|

All Valve Stem Seals, Replace

| Spezialwerkzeugliste: |

- KM-194-E

- KM-6152

- KM-840

- MKM-6086

- MKM-6086-100-15

- MKM-6086-200

|

Remove Remove

Important: Observe correct

allocation and sequence

|

| 3. |

Remove 8x roller cam follower, intake side

|

Important: Observe correct

allocation and sequence

|

| 4. |

Remove 8x roller cam follower, exhaust side

|

| 5. |

Engage gear and put the handbrake on

Note: All the wheels

must be in contact with the ground

|

| 6. |

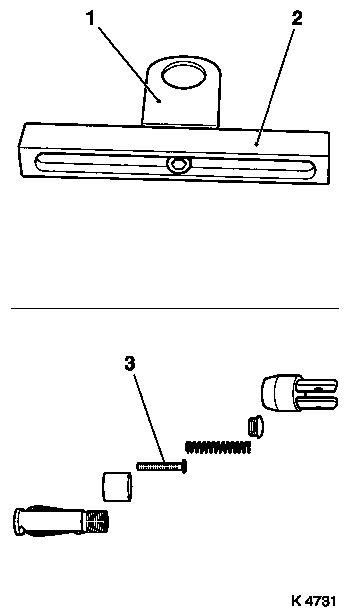

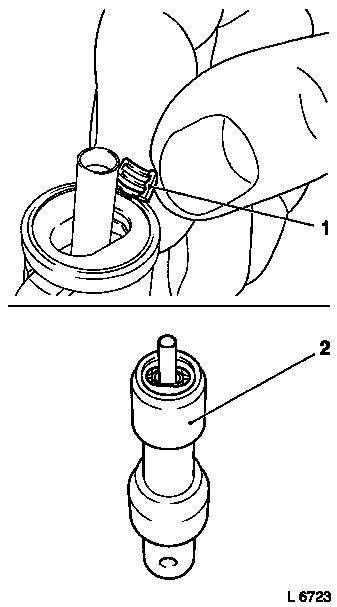

Prepare automatic valve spring lever MKM-6086

| • |

Adjust supports

Note: Fit support heads

(1) centrally on support feet (2).

|

| • |

Complete lever arm

| – |

With joint, disassembly head

|

|

| • |

Complete MKM-6086-200 assembly

head

| – |

Use MKM-6086-100-15 (3). Insert

pressure piece "6J".

Note: Note

manufacturer's provisions.

|

|

|

|

|

|

| 7. |

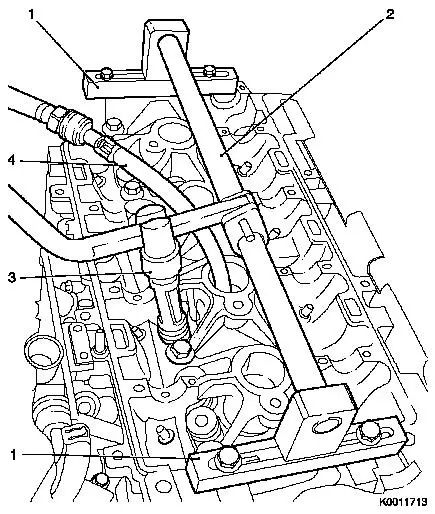

Attach automatic valve spring lever

| • |

Attach 2x supports (1)

| – |

At position camshaft bearing cap 1 and 5

|

| – |

Slide assembly shaft (2) with joint into supports

Note: Align assembly

shaft centrally via spark plug bore.

|

|

| • |

Attach lever arm

Note: Removal head (3)

must point towards the intake side.

|

|

| 8. |

Install compressed air adapter (4)

| • |

Screw into spark plug thread of cylinder 1

|

| • |

Apply compressed air to cylinder 1

|

|

|

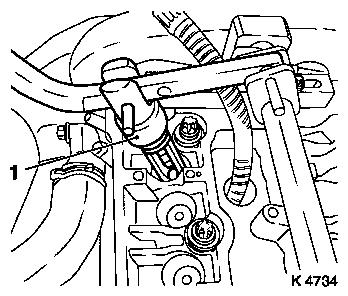

| 9. |

Remove 2x intake valve spring, cylinder 1

| • |

Carefully push valve springs downwards

| – |

With lever arm

Note: Removal head (1)

must be positioned vertically over the valve stem.

|

|

Important: Observe correct

assignment.

|

| • |

Take out valve cotters, valve discs, valve springs

Note: Do not use any

magnetic tools.

|

|

|

|

Install

Install

| 10. |

Renew 2x valve stem seals

| • |

Place 2x new valve stem seal on to valve stem

|

|

|

|

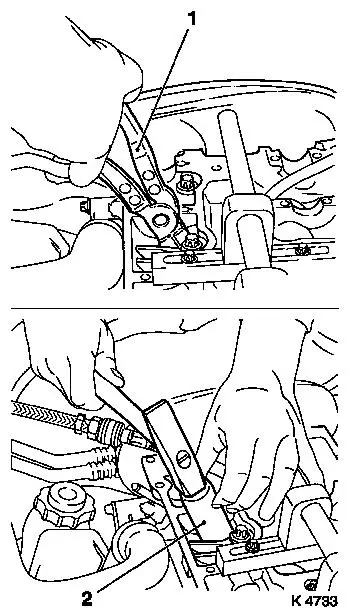

| 11. |

Install 2x intake valve spring, cylinder 1

| • |

Insert valve springs, valve disks

|

| • |

Insert valve cotters (1) into assembly head

| – |

Slide plastic clamping sleeve (2) in direction of lever arm

mount

|

Important: Insert valve cotters

with tapered end towards valve.

|

| – |

Push plastic clamping sleeve towards valve

|

|

| • |

Attach assembly head to lever arm

|

| • |

Carefully push valve springs downwards

Important: Assembly head must

stand vertically above valve stem. Valve cotters must engage

audibly.

|

| – |

with lever arm

|

|

|

|

|

Important: Do not make a 2nd

attempt without checking that both valve cotters are seated in the

assembly head. Check seat of valve cotters. Ensure pressure is

being applied.

|

| 12. |

Check installation position

|

| 13. |

Transfer lever arm

| • |

Insert lever arm

Note: Removal head must

point towards the exhaust side.

|

|

| 14. |

Remove 2x exhaust valve spring, cylinder 1

| • |

Carefully push valve springs downwards

| – |

With lever arm

Note: Dismantling head

must be positioned vertically over the valve stem

|

|

Important: Observe correct

assignment.

|

| • |

Take out valve cotters, valve discs, valve springs

Note: Do not use any

magnetic tools.

|

|

| 15. |

Renew 2x valve stem seals

| • |

Place 2x new valve stem seal on to valve stem

|

|

| 16. |

Install 2x exhaust valve spring, cylinder 1

| • |

Insert valve springs, valve disks

|

| • |

Insert valve cotters into assembly head

| – |

Push plastic clamping sleeve towards lever arm mounting

|

Important: Insert valve cotters

with tapered end towards valve.

|

| – |

Push plastic clamping sleeve towards valve

|

|

| • |

Attach assembly head to lever arm

|

| • |

Carefully push valve springs downwards

Important: Assembly head must

stand vertically above valve stem. Valve cotters must engage

audibly.

|

| – |

with lever arm

|

|

|

Important: Do not make a 2nd

attempt without checking that both valve cotters are seated in the

assembly head. Check seat of valve cotters. Ensure pressure is

being applied.

|

| 17. |

Check installation position

|

| 18. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of cylinder 1

|

| • |

Screw into spark plug thread, cylinder 4

|

| • |

Apply compressed air to cylinder 4

|

|

| 19. |

Transfer lever arm

| • |

Attach removal head

| – |

Insert pin

Note: Removal head must

point towards the exhaust side.

|

|

|

| 20. |

Remove 2x exhaust valve spring, cylinder 4

|

| 21. |

Renew 2x valve stem seals

|

| 22. |

Install 2x exhaust valve spring, cylinder 4

|

| 23. |

Check installation position

|

| 24. |

Transfer lever arm

| • |

Attach lever arm

Note: Removal head must

point towards the intake side.

|

|

| 25. |

Remove 2x intake valve spring, cylinder 4

|

| 26. |

Renew 2x valve stem seals

|

| 27. |

Install 2x intake valve spring, cylinder 4

|

| 28. |

Check installation position

|

| 29. |

Interrupt compressed air feed

|

| 31. |

Set cylinder 2 to TDC of combustion stroke

| • |

Turn crankshaft evenly (180°)

Note: Torsional

vibration damper auxiliary marking must be flush with timing case

cover marking.

|

|

| 32. |

Engage gear and put the handbrake on

Note: All the wheels

must be in contact with the ground

|

| 33. |

Transfer lever arm

| • |

Attach removal head

Note: Removal head must

point towards the intake side.

|

|

| 34. |

Transfer compressed air adapter

| • |

Unscrew from spark plug thread, cylinder 4

|

| • |

Screw into spark plug thread of cylinder 2

|

| • |

Apply compressed air to cylinder 2

|

|

| 35. |

Remove 2x intake valve spring, cylinder 2

|

| 36. |

Renew 2x valve stem seals

|

| 37. |

Install 2x intake valve spring, cylinder 2

|

| 38. |

Check installation position

|

| 39. |

Transfer lever arm

| • |

Attach lever arm

Note: Removal head must

point towards the exhaust side.

|

|

| 40. |

Remove 2x exhaust valve spring, cylinder 2

|

| 41. |

Renew 2x valve stem seals

|

| 42. |

Install 2x exhaust valve spring, cylinder 2

|

| 43. |

Check installation position

|

| 44. |

Transfer lever arm

| • |

Attach removal head

Note: Removal head must

point towards the exhaust side.

|

|

| 45. |

Transfer compressed air adapter

| • |

Unscrew from spark plug thread, cylinder 2

|

| • |

Screw into spark plug thread, cylinder 3

|

| • |

Apply compressed air to cylinder 3

|

|

| 46. |

Remove 2x exhaust valve spring, cylinder 3

|

| 47. |

Renew 2x valve stem seals

|

| 48. |

Install 2x exhaust valve spring, cylinder 3

|

| 49. |

Check installation position

|

| 50. |

Transfer lever arm

| • |

Attach lever arm

Note: Removal head must

point towards the intake side.

|

|

| 51. |

Remove 2x intake valve spring, cylinder 3

|

| 52. |

Renew 2x valve stem seals

|

| 53. |

Install 2x intake valve spring, cylinder 3

|

| 54. |

Check installation position

|

| 55. |

Detach automatic valve spring lever

|

| 56. |

Remove compressed air adapter

| • |

Interrupt compressed air feed

|

|

| 58. |

Adjust TDC of combustion stroke, cylinder 4

| • |

Turn crankshaft evenly (180°)

Note: Torsional

vibration damper TDC notch must be flush with timing case cover

marking.

|

|

| 59. |

Visually check components

| • |

Camshafts, camshaft bearing cap, hydraulic valve lifter,

cylinder head, spark plugs

|

|

| 60. |

Insert 8x roller cam follower, exhaust side

Important: Observe correct

assignment.

|

| • |

Lightly coat sliding surfaces with engine oil

|

|

| 61. |

Insert 8x roller cam follower, intake side

Important: Observe correct

assignment.

|

| • |

Lightly coat sliding surfaces with engine oil

|

|

| 62. |

Install 4x spark plug

| • |

Tighten using KM-194-E 25 Nm

|

|

|