Superb

| Disassembling and assembling piston and conrod |

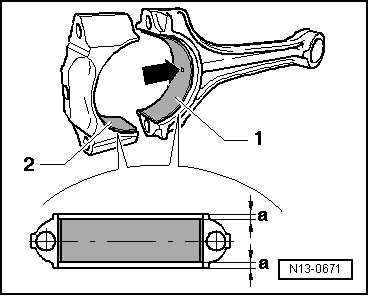

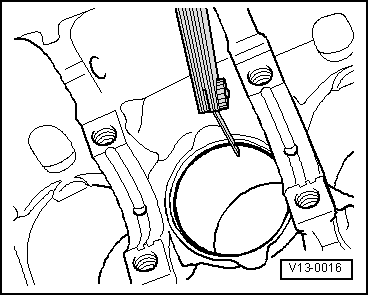

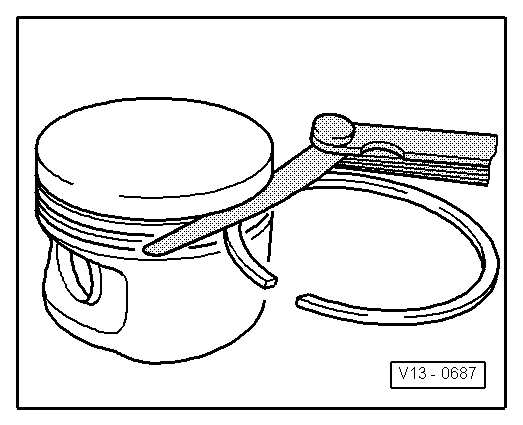

| 1 - | Piston rings |

| q | Offset joint 120 ° |

| q | use piston ring pliers for removing and installing |

| q | marking “TOP” faces piston crown |

| q | inspect gap clearance → Fig. |

| q | inspect end clearance → Fig. |

| q | oil scraper ring, 2-part or 3-part, mixed lining is admissible |

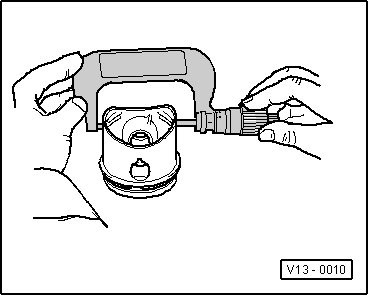

| 2 - | Piston |

| q | check → Fig. |

| q | mark installation position and matching cylinder |

| q | arrow on piston crown faces towards the belt pulley side |

| q | use piston ring tensioning strap for installing |

| q | piston Ø 80.965 mm |

| 3 - | Piston pin |

| q | if stiff, heat piston to 60°C |

| q | with drift -MP 3-400- removing and installing |

| 4 - | Circlip |

| 5 - | Conrod |

| q | with a split bearing cap |

| q | replace as a set only |

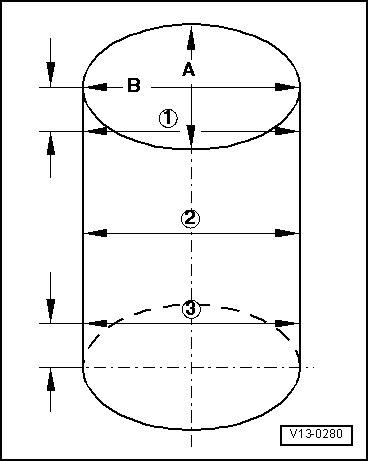

| q | mark assignment to cylinder -B- |

| q | Fitting position: markings -A- point toward belt pulley side |

| 6 - | Bearing shell |

| q | check fitting position → Fig. |

| q | do not mix up used bearing shells |

| q | Axial play when new: 0.05...0.31 mm, wear limit: 0.37 mm |

| 7 - | Cylinder block |

| q | inspect cylinder bore → Fig. |

| q | piston Ø 81.01 mm |

| 8 - | Conrod cap |

| q | Check fitting position |

| q | One result of the conrod being separated in the cracking process is that the cover only fits in one position and only to the relevant conrod |

| 9 - | Oil injection nozzle |

| q | For piston cooling |

| 10 - | Pressure relief valve, 27 Nm |

| q | Opening pressure: test pressure 0.13...0.16 MPa (1.3...1.6 bar) positive pressure |

| 11 - | Conrod bolt, 30 Nm + torque a further +90 ° (1/4 turn) |

| q | replace |

| q | oil thread and head contact surface |

|

|

|

| Piston ring | Gap clearance | ||

| new | Wear limit | ||

| Compression rings | mm | 0,20...0,40 | 0,8 |

| Oil scraper ring | mm | 0,25...0,50 | 0,8 |

|

|

| Piston ring | End clearance | ||

| new | Wear limit | ||

| Compression rings | mm | 0,06...0,09 | 0,20 |

| Oil scraper ring | mm | 0,03...0,06 | 0,15 |

|

|

Note

Note

|

|