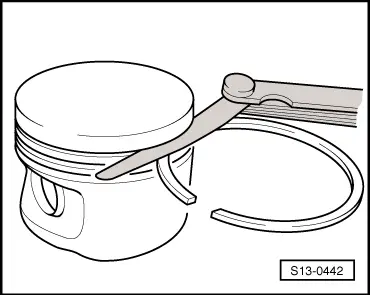

| 9 - | Oil scraper ring |

| q | carefully remove and install 3-part oil scraper rings by hand |

| q | Inspect gap clearance → Fig. |

| q | End clearance cannot be measured |

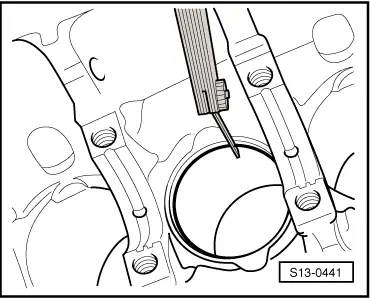

| 10 - | Compression rings |

| q | Offset joint 120° |

| q | use piston ring pliers for removing and installing |

| q | marking -TOP- must face towards piston crown |

| q | Inspect gap clearance → Fig. |

| q | Inspect end clearance → Fig. |

|

|

| Piston ring dimensions in mm | new | Wear limit |

| 1. Compression ring | 0,20…0,50 | 1,0 |

| 2. Compression ring | 0,40…0,60 | 1,0 |

| Oil scraper ring | 0,20…1,10 | no wear indication possible |

|

|

| Piston ring dimensions in mm | new | Wear limit |

| 1. Compression ring | 0,04…0,08 | 0,15 |

| 2. Compression ring | 0,02…0,08 | 0,15 |

| Oil scraper ring | cannot be measured | |

Note

Note

|

|