|

Camshafts, Remove and Install

Remove Remove

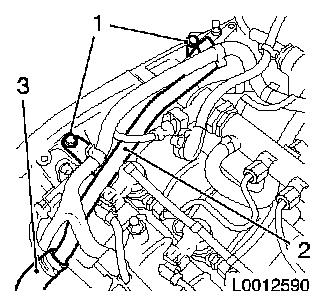

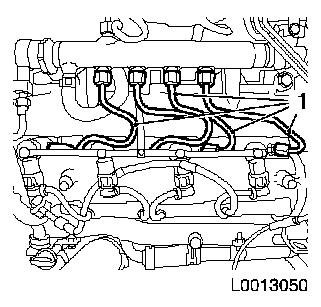

| 1. |

Remove right engine damping block adapter

|

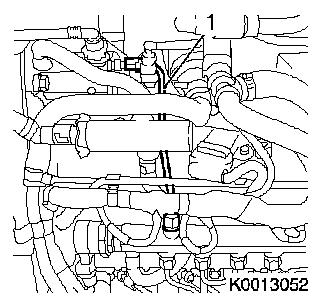

| 2. |

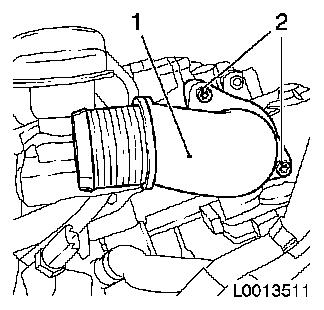

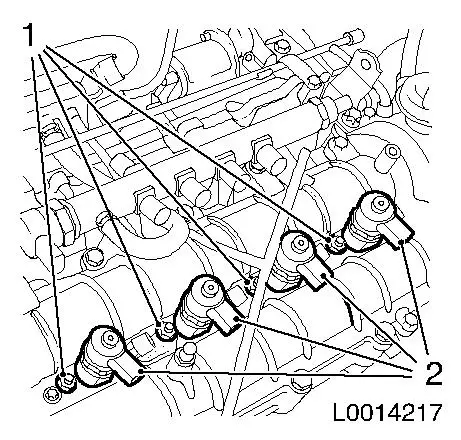

Detach engine venting pipe (2)

| • |

Detach engine venting hose (3) from engine venting pipe

|

|

|

|

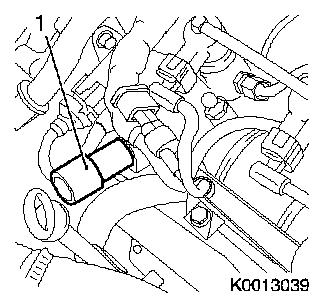

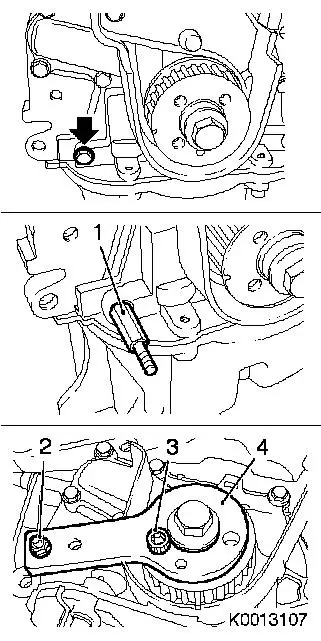

| 3. |

Install EN-46789 (1) in camshaft

housing

| • |

Unscrew exhaust camshaft closure bolt

|

|

| 4. |

Set cylinder no. 1 to TDC of combustion stroke

| • |

Rotate crankshaft in direction of engine rotation until

reference drift EN-46789 audibly engages

in exhaust camshaft

|

|

|

|

| 5. |

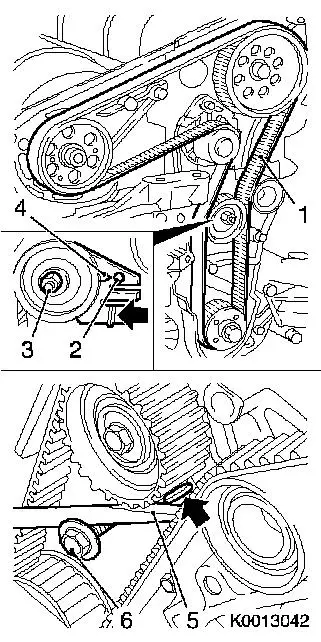

Remove toothed belt (1)

| • |

Remove toothed belt tension roller

|

|

|

|

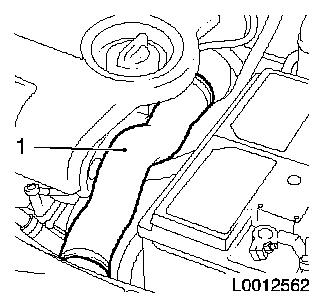

| 6. |

Remove charge air hose (1)

|

|

|

| 7. |

Detach intake connection piece (1) from throttle valve

module

|

|

|

| 8. |

Remove brake servo vacuum line

| • |

Undo quick-release fitting (1)

|

|

| 9. |

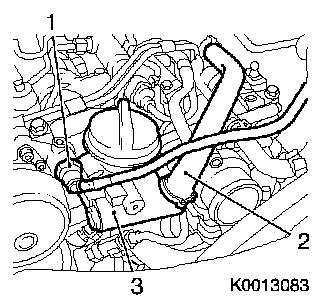

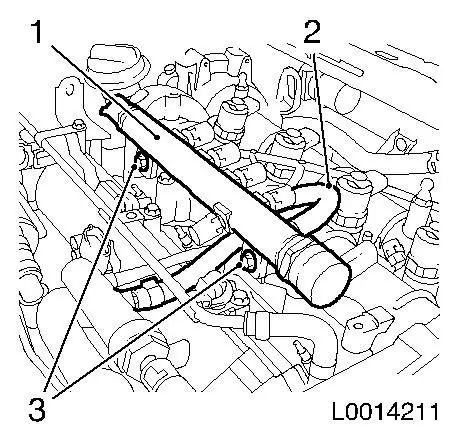

Remove engine oil filling nozzle (3)

| • |

Detach engine vent hose (2)

|

|

|

|

| 10. |

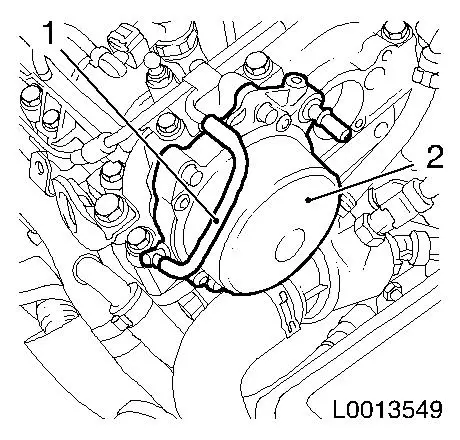

Remove vacuum pump (2)

|

|

|

| 11. |

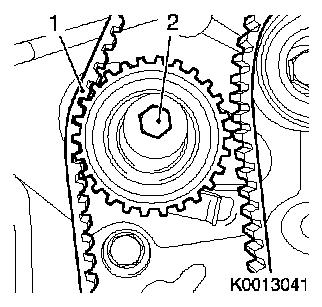

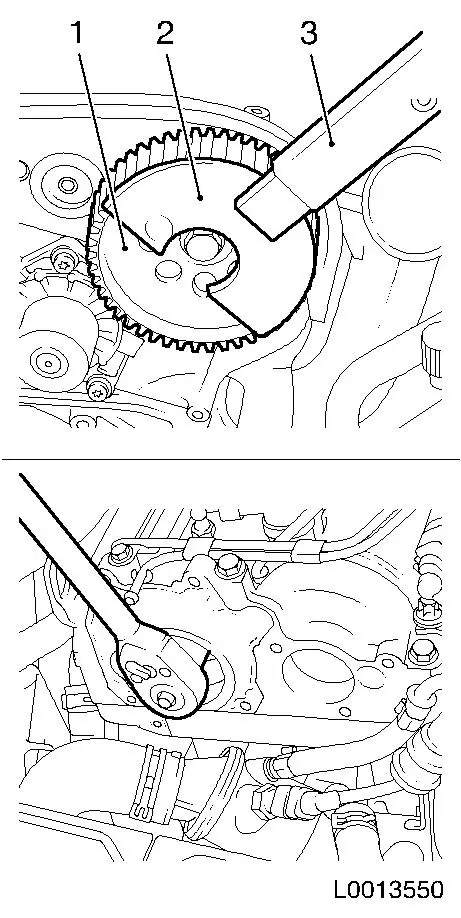

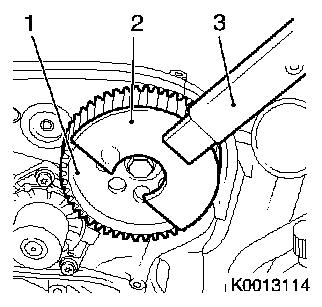

Release 2x camshaft drive gear

Note: 2nd mechanic

needed. Release intake camshaft bolt first.

| • |

Use KM-956-1 (3) in conjunction with

KM-6347 (2)

| – |

Counterhold in drive gear (1) for camshafts

|

|

|

|

|

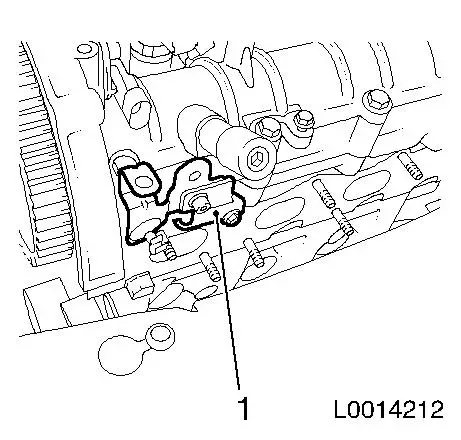

| 12. |

Release camshaft drive gear (1)

| • |

Use KM-956-1 (3) in conjunction with

KM-6347 (2)

|

|

|

|

| 13. |

Detach vacuum line from cable conduit

|

|

|

| 14. |

Detach engine management wiring harness

| • |

Disconnect 8x wiring harness plug

|

| • |

Charge pressure control solenoid valve

|

| • |

Pressure-regulating valve

|

|

| 15. |

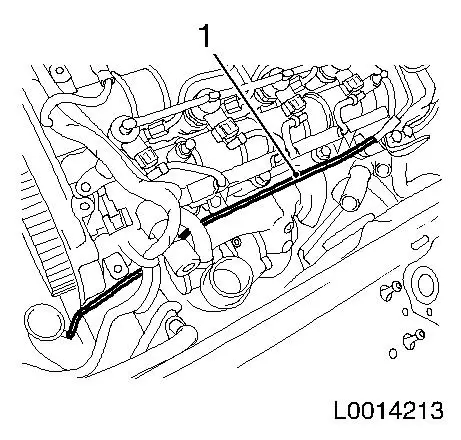

Remove vacuum line (1)

| • |

Detach 4x vacuum hoses

Note: Mark vacuum

hoses

|

|

|

|

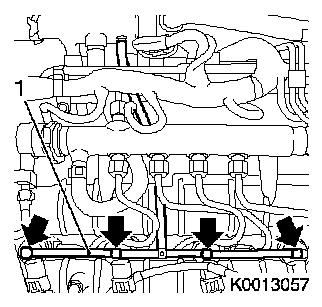

| 16. |

Detach leak oil line (1)

Note: Oil leak line may

not be detach from damping case for fuel return

| • |

Release 4x retaining clamp (arrows)

|

|

|

|

Important: When releasing the

retaining nut, counterhold with open-ended wrench against the

injector

|

| 17. |

Detach 4x high pressure line (1), pressure chamber on

injector

Important: Seal injector and

pressure chamber openings with protective caps

1)

|

| • |

Release 8x retaining nut

|

|

|

|

Important: When releasing the

retaining nut, counterhold with open-ended wrench against the

connection for the high pressure fuel pump

|

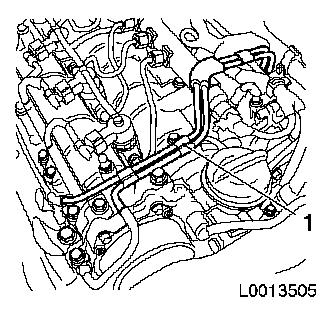

| 18. |

Remove high pressure line (1) from high pressure pump to

pressure chamber

Important: Seal pressure chamber

and high pressure pump with sealing caps

1)

|

| • |

Unscrew 2x union nuts

|

|

|

|

| 19. |

Remove accumulator (1)

|

|

|

| 20. |

Detach bracket (1) for toothed belt cover

|

|

|

| 21. |

Remove 4x injector (2)

Note: If injectors

cannot be removed by hand, use EN-46786

in conjunction with KM-328-B

Important: Seal apertures of

injectors and of pressure chamber with protective caps

|

| • |

Remove 4x injector with bracket

|

|

|

|

|

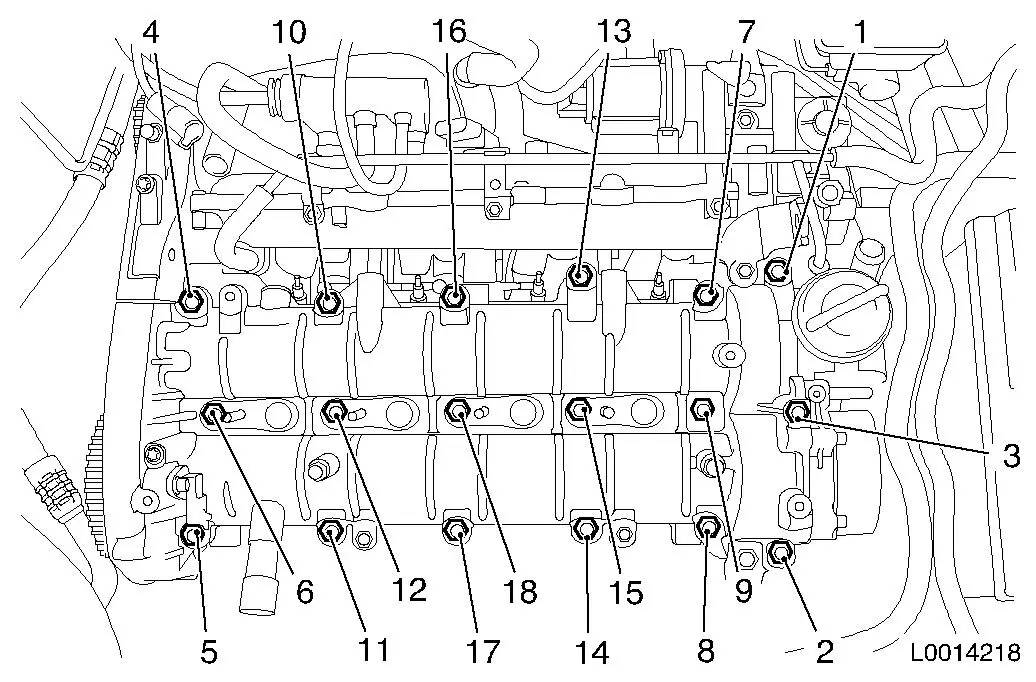

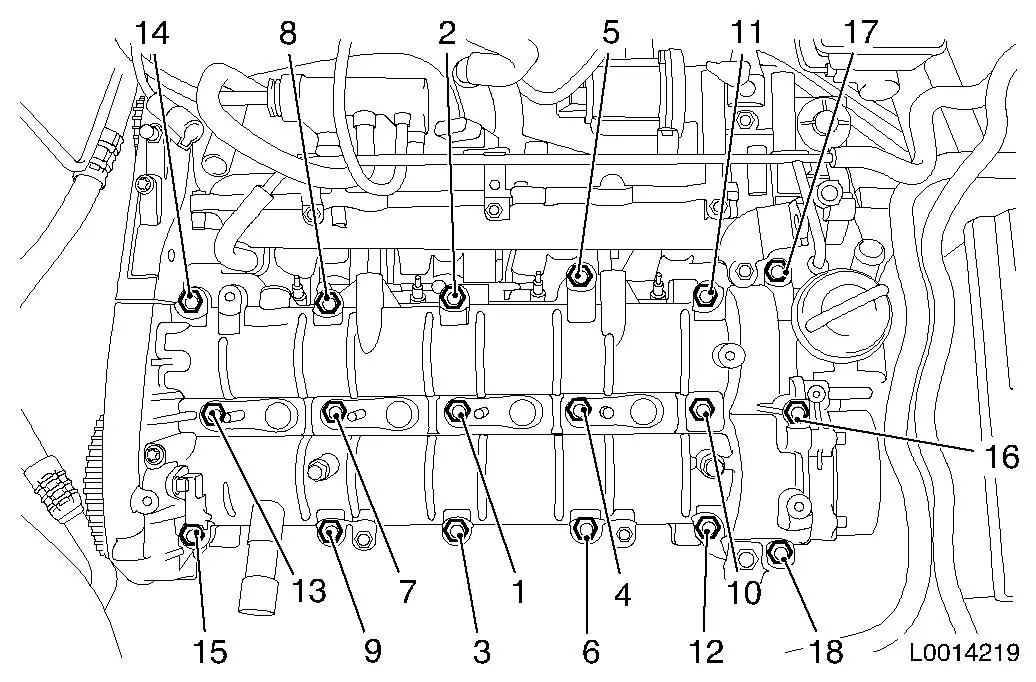

| 22. |

Detach camshaft housing

Note: Unscrew bolts

carefully in the tightening sequence stated (1 - 18). Camshaft

housing must be released evenly from cylinder head.

|

|

| 23. |

Detach 2x camshaft drive gear (3)

|

| 24. |

Remove camshaft sprocket (1)

|

|

|

| 26. |

Remove closure cap (1) of intake camshaft

Note: Do not damage

sealing surface

| • |

Remove with suitable tool

|

|

| 27. |

Remove camshaft seal ring (2)

Note: Do not damage

sealing surface.

| • |

Remove with suitable tool

|

|

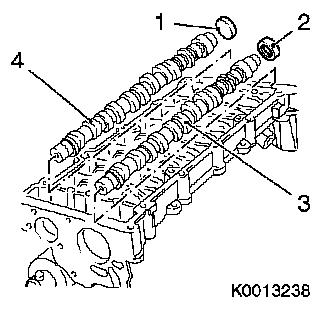

| 28. |

Remove 2x camshaft (3) and (4)

|

|

|

Install

Install

| 29. |

Install 2x camshaft

| • |

Coat bearing surfaces with engine oil

|

| • |

Insert 2x camshaft drive gear

|

Important: Use EN-46780

|

| • |

Attach seal ring for camshaft sprocket

|

| • |

Attach closure cap for intake camshaft

|

Important: Guide pin in camshaft

drive gear must engage in guide slot in camshaft sprocket

|

| • |

Attach camshaft drive gear

|

|

| 30. |

Set 2x camshaft to TDC of combustion stroke for cylinder 1

| • |

Attach EN-46789 to exhaust

camshaft

|

| • |

Attach EN-46789-100 to intake

camshaft

|

| • |

Ensure correct installation position

Note: Reference drifts

must engage audibly

|

|

| 31. |

Cleaning work

| • |

Camshaft housing, cylinder head, vacuum pump

|

|

| 32. |

Position camshaft housing

|

|

| 33. |

Tighten camshaft housing

| • |

Tighten 18x bolt in the stated order (1 - 18) 25 Nm

Note: Note different

bolt lengths

|

|

|

| 34. |

Tighten 2x camshaft drive gear

| • |

Tighten 2x new bolt 120 Nm

Note: 2nd mechanic

required

|

|

| 35. |

Clean 4x injector casing

Note: To clean the

injector seats, insert EN-47632 with

coarse fleece in the injector casing and pre-clean injector seat by

turning. Then complete cleaning process with fine fleece.

|

| 36. |

Install 4x injector

| • |

Insert 4x injector with bracket

Note: Note sequence,

cylinder 4, 3, 2, 1

|

|

| 37. |

Attach bracket, toothed belt cover

|

Important: When tightening the

retaining nut on the counterhold on the connection for the fuel

high pressure pump with open-ended wrench

|

| 39. |

Attach new high-pressure pump high-pressure line to pressure

chamber

| • |

Tighten 2x retaining nut

|

|

Important: When tightening the

retaining nut, counterhold against the injector with open-ended

wrench, Use new pressure lines

|

| 40. |

Attach 4x high pressure line for pressure chamber to

injector

| • |

Tighten 8x retaining nut

|

|

| 41. |

Attach oil leak line

| • |

Clip 4x oil leak line into injector

|

|

| 42. |

Install vacuum line

| • |

Connect 4x vacuum hoses

Note: Pay attention to

marks

|

|

| 43. |

Attach engine management wiring harness

| • |

Connect 8x wiring harness plug

|

| • |

Charge pressure control solenoid valve

|

| • |

Pressure-regulating valve

|

|

| 44. |

Clip vacuum line into cable conduit

|

| 45. |

Clean sealing surfaces.

| • |

Vacuum pump, engine oil filler port, throttle valve module

|

|

| 46. |

Install vacuum pump

| • |

Tighten 4x new bolt 5 Nm +

50°

|

|

| 47. |

Install engine oil filling nozzle

| • |

Tighten 3x bolts

Note: Recut thread

before re-using and insert bolt with locking compound (red). The

maximum installation time including torque check is 10 minutes

|

| • |

Attach engine venting hose

|

|

Warning: Connection must audibly

engage

|

| 48. |

Connect brake servo vacuum line

|

| 49. |

Attach intake port to throttle valve module

| • |

Replace gasket

Note: Coat with special

grease (white)

|

|

| 50. |

Attach intercooler charge air pipe to throttle body

|

| 52. |

Install toothed belt tension roller

Note: Insert tension

roller in guide

| • |

Screw in bolt

Note: Clean thread

before re-using and insert bolt with locking compound (red). The

maximum installation time including torque check is 10 minutes.

|

|

Important: Tightened end must be

taut

|

| 53. |

Install toothed belt

Note: Observe direction

of rotation

|

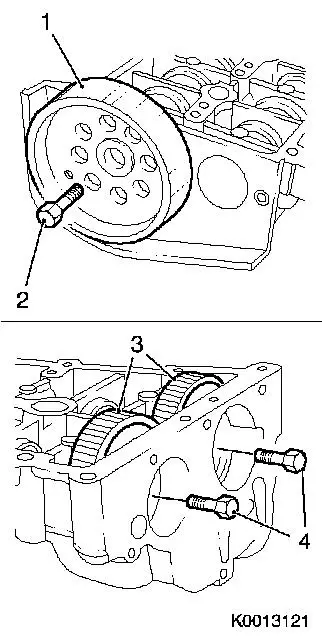

| 54. |

Lock crankshaft with EN-46788

| • |

Tighten stud bolt (1) EN-46788

|

| • |

Attach positioning disk (4) EN-46788

|

|

|

|

| 55. |

Raise vehicle by its full height

|

Important: Toothed belt tension

roller must be at maximum tension

|

| 56. |

Tension the toothed belt

| • |

Tighten bolt - toothed belt tension roller

|

|

| 57. |

Lower vehicle by its full height

|

| 58. |

Fasten camshaft drive gear

| • |

Counterhold drive gear with EN-47634

in combination with KM-956-1

|

|

| 59. |

Raise vehicle by its full height

|

| 60. |

Toothed Belt Tension, Adjust

| • |

Tension the toothed belt

Note: Push adjusting

lever in direction of arrow with a screwdriver (5) until pointer

(4) of toothed belt tension roller aligns with mark (2)

|

| • |

Tighten bolt, toothed belt tension roller (3) 25 Nm

|

|

|

|

| 61. |

Lower vehicle by its full height

|

| 62. |

Remove positioning disk EN-46788

|

| 63. |

Turn crankshaft 720° in the

direction of rotation of the engine

| • |

Rotate crankshaft in direction of engine rotation until

reference drift EN-46789 audibly engages

in exhaust camshaft

|

|

| 64. |

Check crankshaft setting with EN-46788

Note: If EN-46788 cannot be fitted, repeat the toothed belt

positioning procedure

| • |

Attach positioning disk EN-46788

|

| • |

Remove EN-46788

| – |

Unscrew stud bolt EN-46788

|

|

|

| 65. |

Remove EN-46789 from camshaft

housing

| • |

Tighten closure bolt 16 Nm

|

|

| 66. |

Attach engine venting pipe

| • |

Attach engine venting hose to engine venting pipe

|

|

| 67. |

Install right engine damping block adapter

|

1 ) Protective caps are available from the Opel

parts catalogue under catalogue number 45 06 154 / part number:

9201697

|