| –

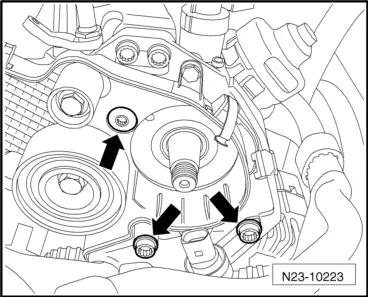

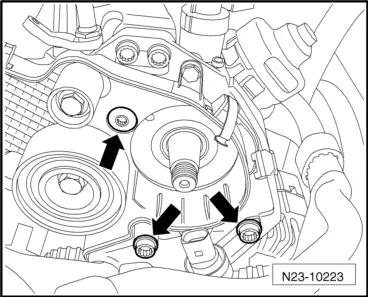

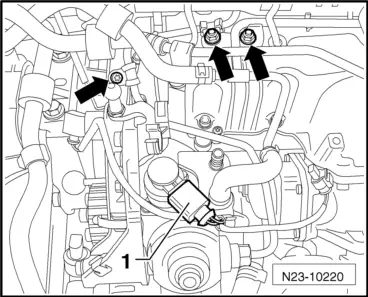

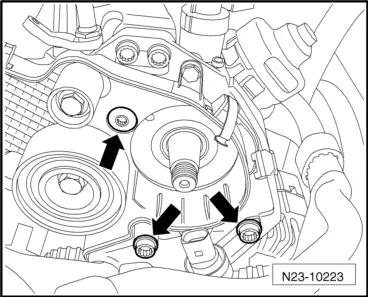

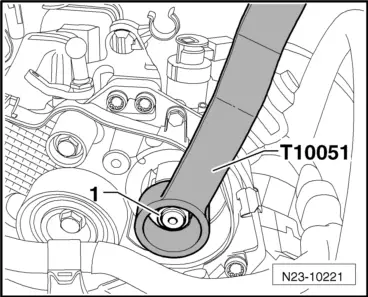

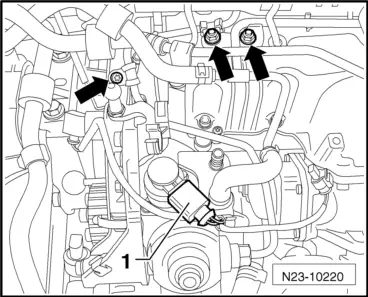

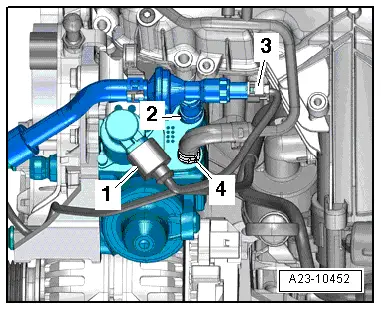

| Release the fixing screws -arrows- of the high pressure pump. |

| –

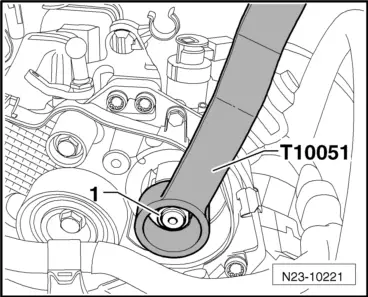

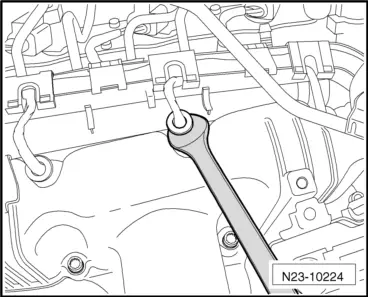

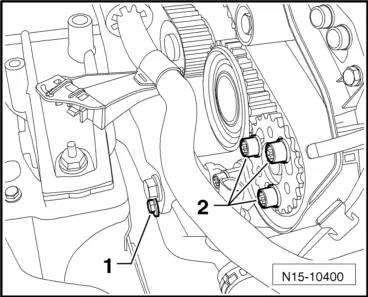

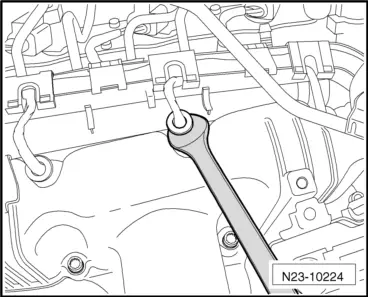

| Carefully remove the high pressure pump. |

Caution | Risk of damage to the high pressure pump through running dry. |

| t

| After reinstalling the high pressure pump: carry out the basic setting „test of fuel pump for predelivery“»3 times« before the first engine start → Vehicle diagnostic tester. |

| t

| After installing a new high pressure pump: fill up the high pressure pump with fuel before the first engine start → Chapter. |

|

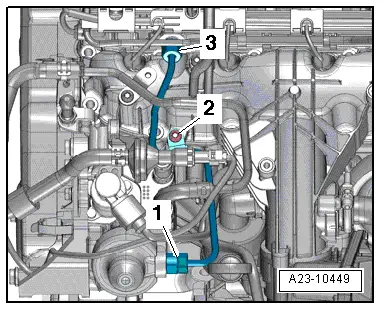

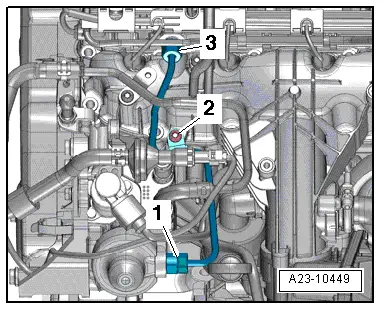

| Installation is performed in the reverse order, pay attention to the following points: |

Note | t

| When installing the high pressure pump, ensure that no dirt penetrates the fuel system. |

| t

| Only remove the screw plug immediately before installing the fuel lines. |

| t

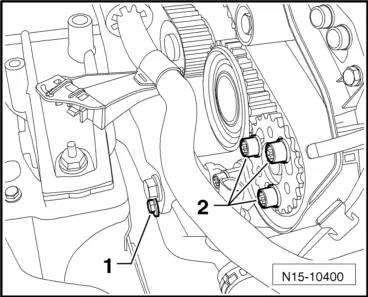

| The fixing screws for the high pressure pump must be replaced. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note