Superb

Note

Note| If replacing the secondary shaft (drive train), refer to Setting Overview → Chapter. |

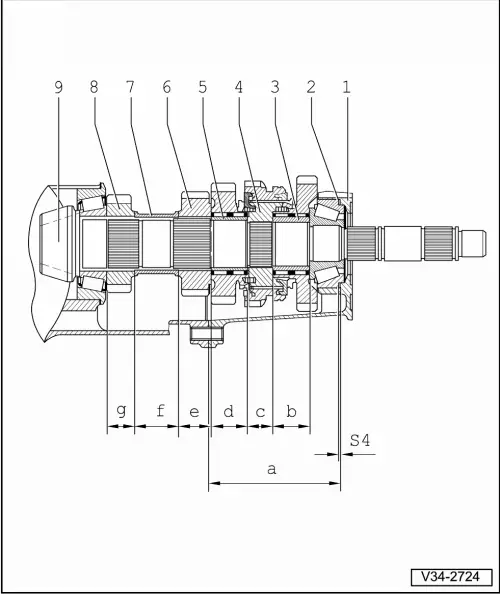

| 1 - | Bearing shield |

| 2 - | Adjusting washer S4 |

| 3 - | Inner ring for needle bearing |

| q | for 1st gear sliding gear |

| 4 - | Synchronizer body for 1st and 2nd gear |

| 5 - | Inner ring for needle bearing |

| q | for 2nd gear sliding gear |

| 6 - | 3rd gear pinion |

| 7 - | Spacer sleeve |

| 8 - | 4th gear pinion |

| 9 - | Secondary shaft |

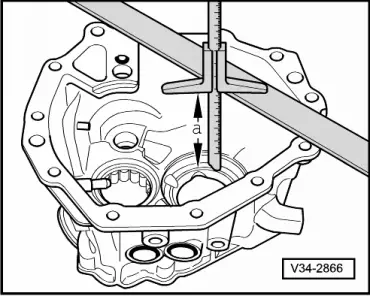

| a - | Housing depth of bearing shield |

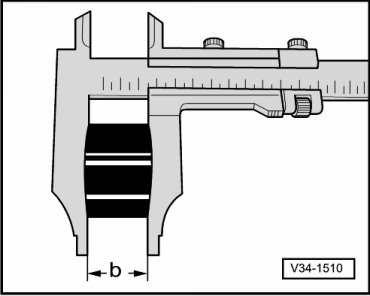

| b - | Length of inner ring for needle bearing |

| q | for 1st gear sliding gear |

| c - | Length of hub of 1st and 2nd gear synchronizer body |

| d - | Length of inner ring for needle bearing |

| q | for 2nd gear sliding gear |

| e - | Length of 3rd gear pinion |

| f - | Length of spacer sleeve |

| g - | Length of 4th gear pinion |

| S4 - | Thickness of the adjusting washer S4 |

|

Note

Note

|

|

| Depth “a” of old bearing shield | 118.40 mm |

| Depth “a” of new bearing shield | 118.65 mm |

| Difference | = 0.25 mm |

|

| Previous adjusting washer“S4” | 0.95 mm |

| Difference | + 0.25 mm |

| New adjusting washer “S4” | = 1.20 mm |

Note

Note

Note

Note

|

|

|

| Length “b” of old inner ring | 33.35 mm |

| Length “b” of new inner ring | 33.40 mm |

| Difference | = 0.05 mm |

Note

Note

Note

Note

|