Superb

Note

Note| t | When installing new pinions or drive shaft observe the technical data → Chapter. |

| t | In case of replacement of the parts marked with 1) the adjustments need to be made. Setting overview → Chapter. |

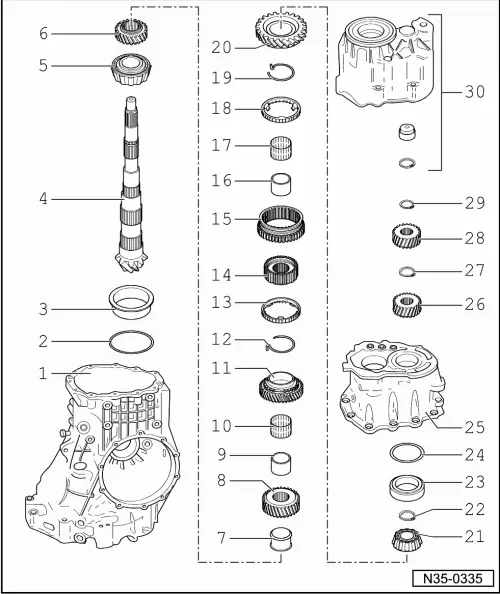

| 1 - | Gearbox housing |

| q | repairing → Chapter |

| 2 - | Adjusting washer S3 |

| q | Setting overview → Chapter |

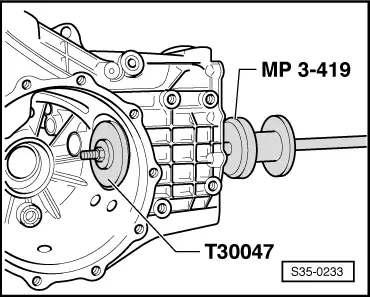

| 3 - | Outer ring/taper roller bearing, large1) |

| q | removing → Fig. |

| q | installing → Fig. |

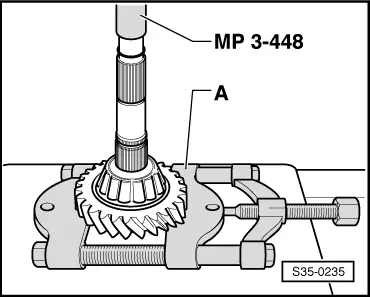

| 4 - | Secondary shaft1) |

| q | is paired with the crown wheel - if replacing, replace both |

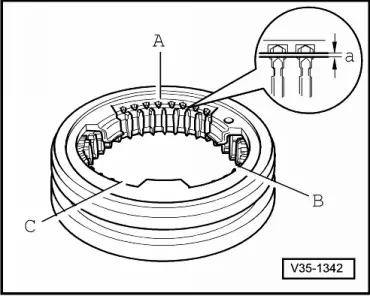

| q | Adjusting the secondary shaft and crown wheel → Chapter |

| 5 - | Inner ring/taper roller bearing, large1) |

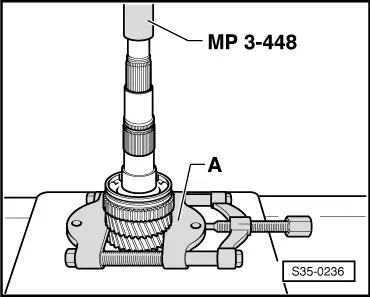

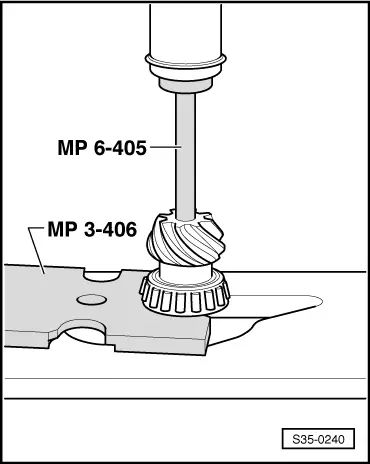

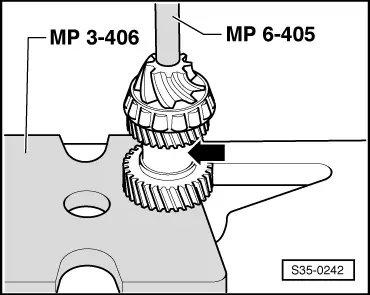

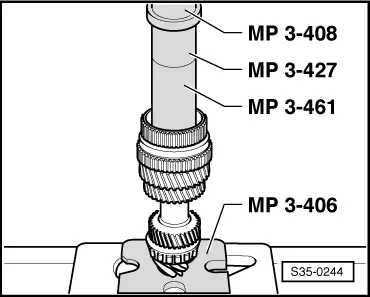

| q | pressing off → Fig. |

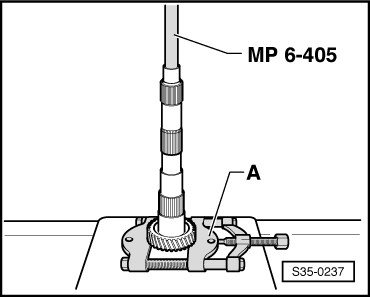

| q | pressing on → Fig. |

| 6 - | 4th gear pinion |

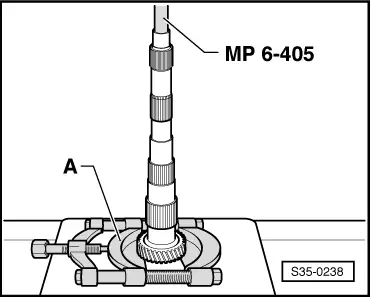

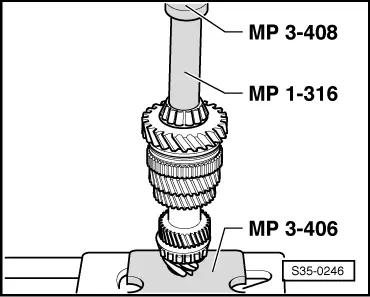

| q | pressing off → Fig. |

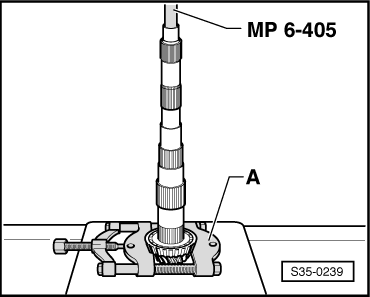

| q | pressing on → Fig. |

| 7 - | Spacer sleeve |

| 8 - | 3rd gear pinion |

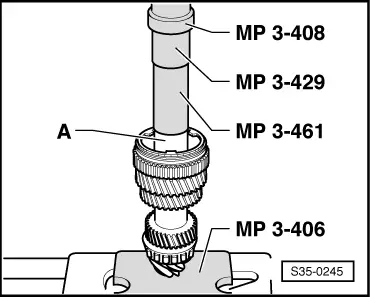

| q | press off together with inner ring Pos. 9 → Fig. |

| q | pressing on → Fig. |

| 9 - | Inner ring for needle bearing |

| q | for 2nd gear sliding gear |

| q | press off together with 3rd gear pinion Pos. 8 → Fig. |

| q | pressing on → Fig. |

| 10 - | Needle bearing |

| q | for 2nd gear sliding gear |

| q | lubricate with gear oil before installing |

| 11 - | 2nd gear sliding gear |

| q | before installing, insert spring Pos. 12 and push needle bearing Pos. 10 onto secondary shaft |

| 12 - | Spring |

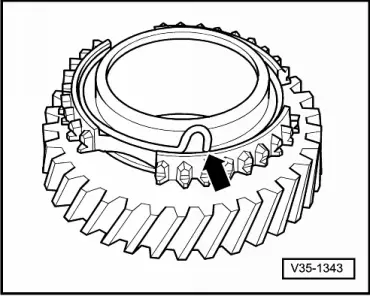

| q | insert in the 2nd gear sliding gear Pos. 11 → Fig. |

| q | Assignment to sliding gear → Electronic Catalogue of Original Parts |

| 13 - | 2nd gear synchronizer ring |

| q | coated with molybdenum |

| q | check for wear → Fig. |

| 14 - | Synchronizer body for 1st and 2nd gear |

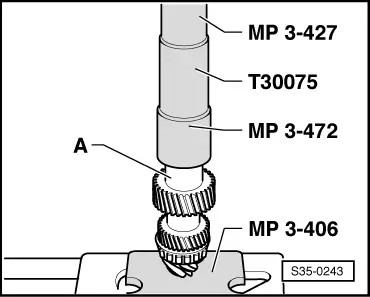

| q | pressing off → Fig. |

| q | pressing on → Fig. |

| 15 - | Sliding sleeve for 1st and 2nd gear |

| q | Fitting position: groove for selector rod facing towards 1st gear sliding gear Pos. 20 |

| 16 - | Inner ring for needle bearing |

| q | for 1st gear sliding gear |

| q | pressing off → Fig. |

| q | pressing on → Fig. |

| 17 - | Needle bearing |

| q | for 1st gear sliding gear |

| q | lubricate with gear oil before installing |

| 18 - | 1st gear synchronizer ring |

| q | check for wear → Fig. |

| 19 - | Spring |

| q | insert in the 1st gear sliding gear Pos. 20 → Fig. |

| q | Assignment to sliding gear → Electronic Catalogue of Original Parts |

| 20 - | 1st gear sliding gear |

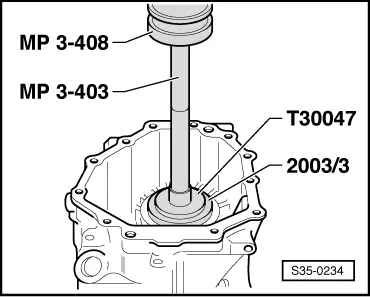

| 21 - | Inner ring/taper roller bearing, small1) |

| q | pressing off → Fig. |

| q | pressing on → Fig. |

| 22 - | Circlip |

| q | Determining thickness again → Chapter |

| 23 - | Outer ring/taper roller bearing, small1) |

| q | extracting → Fig. |

| q | installing → Fig. |

| 24 - | Adjusting washer S4 |

| q | Setting overview → Chapter |

| 25 - | Bearing shield1) |

| q | repairing → Chapter |

| 26 - | 6th gear pinion |

| q | pressing off and on → Chapter |

| q | Fitting position: collar points towards inner ring/tapered-roller bearing small |

| 27 - | Circlip |

| q | Determining thickness again → Chapter |

| 28 - | 5th gear pinion |

| q | xtracting and inserting → Chapter |

| 29 - | Circlip |

| 30 - | Cover |

| q | repairing → Chapter |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|