| –

| Remove the connecting pipe between the charge air cooler and the intake |

| –

| Pull the fuel feed line (with the white markings) and return line (with the blue markings) off the fuel lines (which is clipped onto the bulkhead) and catch the fuel which leaks out with a cleaning rag. |

| –

| Unclamp all connecting, cooling fluid, vacuum and air guide hoses from the engine. |

| –

| Remove/unclamp all electrical lines from the engine, gearbox, generator and starter motor and uncover them. |

| –

| Remove/unclamp all other necessary electrical cables from the engine. |

| –

| Unbolt front exhaust pipe with catalytic converter from exhaust turbocharger → Chapter. |

| –

| Unscrew the compensation bottle from the cooling system and place it to the side. |

| –

| Unscrew the vane pump for the power-assisted steering at its holder and place it to the side; hoses should remain connected up → Chassis; Rep. Gr.48. |

| –

| Observe supplementary instructions and assembly work. |

| –

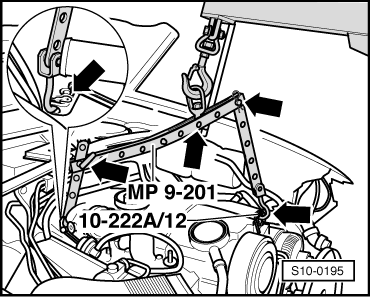

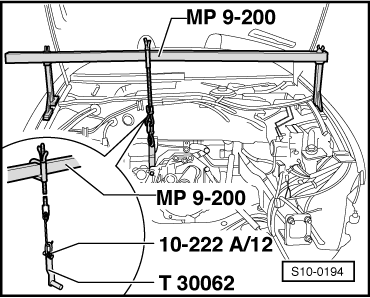

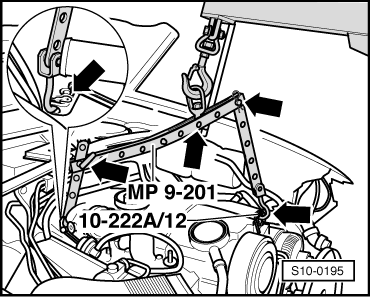

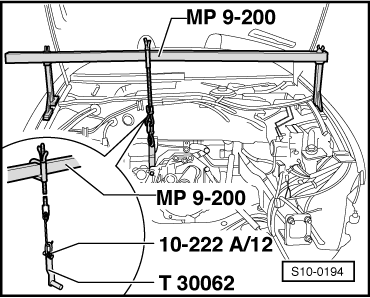

| Release engine/gearbox connecting screws at the top. |

Note | Just loosen a connecting screw, that is do not screw it right out. |

| –

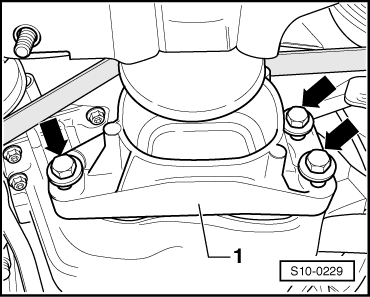

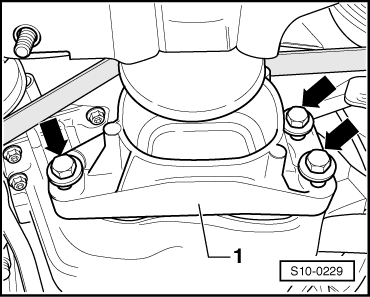

| Unscrew the top fixing nuts for the engine mounting on the right and left. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note