| t

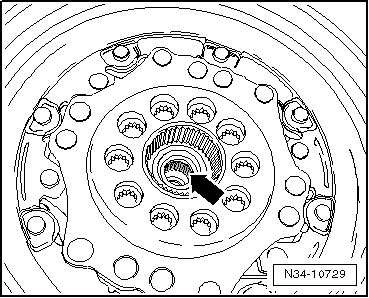

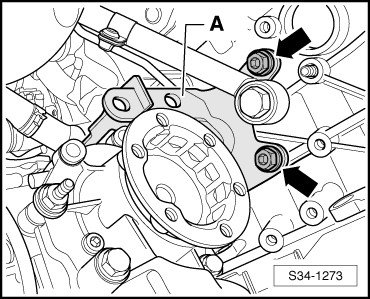

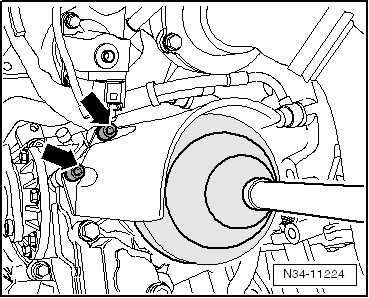

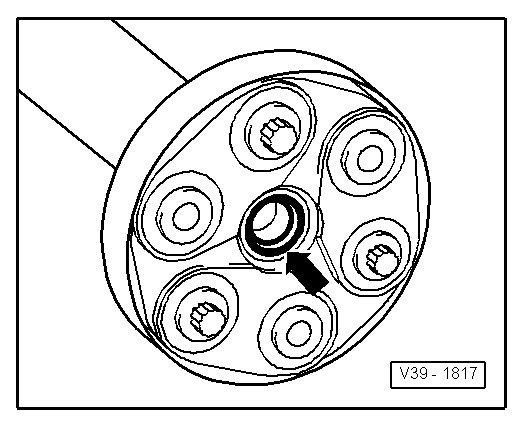

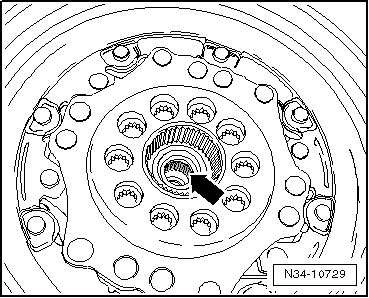

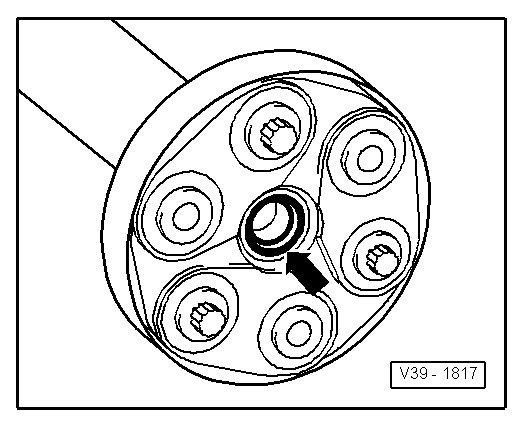

| Check the needle bearing -arrow- in the crankshaft. If it is damaged or tarnished blue (caused by overheating), it must be replaced → Engine; Rep. gr.13. |

| t

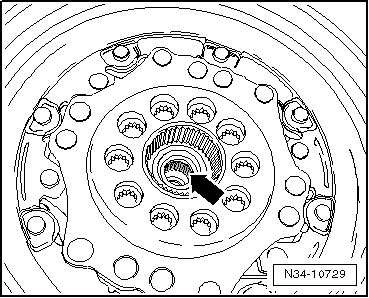

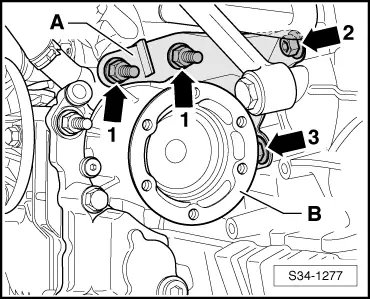

| Lightly grease the needle bearing -arrow- and the drive shaft pin (not the serration) with high-temperature grease -G 052 133 A2-. |

| t

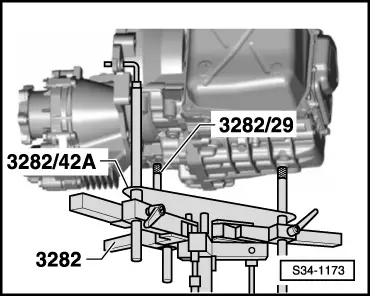

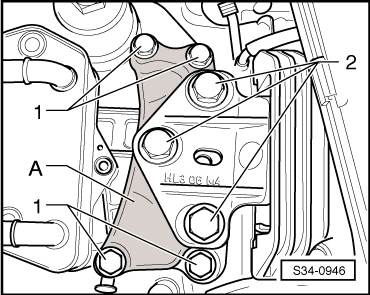

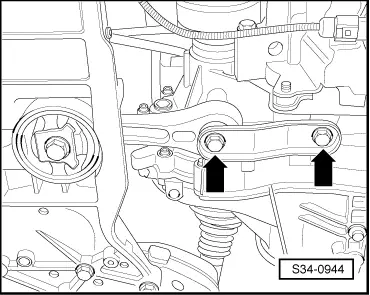

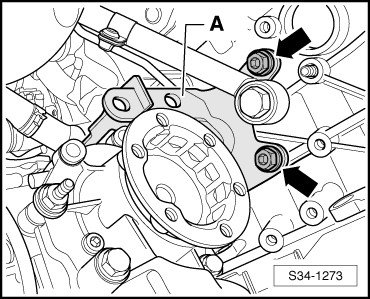

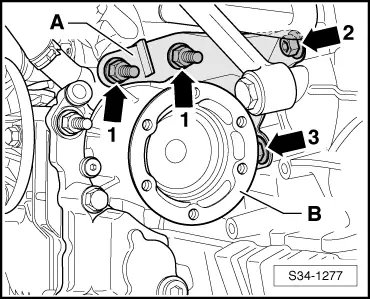

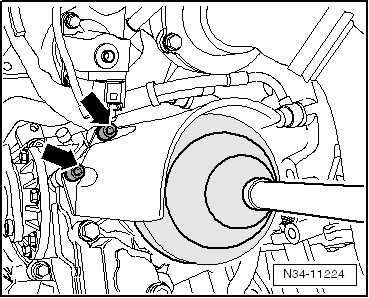

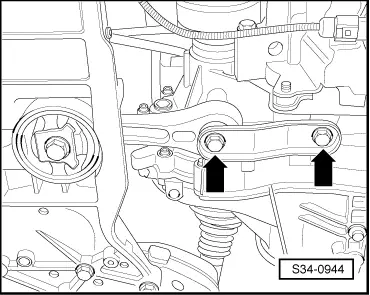

| Check whether the dowel sleeves for centering the engine/gearbox are present in the cylinder block; insert if necessary. |

| t

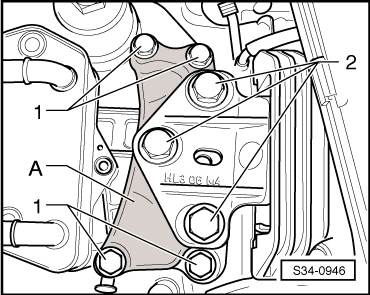

| If the gearbox is inserted, ensure the intermediate plate between the engine and gearbox is correctly installed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note