Note | t

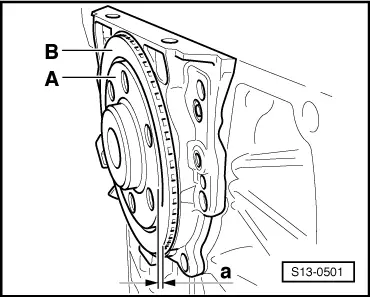

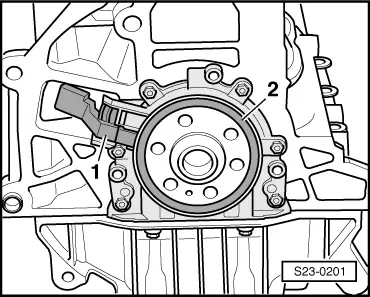

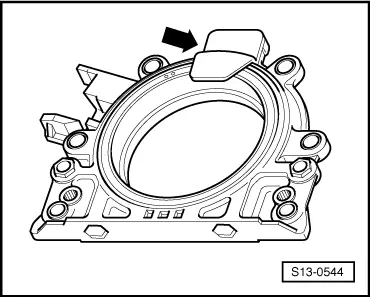

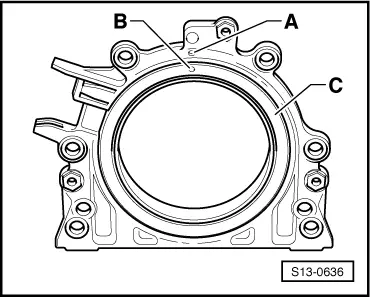

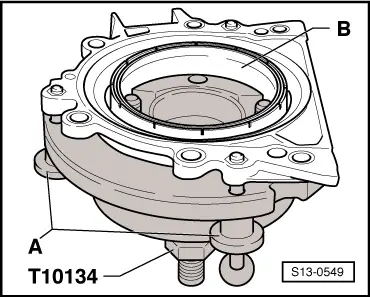

| The sealing flange with PTFE gasket ring is provided with sealing lip supporting ring. This supporting ring is intended as an assembly sleeve and must not be removed before installing. |

| t

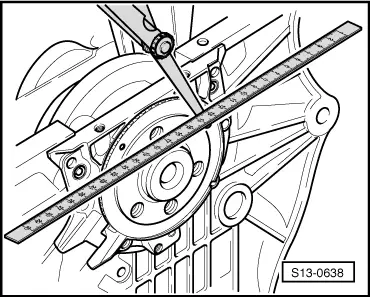

| Do not separate or turn the sealing flange and rotor after removing them from the spare part package. |

| t

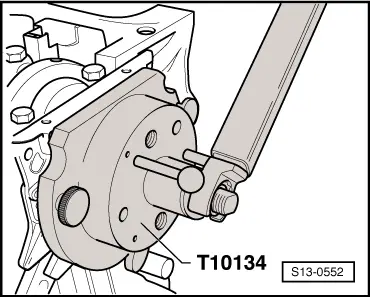

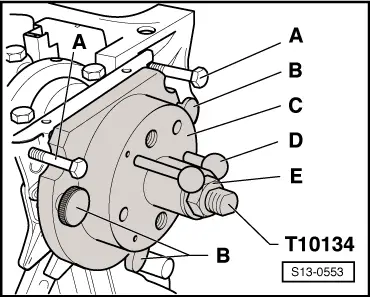

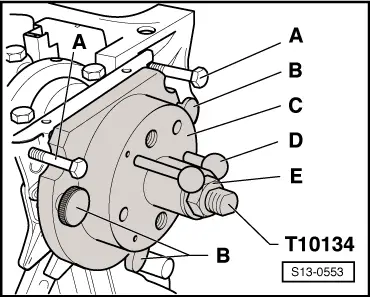

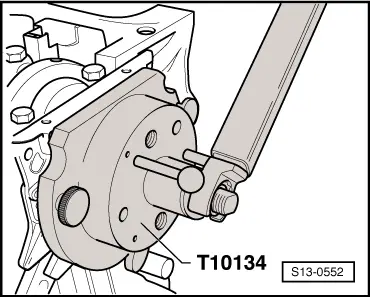

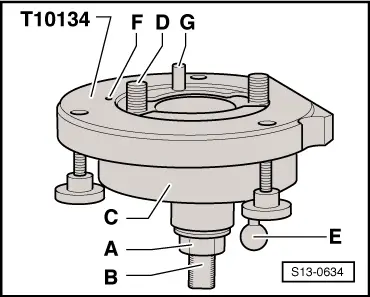

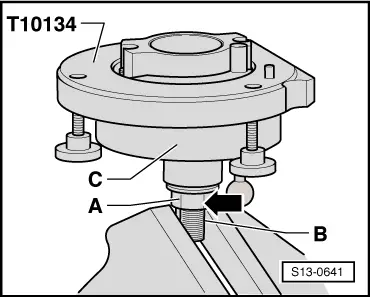

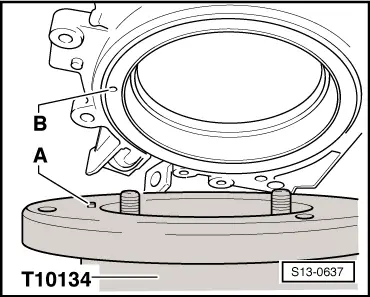

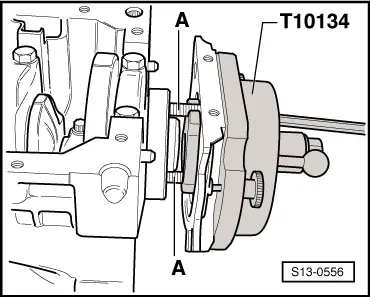

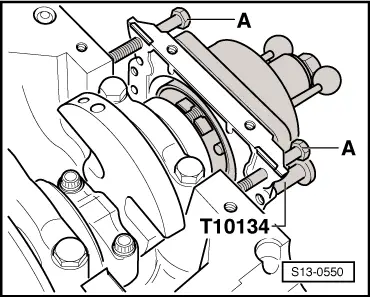

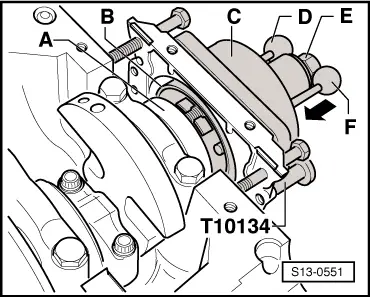

| The rotor is given its fitting location by fixing the assembly tool -T10134- to the positioning pin. |

| t

| The sealing flange and gasket ring form one unit and must be replaced together with the rotor. |

| t

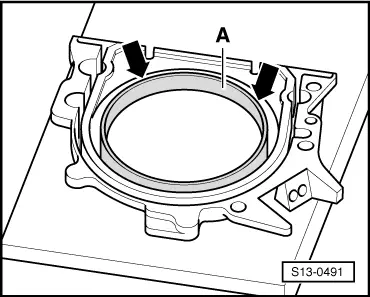

| The rotor has an elastomer layer on its sealing surface with the crankshaft. This layer must not be brought into contact with dirt or grease. |

| t

| The assembly tool -T10134- is given its fitting location to the crankshaft by means of a guide bolt, which is guided into the threaded bore of the crankshaft. |

| A - Mounting sealing flange with rotor on the assembly tool -T10134- |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note