| Removing and installing oil pan |

| Special tools and workshop equipment required |

| t

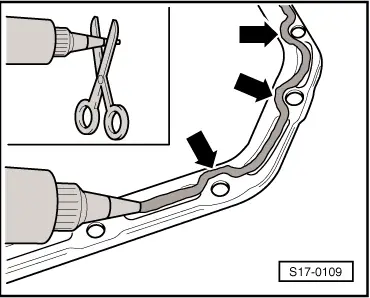

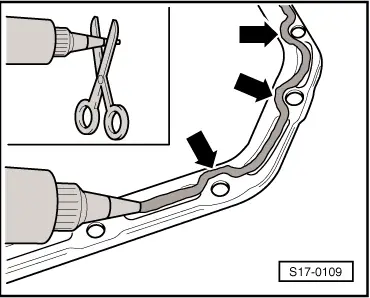

| Sealant remover gasket stripper (bearing code GST, bearing article no. R 34402), manufacturer Retech s.r.o. |

| t

| Cleaning and degreasing agent, e.g. -D 009 401 04- |

| t

| Protective goggles and gloves |

| t

| Silicone sealant -D 176 600 A1- |

| t

| Catch pan, e.g. -VAS 6208- |

| For the vehicles Fabia II, Roomster |

| –

| Remove catalytic converter with pre-exhaust pipe → Chapter. |

| For the vehicles Octavia II, Yeti |

| Continued for all vehicles |

| –

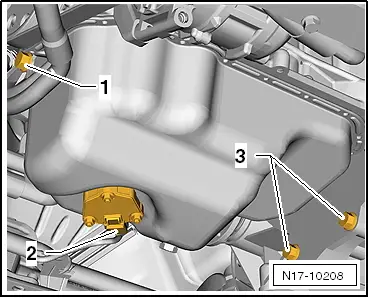

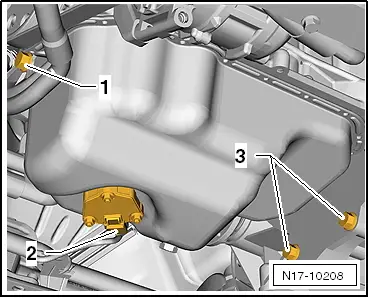

| Disconnect plug at oil level and oil temperature sender -G266-. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note