Superb

| Disassembling and assembling pistons and conrods |

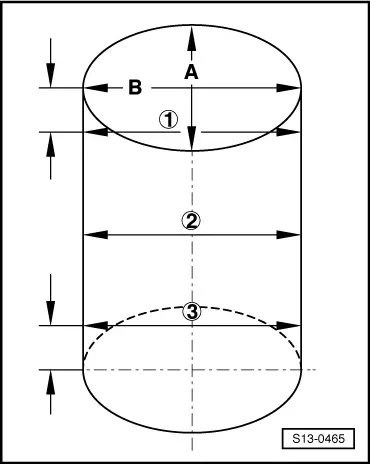

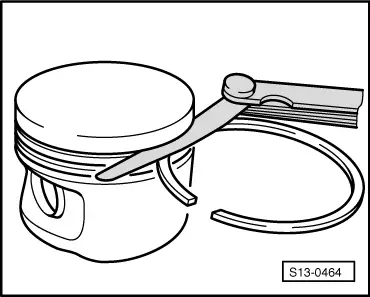

| 1 - | Piston rings |

| q | Offset joint 120° |

| q | use piston ring pliers for removing and installing |

| q | Marking “TOP” faces up |

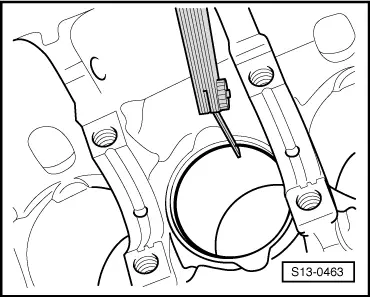

| q | Inspect gap clearance → Fig. |

| q | inspect play in the slot → Fig. |

| 2 - | Piston |

| q | with combustion chamber |

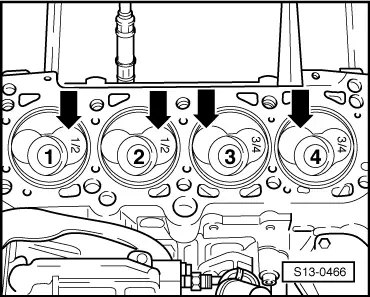

| q | mark installation position and matching cylinder |

| q | installation position and matching cylinder → Fig. |

| q | arrow on piston crown faces towards the belt pulley |

| q | use piston ring tensioning strap for installing |

| q | replace if cracks present |

| q | Check piston projection at top dead centre → Chapter |

| q | Piston dimension: Ø 80.96mm |

| 3 - | Piston pin |

| q | if stiff, heat piston to approx. 60°C |

| 4 - | Circlip |

| 5 - | Conrod |

| q | with a split cover |

| q | There must be no dirt or burrs on fracture surfaces |

| q | separate new conrod → Chapter |

| q | Pay attention to the part number |

| q | always replace as a set only |

| q | pay attention to correct installation position |

| q | mark matching cylinder -A- |

| q | Fitting position: Markings -B- point towards the belt pulley |

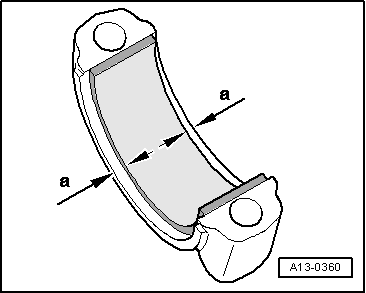

| 6 - | Bearing shell |

| q | Observe version: top bearing shell (towards the piston) must be made from a long lasting material |

| q | Distinguishing feature: black marking on the contact surface near the separation point |

| q | do not mix up used bearing shells |

| q | Insert bearing shells in the centre → Fig. |

| q | check for firm seating |

| q | Axial clearance: Wear limit 0.37 mm |

| 7 - | Cylinder block |

| q | inspect cylinder bore → Fig. |

| q | Cylinder dimension: Ø 81.01 mm |

| 8 - | Conrod bearing cap |

| q | cracked cover fits only in one position at the relevant conrod |

| q | There must be no dirt or burrs on fracture surfaces |

| q | pay attention to correct installation position |

| q | mark matching cylinder -A- |

| q | Fitting position: Markings -B- point towards the belt pulley |

| 9 - | Oil injection nozzle |

| q | for piston cooling |

| 10 - | 25 Nm |

| q | replace without sealant |

| 11 - | Conrod bolt, 30 Nm + torque a further + 90° (1/4 turn) |

| q | replace |

| q | Oil thread and contact surface |

|

|

|

|

| Piston ring | New mm | Wear limit mm |

| 1. Compression ring | 0,20...0,40 | 1,0 |

| 2. Compression ring | 0,20...0,40 | 1,0 |

| Oil scraper ring | 0,25...0,50 | 1,0 |

|

|

| Piston ring | New mm | Wear limit mm |

| 1. Compression ring | 0,06...0,09 | 0,25 |

| 2. Compression ring | 0,05...0,08 | 0,25 |

| Oil scraper ring | 0,03...0,06 | 0,15 |

Note

Note

|

|