| Remove the double clutch „old design“ up to 05.11 |

| Special tools and workshop equipment required |

| t

| Assembly stand -MP9-101- |

| t

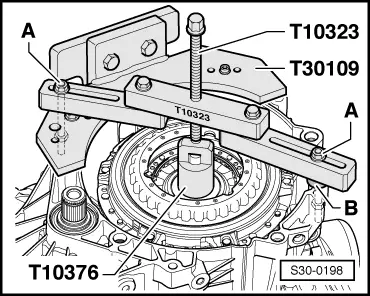

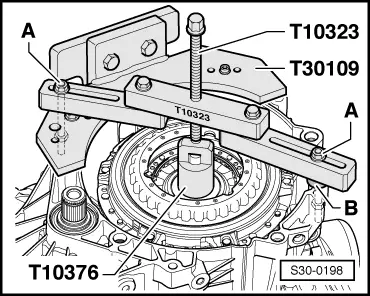

| Supporting bridge -T10323- |

| t

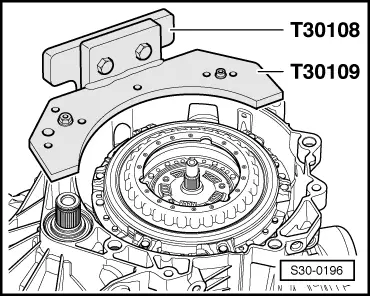

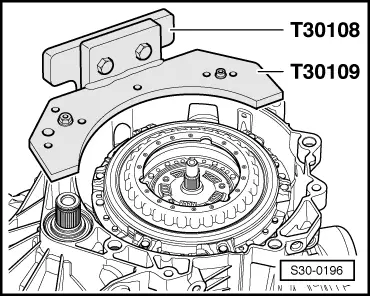

| Gearbox mount -T30109 (VW 353)- |

| l

| The mechatronics for double clutch gearbox -J743- is installed on the gearbox |

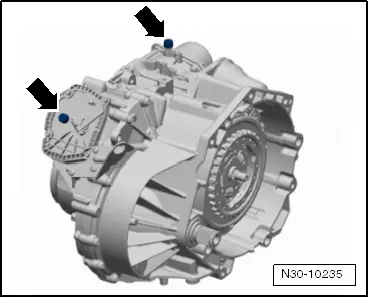

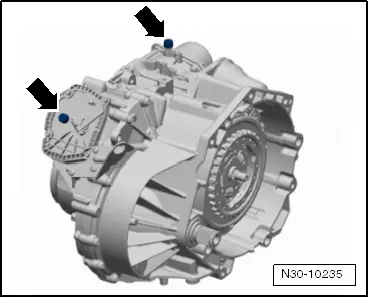

| When working on the gearbox, both ventilation caps -arrows- must be detached and must be closed in an oil-tight manner with suitable screw plugs. In case of oil leakage from the mechatronics, the mechatronics must be replaced → Electronic Catalogue of Original Parts. The »new«mechatronics for the gearbox is already precisely filled with oil at the factory. Therefore, it is only possible to fill the mechatronics with oil at the factory. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note