| Repairing corrugated washer fluid level pipes - vehicles as of 01.2011 |

Note | t

| The following repair procedure of corrugated washer fluid level pipes can also be applied to vehicles manufactured up to 01.2011. |

| t

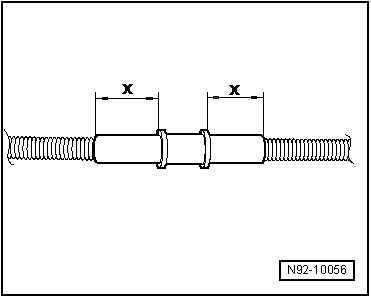

| The repair point must not be exposed to tension or flexion. |

| t

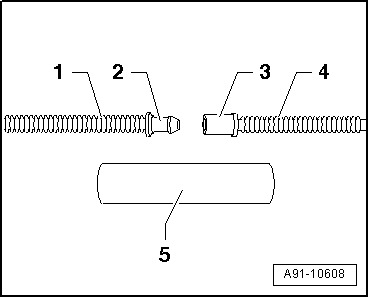

| If the damaged point is longer than 15 mm, insert new corrugated pipe and then perform the described work sequence twice. |

| Special tools and workshop equipment required |

| –

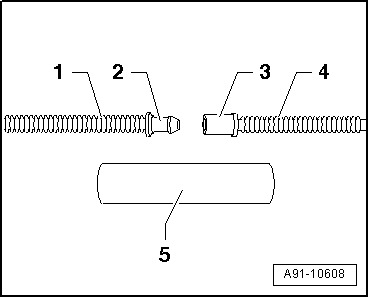

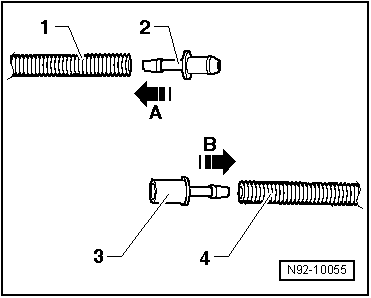

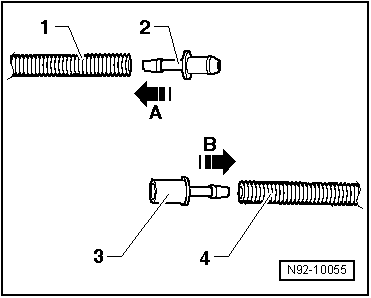

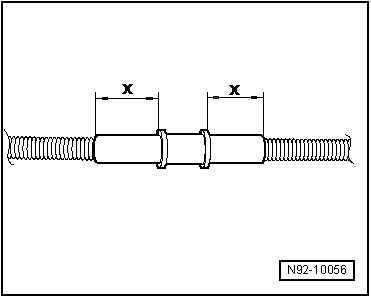

| Cut the damaged point straight out of the corrugated pipe to be repaired so that the distance between the pipe ends is maximum 15 mm. |

|

|

|

Note

Note

Note

Note