| –

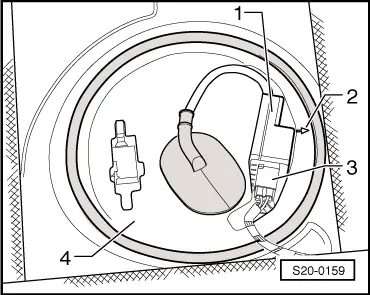

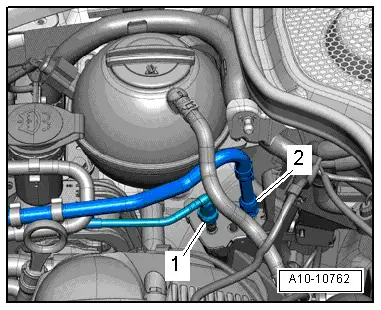

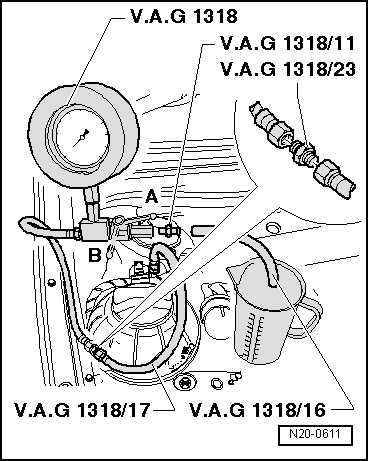

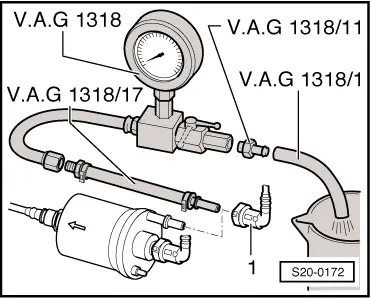

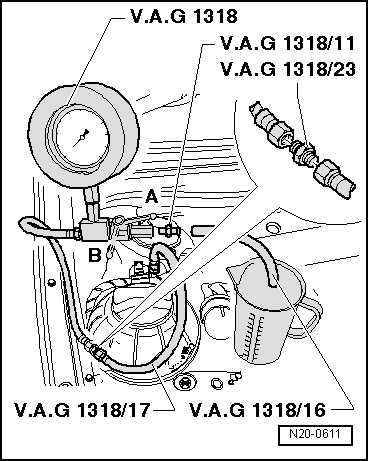

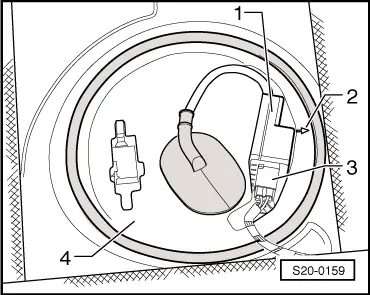

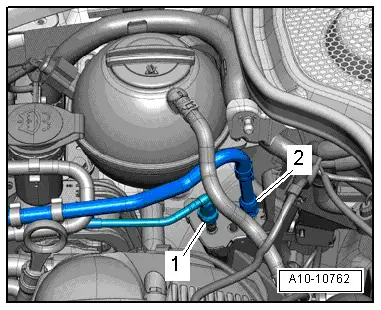

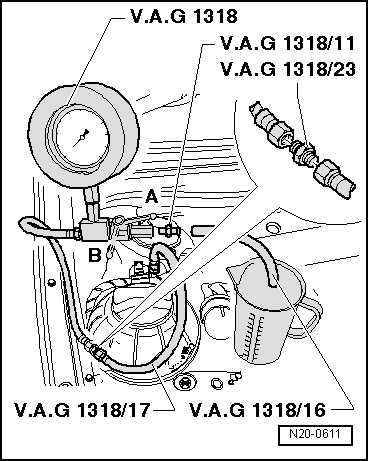

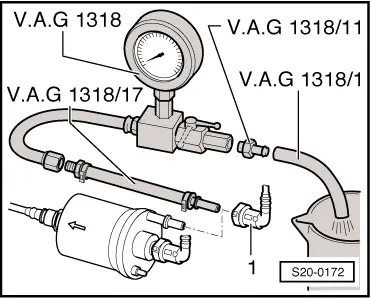

| Connect the pressure gauge - V.A.G 1318- with the double connection piece -V.A.G 1318/23 - and the adapter set -V.A.G 1318/17- to the fuel feed line. |

| –

| Fit the hose adapter -V.A.G 1318/16 - onto the adapter -V.A.G 1318/11- of the pressure measuring device and hold it in a measuring vessel. |

| –

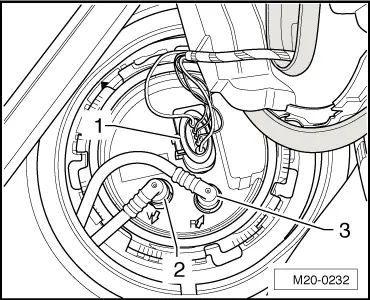

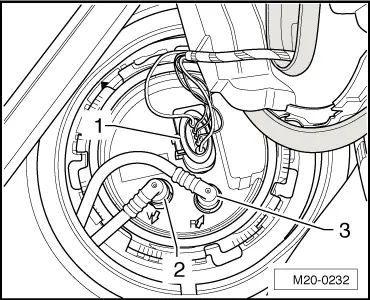

| Close the shut-off cock of the pressure measuring device. The lever then points in the position -B-. |

WARNING | Danger of liquid spraying out when opening the shut-off valve. Wear safety goggles and safety clothing, in order to avoid injuries and skin contact with fuel. Hold the container in front of the free connection to the pressure gauge. |

|

| –

| Open shut-off cock of the pressure gauge. The lever then points in the direction of flow -A-. |

| –

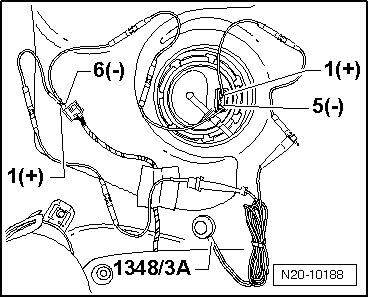

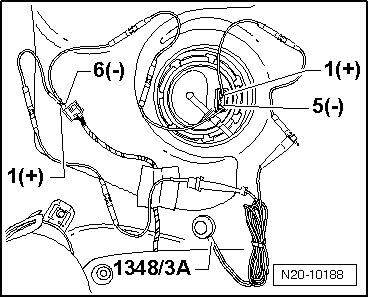

| Activate remote control -V.A.G 1348/3A -. While doing so, slowly close the shut-off cock until the pressure gauge displays 0.4 MPa (4 bar) overpressure. Now do not make any further changes to the position of the shut-off cock. |

| –

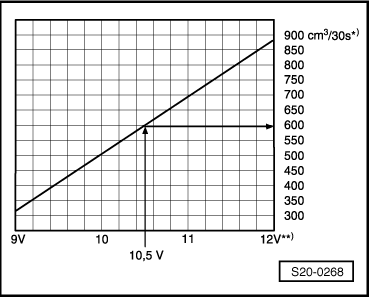

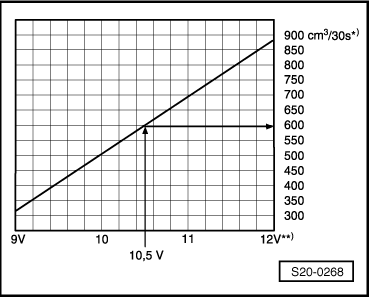

| The fuel flow rate of the fuel pump is dependent on the battery voltage. Therefore attach the multimeter -V.A.G 1715 - with adapter cables from the measuring tool set - V.A.G 1594 C- to the vehicle battery. |

| –

| Activate remote control for 30 seconds while measuring the battery voltage. |

|

|

|

Note

Note

Note

Note