Superb

Note

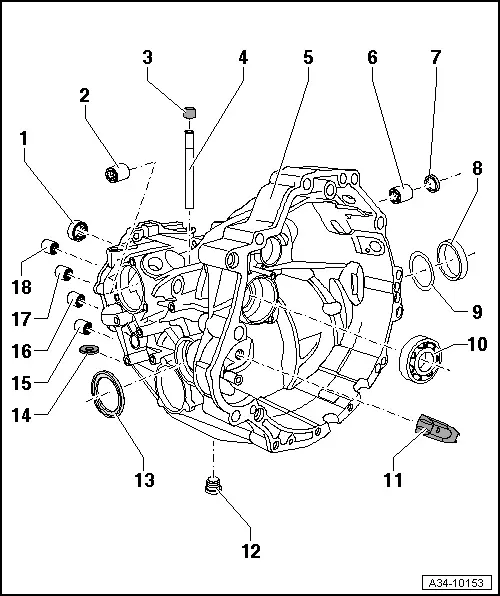

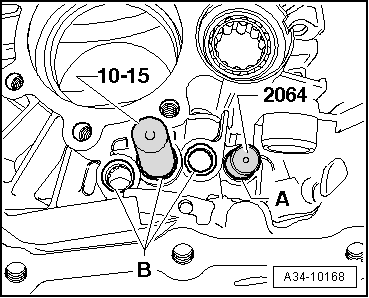

Note| On certain gearboxes, bushings for shift rods are installed instead of ball sleeves Pos. 15 to 18. Remove these bushings → Fig.. Drive in bushings with locking pin -T30044 (2064)- up to the stop. The gearbox housing was modified in combination with the bushings. Assign components via the → Electronic catalogue of original parts. |

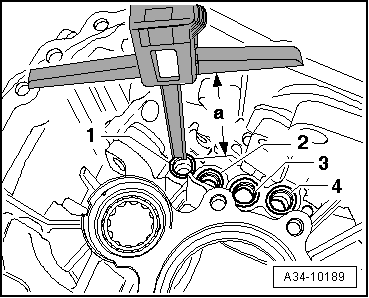

| 1 - | Needle bushing |

| q | for drive shaft |

| q | always replace → Electronic Catalogue of Original Parts |

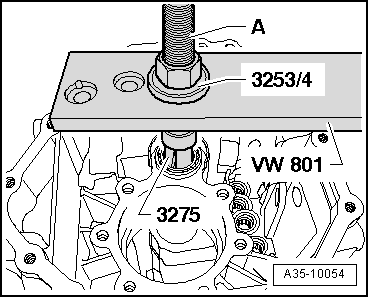

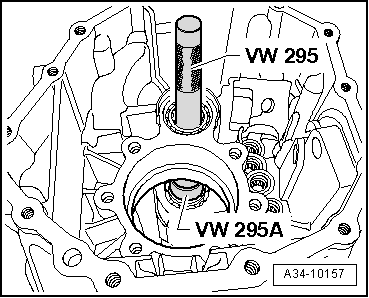

| q | removing → Fig. |

| q | inserting → Fig. |

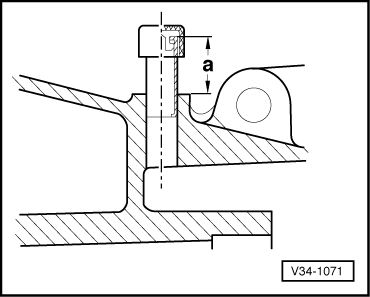

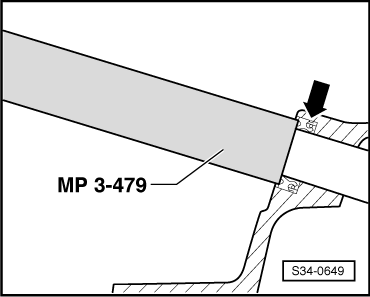

| q | measuring insertion depth → Fig.. |

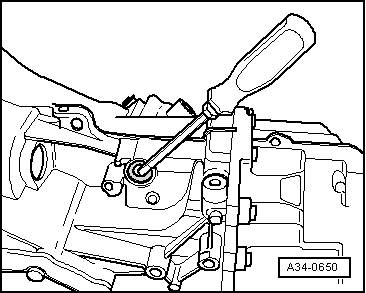

| q | after installing, secure by caulking → Fig. |

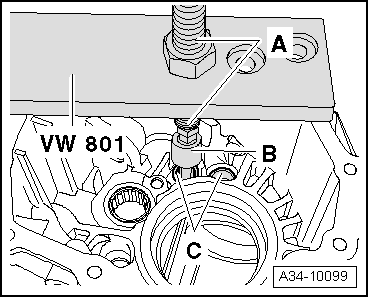

| 2 - | Ball sleeve |

| q | for gearshift shaft |

| q | removing → Fig. |

| q | driving in and securing → Fig. |

| 3 - | Cap |

| q | for gearbox bleeder |

| 4 - | Ventilation tube |

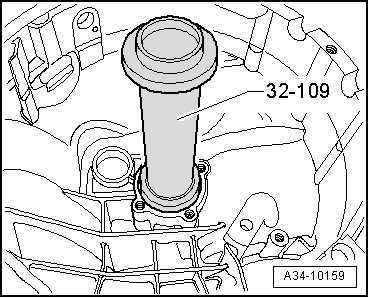

| q | Fitting dimension → Fig. |

| q | clip on cap Pos. 3 for gearbox bleeder |

| 5 - | Gearbox housing |

| q | if replaced: Deterime positioning for 2nd gear sliding gear again → Chapter, setting secondary shaft and differential (drive chain) → Chapter |

| q | modified in combination with bushings for shift rods, assign via → Electronic Catalogue of Original Parts |

| 6 - | Ball sleeve |

| q | for gearshift shaft |

| q | removing → Fig. |

| q | inserting → Fig. |

| 7 - | Gasket for gearshift shaft |

| q | can be replaced if removing (not disassembling) the gearbox → Chapter |

| q | always replace → Electronic Catalogue of Original Parts |

| q | removing → Fig. |

| q | inserting → Fig. |

| q | only mount with assembling sleeve on fitted gearshift shaft → Chapter |

| 8 - | Right outer ring/tapered-roller bearing |

| q | for differential |

| q | if replaced: Adjusting the differential gear (crown wheel) → Chapter |

| q | removing and installing → Chapter |

| 9 - | Adjusting washer “S2” |

| q | Note thickness |

| q | Setting overview → Chapter |

| 10 - | Grooved ball bearing |

| q | for drive shaft |

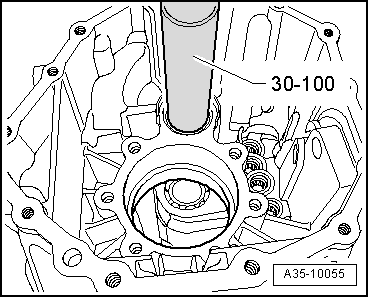

| q | remove with gearbox disassembled → Fig. |

| q | remove with gearbox removed (not disassembled) → Chapter |

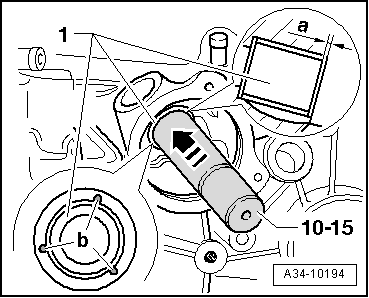

| q | installing → Fig. |

| 11 - | Intermediate piece |

| q | replace if damaged |

| 12 - | Oil drain plug - 40 Nm |

| 13 - | Gasket ring |

| q | for right flange shaft |

| q | replace → Chapter |

| 14 - | Magnet |

| q | cleaning |

| q | insert into housing rib |

| 15 - | Ball sleeve |

| q | for reverse gear shift rod |

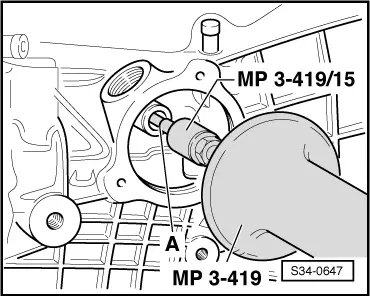

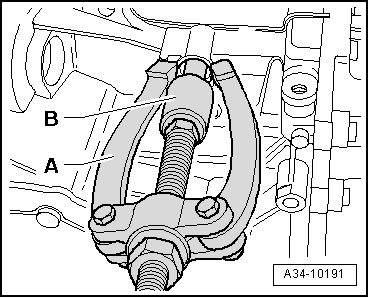

| q | removing → Fig. |

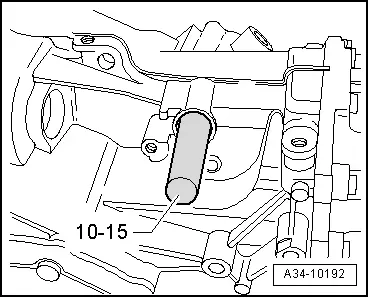

| q | inserting → Fig. |

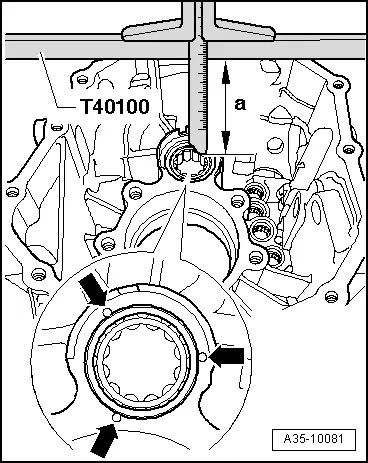

| q | measuring insertion depth → Fig.. |

| q | Change: on certain gearboxes a bushing is fitted instead of the ball sleeve |

| 16 - | Ball sleeve |

| q | for 1st and 2nd gear shift rod |

| q | removing → Fig. |

| q | inserting → Fig. |

| q | measuring insertion depth → Fig.. |

| q | Change: on certain gearboxes a bushing is fitted instead of the ball sleeve |

| 17 - | Ball sleeve |

| q | for 3rd and 4th gear shift rod |

| q | removing → Fig. |

| q | inserting → Fig. |

| q | measuring insertion depth → Fig.. |

| q | Change: on certain gearboxes a bushing is fitted instead of the ball sleeve |

| 18 - | Ball sleeve |

| q | for 5th and 6th gear shift rod |

| q | removing → Fig. |

| q | inserting → Fig. |

| q | measuring insertion depth → Fig.. |

| q | Change: on certain gearboxes a bushing is fitted instead of the ball sleeve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|