| Removing and installing the cylinder head |

| Special tools and workshop equipment required |

| t

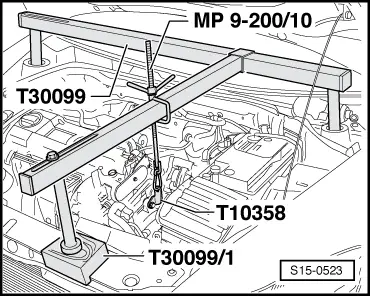

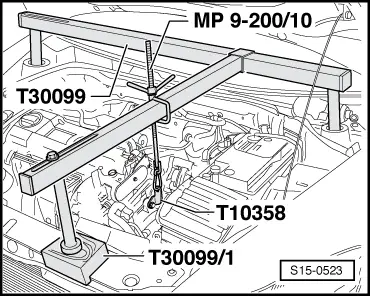

| Supporting device -T30099- |

| t

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning and degreasing agent, e.g. -D 009 401 04- |

| t

| Protective goggles and gloves |

| l

| Engine temperature should not exceed 35 °C, because the cylinder head could be twisted when slackening the screws. |

| l

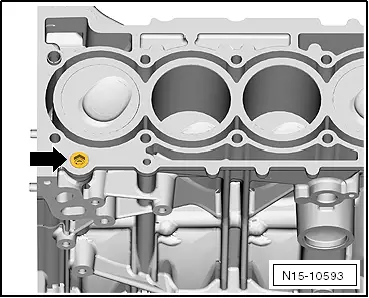

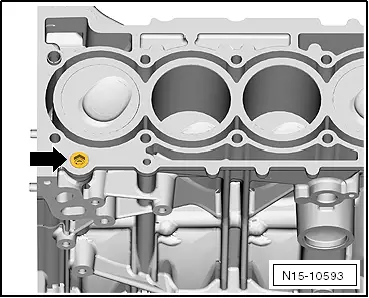

| The pistons must not be in TDC |

WARNING | Release pressure in the high pressure area of the fuel system → Chapter. |

|

| –

| Drain the coolant from the cooling system → Chapter. |

| –

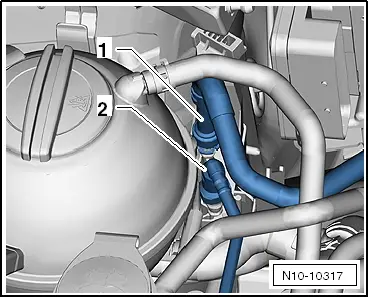

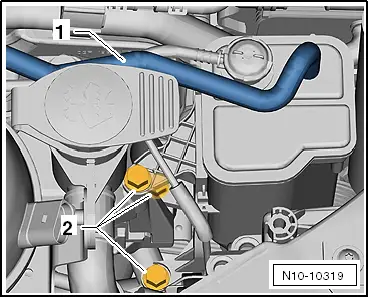

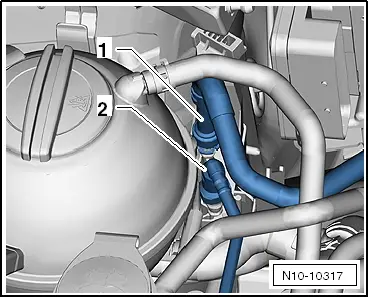

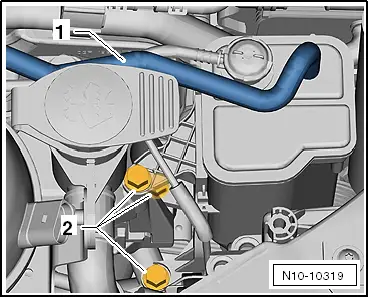

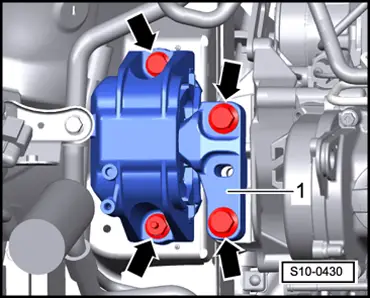

| Remove coolant regulator housing from cylinder head. |

| –

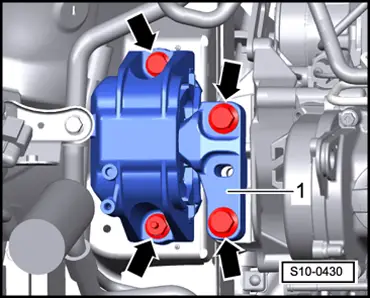

| Fit supporting device -T30099-. |

|

|

|

Note

Note

Note

Note