| Special tools and workshop equipment required |

| t

| Catch pan for workshop crane, e.g. -VAS 6208- |

| t

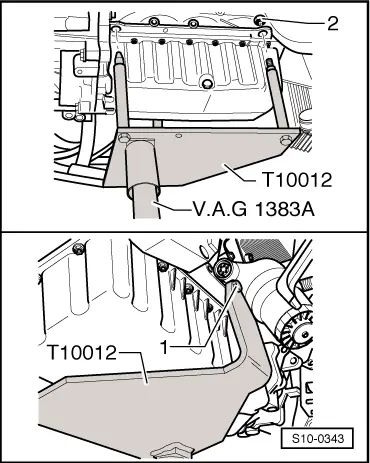

| Engine and gearbox jack, e.g. -V.A.G 1383 A- |

| t

| Workshop crane, e.g. -VAS 6100- |

| t

| Double ladder, e. g. -VAS 5085- |

| t

| Hose clamps up to Ø 25 mm -MP7-602 (3094)- |

| t

| Pliers for spring strap clamps |

Note | t

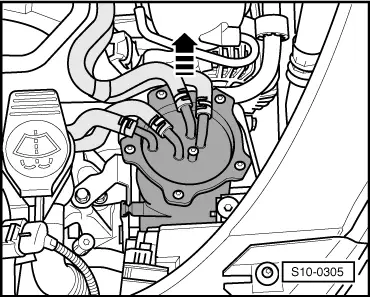

| The engine is removed downwards together with the gearbox. |

| t

| All cable straps that have been loosened or cut open when the engine was removed must be fitted again in the same location when the engine is installed again. |

| t

| Leave the car key in the ignition lock so that the steering wheel lock does not click into place. |

| t

| Collect drained coolant in a clean container for reuse or proper disposal. |

Caution | Please observe the following when undertaking all assembly work, particularly in the engine compartment, due to its cramped construction. |

| t

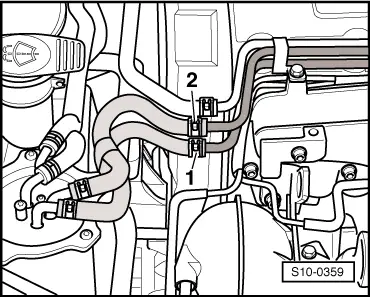

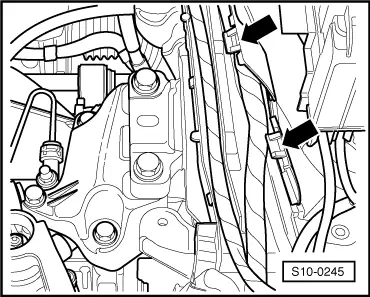

| Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling fluid and refrigerent, brake fluid, vacuum) and electrical lines in such a way that the original line guide is re-established. |

| t

| In order to avoid damage to the cables, ensure that there is adequate free access to all moving or hot components. |

|

| Observe all safety measures and notes for assembly work on the fuel and injection system, the charge air system as well as the rules for cleanliness → Chapter. |

| –

| Before disconnecting the battery, if necessary remove the adapter for the safety wheel bolts from the luggage compartment. |

WARNING |

| –

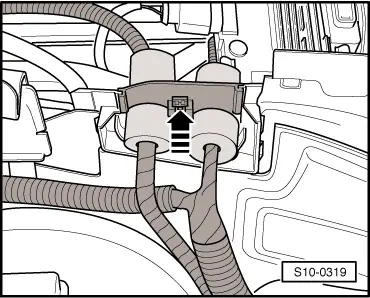

| Remove air filter with air mass meter, air intake hose and suction hose. |

| t

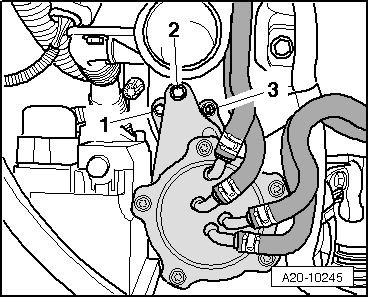

| Vehicles with engine identification characters BKD, AZV: → Chapter |

| t

| Engine identification characters BMM: → Chapter |

| –

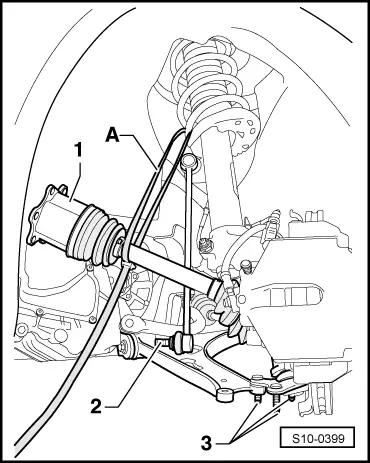

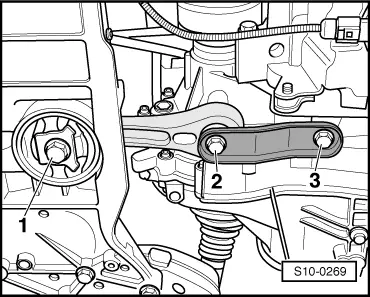

| Slacken the screw for the front right drive shaft only by maximum 90°, otherwise the wheel bearing may be damaged. |

| –

| Remove the left drive shaft from the gearbox flange. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING