Superb

Note

Note

|

| 1 - | Gearbox housing |

| q | is made out of aluminium or magnesium → Chapter |

| q | assign → Electronic Catalogue of Original Parts |

| 2 - | Adjusting washer S2 |

| q | Note thickness |

| q | Setting overview → Chapter |

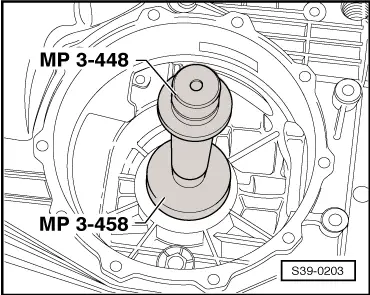

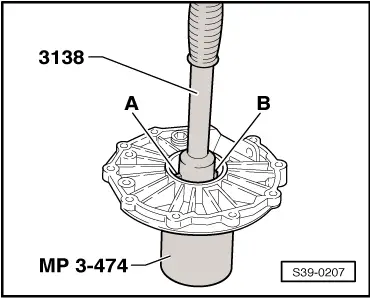

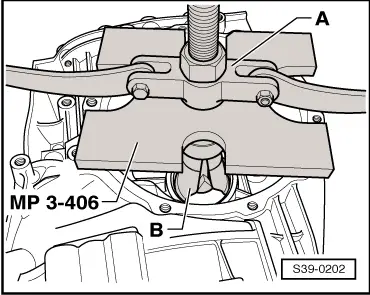

| 3 - | Right outer ring/tapered-roller bearing |

| q | removing → Fig. |

| q | installing → Fig. |

| 4 - | Right inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

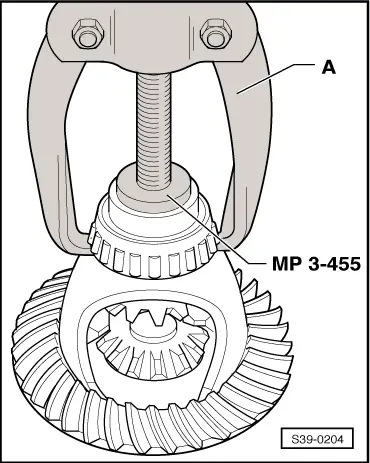

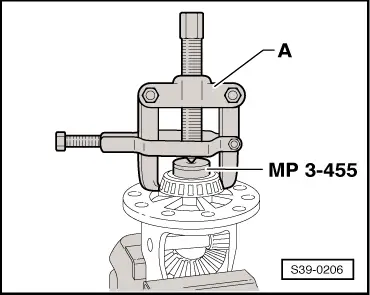

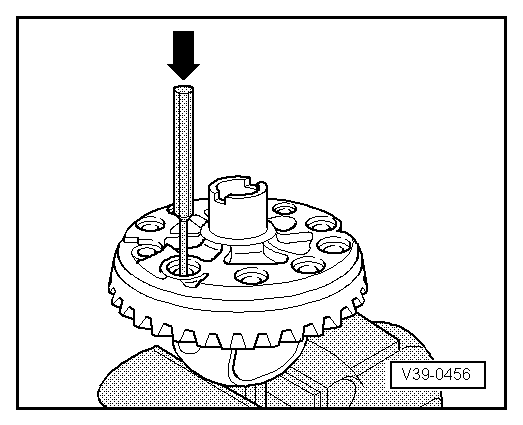

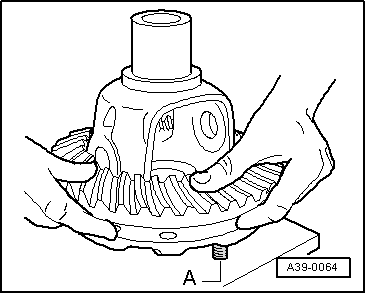

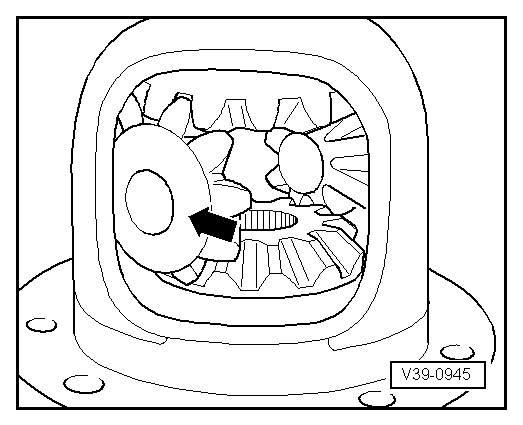

| 5 - | Crown wheel |

| q | paired with secondary shaft (drive train) |

| q | Assign the components by gearbox code letters → Chapter via the → electronic catalogue of original parts. |

| q | drive out with drift pin → Fig. |

| q | mounting on differential housing → Fig. |

| 6 - | Differential housing |

| q | left bearing assembly modified as of 05.03 |

| q | Assign the components by gearbox code letters → Chapter via the → electronic catalogue of original parts. |

| 7 - | 60 Nm and torque a further 45° |

| q | always replace → Electronic Catalogue of Original Parts |

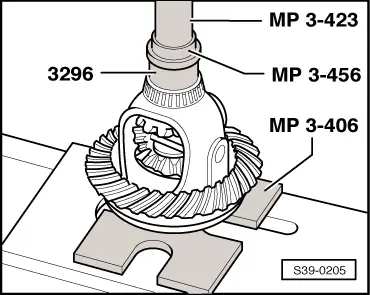

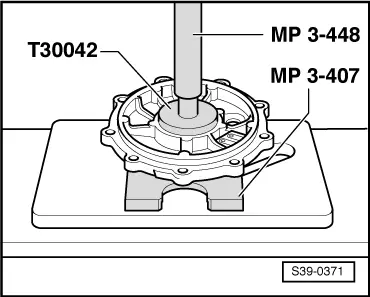

| 8 - | Left inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

Note

Note| As of 05.03 the differential housing of the bearing assembly for the left tapered-roller bearing was provided with a large radius at the inner stop. The left inner ring/tapered-roller bearing was adapted equivalently. Tapered-roller bearings of old fitting status must no longer be mounted in the new differential housings. |

| q | assign → Electronic Catalogue of Original Parts |

| 9 - | Drive wheel for speedometer |

| q | removing and installing → Chapter |

| q | the drive gear must be carefully installed and without tilting onto the differential gear |

| q | do not excert any force otherwise the drive wheel can break |

| q | as of 06.03 is no longer fitted on vehicles with ABS |

| 10 - | Left outer ring/tapered-roller bearing |

| q | left tapered-roller bearing modified as of 05.03 |

| q | Assign the components by gearbox code letters → Chapter via the → electronic catalogue of original parts. |

| q | extracting → Fig. |

| q | installing → Fig. |

| 11 - | Adjusting washer S1 |

| q | Note thickness |

| q | Setting overview → Chapter |

| 12 - | Cover |

| q | for final drive |

| 13 - | Differential bevel gear large |

| q | installing → Fig. |

| 14 - | Differential bevel gear shaft |

| q | drive out with drift |

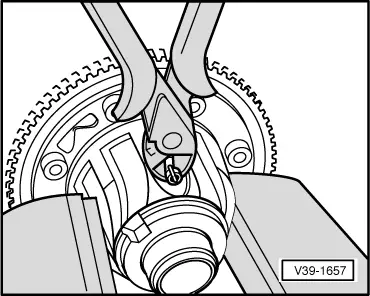

| 15 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

| q | removing and installing tensioning sleeve → Fig. |

| 16 - | Differential bevel gear small |

| q | installing → Fig. |

| 17 - | Stop disc compound |

| q | insert with gear oil |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution