|

Engine, Remove and Install

| 2. |

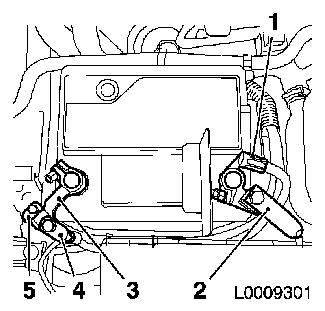

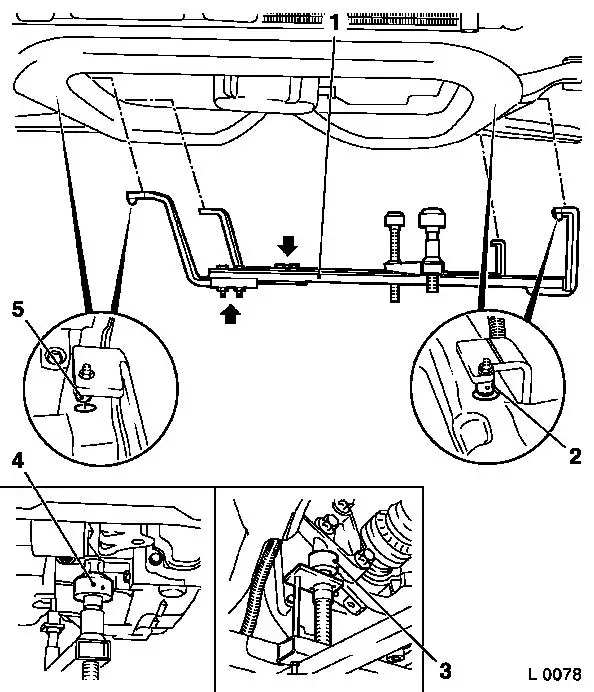

Detach earth cable

| • |

Detach earth cables (4) and (5) from earth terminal (3)

|

| • |

Detach earth connection from negative terminal

|

|

| 3. |

Detach positive cable

| • |

Detach positive cable (2) from positive terminal (1)

|

| • |

Detach positive connection from positive terminal

|

|

|

|

| 4. |

Empty climate control system

|

| 5. |

Remove lower driver's side cover

| • |

Release 2x retaining clips

|

|

| 6. |

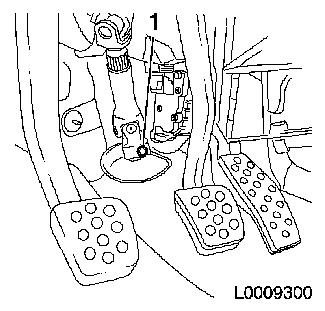

Detach steering column intermediate shaft

| • |

Set steering wheel in straight ahead position, remove ignition

key and engage steering lock

|

|

|

|

| 7. |

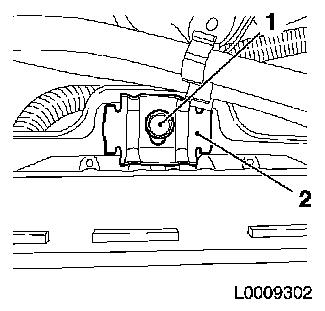

Remove battery

| • |

Detach positive connection from positive terminal

|

| • |

Remove battery bracket (2)

|

|

|

|

| 8. |

Disconnect charge pressure sensor wiring harness plug

|

| 9. |

Disconnect upper cooling module wiring harness

| • |

Disconnect wiring harness connector.

|

| • |

Unclip relay from bracket

|

|

| 10. |

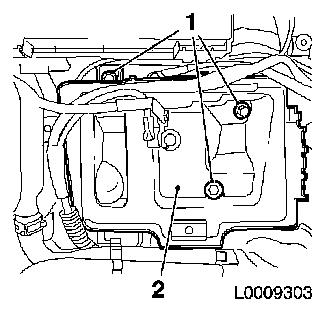

Remove battery support (2)

| • |

Detach wiring harness from battery support

|

|

|

|

| 11. |

Remove air cleaner housing with mass air flow sensor

| • |

Disconnect air mass flow meter wiring harness plug

|

| • |

Detach air intake hose from air intake pipe

|

| • |

Unscrew bolt

Note: The wiring

harness plug cannot be disconnected without first removing the mass

air flow sensor from the air cleaner housing

|

|

| 12. |

Detach brake servo vacuum line from intake manifold

| • |

Disconnect quick-release fitting

|

| • |

Unclip vacuum line from bracket

|

|

| 13. |

Remove air intake pipe

| • |

Remove engine vent hose from cylinder head cover

Note: Seal air intake

pipe to turbocharger

|

|

| 14. |

Place collecting basin underneath.

|

| 15. |

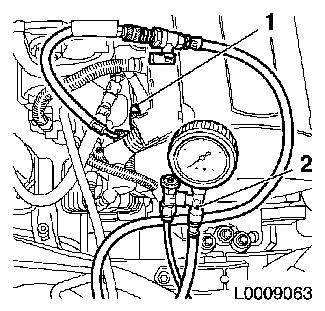

Relieve fuel pressure using KM-J-34730-91 at test connection

Note: Collect exiting

fuel in a suitable container - observe safety regulations and

national legislation.

|

|

|

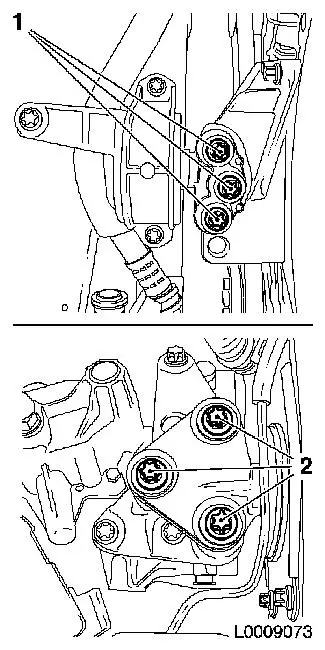

| 16. |

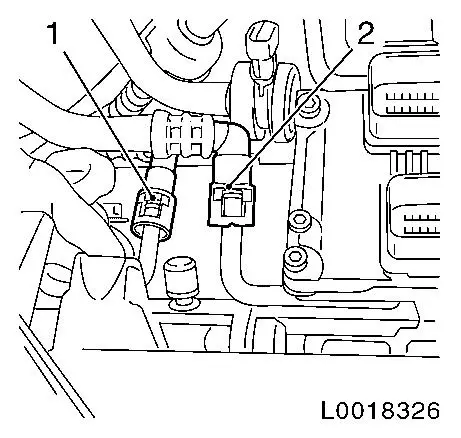

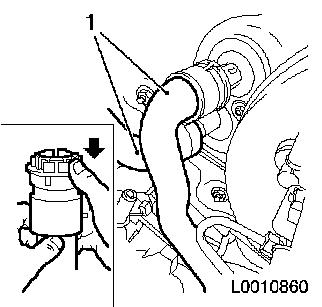

Detach fuel supply line (2)

| • |

Undo quick-release fitting with KM-796-A

|

|

| 17. |

Detach fuel return line (1)

| • |

Undo quick-release fitting with KM-796-A

|

|

|

|

| 18. |

Detach venting line of tank vent valve

| • |

Undo quick-release fitting with KM-796-A

|

|

| 19. |

Disconnect fuel vapour separator line

| • |

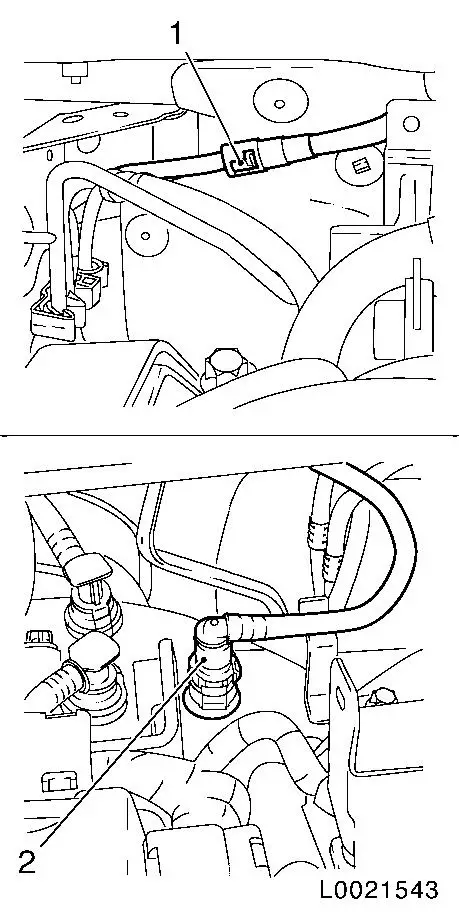

Undo quick-release fitting (1)

|

|

| 20. |

Detach brake servo vacuum line from intake manifold

| • |

Disconnect quick-release fitting (2)

|

|

|

|

| 22. |

Raise vehicle by half its height

|

| 23. |

Remove 2x front wheels

|

| 24. |

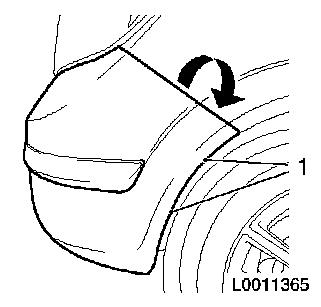

Remove front panelling (3)

| • |

Remove 5x body-bound rivets (2)

|

|

|

|

| 25. |

Place collecting basin underneath.

|

| 26. |

Detach high-pressure headlamp cleaning system hose from

reservoir

| • |

Disconnect quick-release fitting

Note: Escaping

fluid

|

|

| 27. |

Remove front panelling

Note: Use a second

person

Note: Push front

panelling upwards at side and pull out of bracket

| • |

Detach front panelling from bracket

|

| • |

Unclip outside temperature sensor

|

|

|

|

| 28. |

Remove engine splash guard (right-hand)

| • |

Remove 2x body-bound rivet

|

|

| 29. |

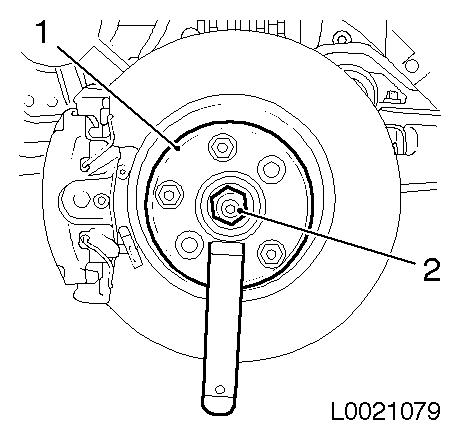

Detach 2x axle shafts from wheel hub

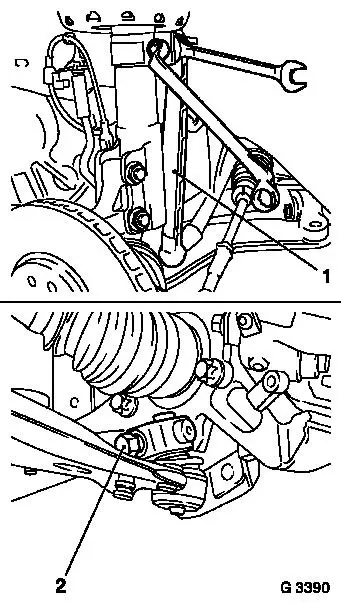

| • |

Unscrew 2x nuts (2) from axle shaft

| – |

Counterhold with KM-6610 (1) at front

wheel hub

|

|

|

|

|

| 30. |

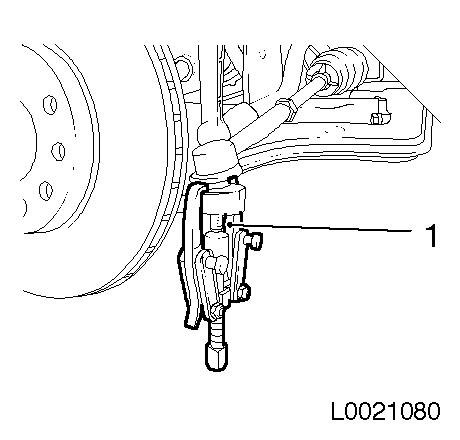

Undo tie rod end (6) from steering knuckle (5)

| • |

Attach CH-47658 (1)

| – |

Position CH-47658 (1) with suitable

sleeve (4)

Note: In order to

centre CH-47658 , CH-47658 must be used with the appropriate socket

wrench groove (3).

|

| – |

Fasten CH-47658 (1) to hexagonal

section (2)

|

|

| • |

Unscrew tie rod end nut

|

|

|

|

| 31. |

Press tie rod out of steering knuckle using KM-161-B (1) in conjunction with hook KM-161-2

|

|

|

| 32. |

Detach 2x swing arms (1) from spring strut support tube

| • |

Use open-ended wrench to hold against the flat surfaces

|

|

| 33. |

Detach guide joint from steering knuckle

| • |

Detach 2x screw connections

|

| • |

Expand steering knuckle with KM-915

(2)

|

| • |

Pull guide joint out of steering knuckle

|

|

| 34. |

Press axle shaft out of wheel hub

Note: Do not pull the

steering knuckle outwards when doing so. Use a wheel hub puller if

necessary.

|

|

|

| 35. |

Raise vehicle by half its height

|

| 36. |

Release left wheel housing inner panelling

| • |

Remove 3x body-bound rivets

|

|

| 37. |

Detach cooling module wiring harness (1)

| • |

Disconnect wiring harness connector.

|

|

|

|

| 38. |

Place collecting basin underneath.

|

| 39. |

Drain coolant

| • |

Unscrew coolant drain bolt

|

| • |

Screw in coolant drain bolt

|

|

| 40. |

Detach catalytic converter control's oxygen sensor wiring

harness

| • |

Disconnect wiring harness connector.

|

|

| 41. |

Remove front exhaust pipe

| • |

Detach front exhaust pipe (1) from catalytic converter

|

| • |

Detach front exhaust pipe from middle silencer

|

|

|

|

| 42. |

Remove right drive shaft from intermediate shaft

Note: Drive out with

soft metal drift

Note: Oil flows out.

Place collecting pan underneath and seal the openings with a

plug.

|

| 43. |

Carefully place the axle shaft down

Note: Do not lay it on

the boots.

|

| 44. |

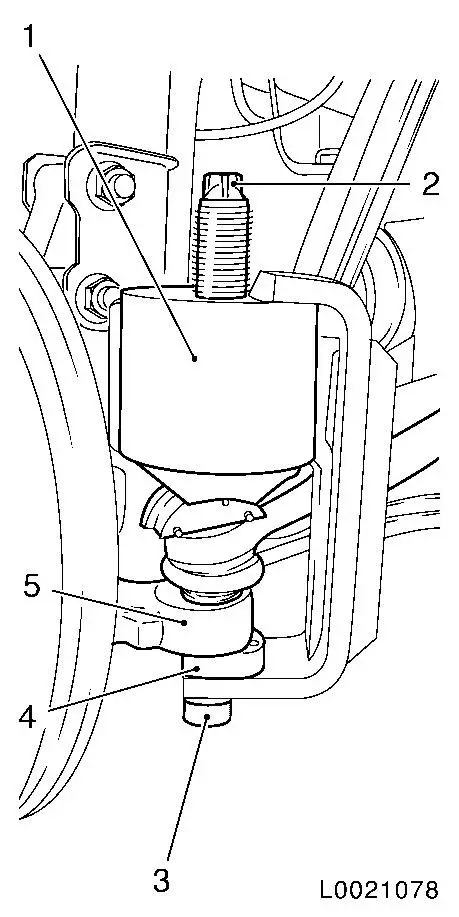

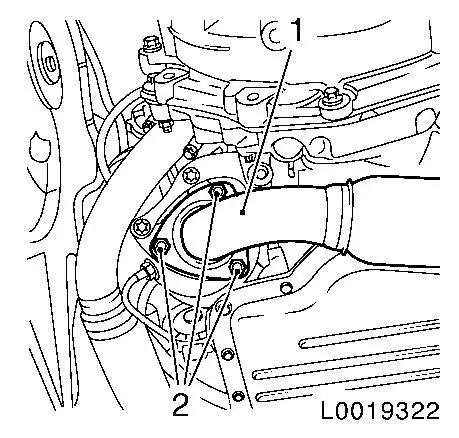

Insert KM-6173 (3)

| • |

Slacken 4x bolts (arrows) and hand-tighten

|

| • |

Align KM-6173 at front axle body

|

| • |

Wind up the support bearing (1)

| – |

Journal (2) must sit in mount at cylinder block

|

|

|

|

|

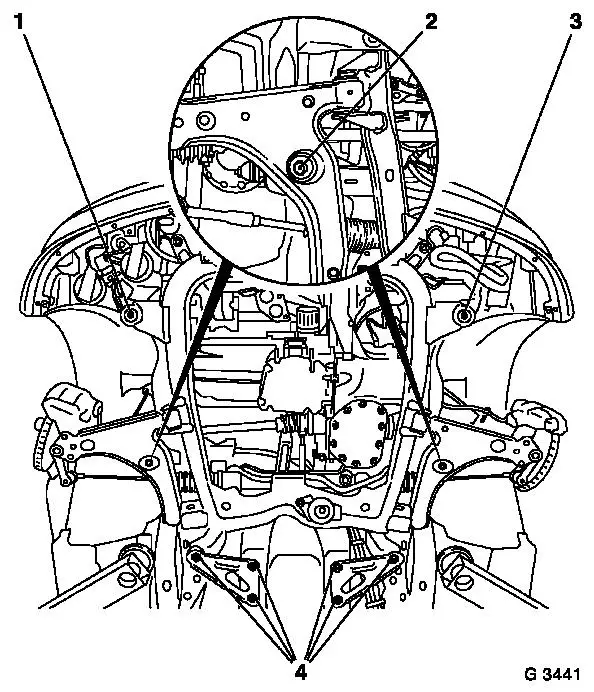

| 45. |

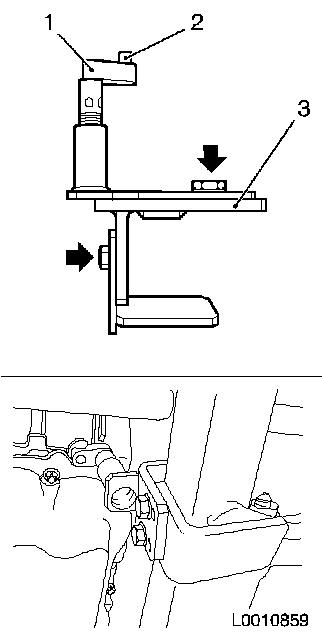

Attach KM-6001-A (1)

Note: Attaching KM-6001-A guarantees perfect alignment of the

drive unit with the front axle body

| • |

Slacken 3x bolts (arrows) in adjusting rails

|

| • |

Insert KM-6001-A

| – |

The journals (2) and (5) must sit in the guide holes of the

front axle body

|

|

| • |

Tighten 3x bolts in adjusting rails

|

| • |

Adjust support bearings, front (4) and rear (3)

| – |

Raise support bearings up to the stop on the guide journals

Note: The guide

journals must be seated free from play in the support bearings

|

|

|

|

|

| 46. |

Lower vehicle by its full height

|

| 47. |

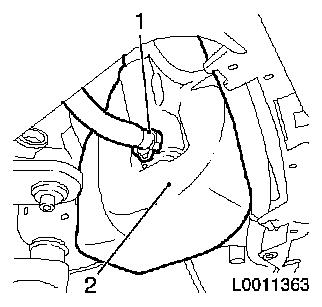

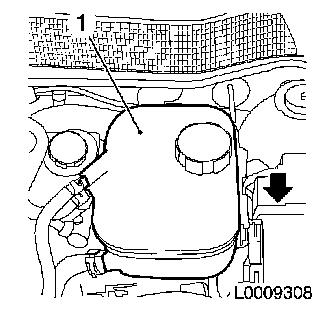

Remove coolant expansion tank (1)

| • |

Pull out of bracket in direction of arrow

|

|

|

|

| 48. |

Detach 2x shift cables

|

| 49. |

Disconnect the pressure line for central disengagement at the

clutch housing

| • |

Release clamp with screwdriver in direction of arrow and

remove

|

| • |

Lock retaining clamp

Note: Seal of line

ends

|

|

| 50. |

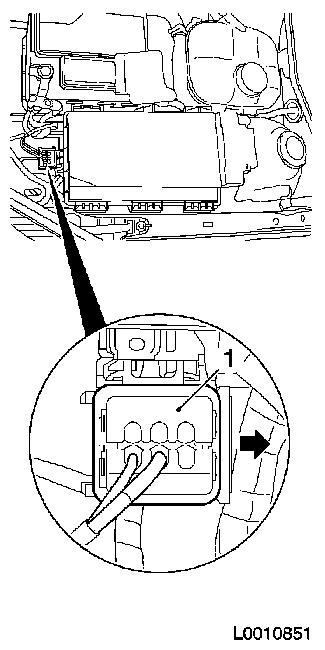

Disconnect steering wiring harness

| • |

Remove fuse carrier cover

|

| • |

Detach positive cable from fuse carrier

|

| • |

Disconnect wiring harness connector.

|

| • |

Expose wiring harness

| – |

Remove 2x from wiring harness bracket

|

|

|

| 51. |

Disconnect wiring harness plug of reversing lights

|

| 52. |

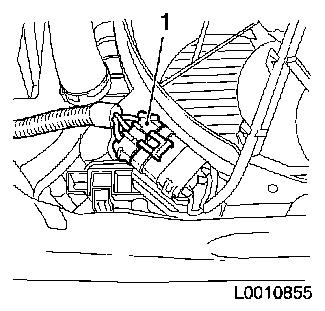

Disconnect wiring harness plug (1)

| • |

Release retainer in direction of arrow

|

|

|

|

| 53. |

Disconnect engine wiring harness

| • |

Unclip oxygen sensor wiring harness plug from bracket

|

| • |

Disconnect wiring harness connector.

|

| • |

Disconnect wiring harness plug of engine control unit

|

| • |

Unclip 2x retaining clips

|

|

| 54. |

Detach coolant hoses (1) from heater core

Note: Mark assignment

using coloured markings

| • |

Place collecting basin underneath.

|

| • |

Release 2x quick-release fittings in direction of arrow

|

|

|

|

| 55. |

Disconnect refrigerant line (low pressure side)

|

| 56. |

Detach refrigerant line from condenser

|

| 57. |

Detach right engine damping block from engine damping block

bracket

|

| 58. |

Detach left engine damping block from engine damping block

bracket

|

|

|

| 59. |

Raise vehicle by its full height

|

|

| 60. |

Attach KM-904 with KM-6390

| • |

Attach to hydraulic lifter

Note: Use hydraulic

jack that can be lowered to a height of at least 100 cm

|

| • |

Lower centring pins (1)

|

| • |

Place under front axle body, ensure there is no play

| – |

Centring pins (2) must engage in the relevant holes in the

front axle body

|

|

|

|

Important: It is not permissible

to disassemble the front axle body with an impulse or impact

screwdriver

|

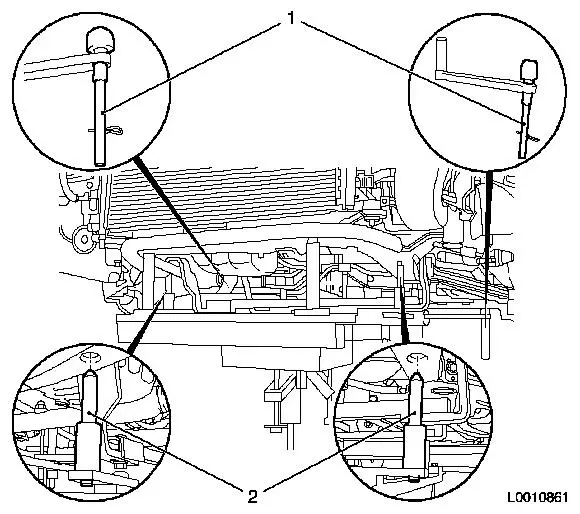

| 61. |

Remove front axle body

| • |

Unscrew 10x bolts (1, 2, 3, 4)

Note: Note different

bolt lengths

|

|

|

|

Important: Ensure that no

attached parts are damaged

|

| 62. |

Move out front axle body

Note: Use a second

person

|

Important: Ensure that no

attached parts are damaged

|

| 63. |

Move front axle body back in

Note: Use a second

person

|

Important: It is not permissible

to assemble the front axle body with an impulse or impact

screwdriver

|

| 64. |

Fit front axle body

| • |

Tighten 6x new bolt 90 Nm + 45° +

15°

|

|

| 65. |

Remove KM-904 with KM-6390

| • |

Detach KM-904 and KM-6100 from hydraulic jack

|

|

| 66. |

Lower vehicle by its full height

|

| 67. |

Attach right engine damping block to engine damping block

adapter

|

| 68. |

Attach left engine damping block to engine damping block

adapter

|

| 69. |

Attach refrigerant line to condenser

|

| 70. |

Connect refrigerant line (low pressure side)

|

Important: It is imperative to

adhere to the following assembly order

|

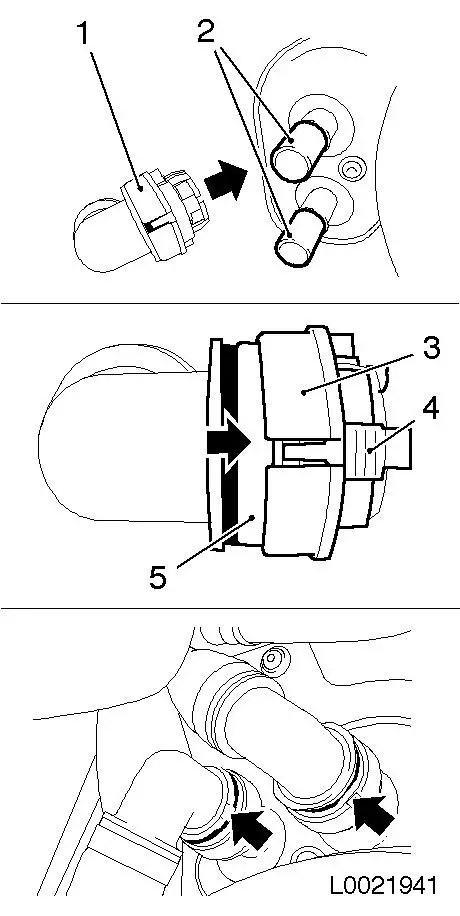

| 71. |

Attach cooling hoses to heater core

| • |

Fit 2x quick release fittings (1) onto heater core connection

port (2) as far as they will go

Note: Pay attention to

coloured markings

|

| • |

Slide the 2x quick-release fitting catches (3) in the direction

of the arrow all the way to the stop by simultaneously pressing the

release buttons (4)

| – |

The colour rings (5) must be visible

|

|

| • |

Check that quick release fittings are correctly seated and that

the colour rings (5) are visible

|

|

|

|

| 72. |

Connect engine wiring harness

| • |

Connect wiring harness plug of engine control unit

|

| • |

Clip in 2x retaining clips

|

| • |

Fix wiring harness plug

|

| • |

Clip oxygen sensor wiring harness plug to bracket

|

|

| 73. |

Fix wiring harness plug

Note: Front wiring

harness plug to fuse carrier

|

| 74. |

Connect wiring harness plug, reverse gear

|

| 75. |

Connect steering wiring harness

| • |

Clip in 2x wiring harness brackets

|

| • |

Attach positive cable to fuse carrier

|

| • |

Fix wiring harness plug

|

| • |

Install fuse carrier cover

|

|

| 76. |

Connect central release pressure line at clutch housing

| • |

Connect quick release fitting

|

|

| 77. |

Attach 2x shift cables

|

| 78. |

Raise vehicle by its full height

|

| 81. |

Install right drive shaft in intermediate shaft

|

| 82. |

Install front exhaust pipe

| • |

Attach front exhaust pipe with new gasket to catalytic

converter 20 Nm

|

| • |

Attach front exhaust pipe to middle silencer

|

|

| 83. |

Attach catalytic converter control oxygen sensor wiring

harness

| • |

Fix wiring harness plug

|

|

| 84. |

Lower vehicle by half its height

|

| 85. |

Attach cooling module wiring harness

| • |

Fix wiring harness plug

|

|

| 86. |

Fit left wheel housing inner panelling

| • |

Install 3x body-bound rivets

|

|

| 87. |

Install 2x axle shafts into wheel hub

| • |

Tighten 2x new nuts

| – |

Counterhold at wheel hub with KM-468-B

|

|

|

| 88. |

Attach 2x guide joints to steering knuckle

| • |

Tighten 2x new screwed joint 100

Nm

|

|

| 89. |

Attach 2x swing arms to spring strut support tube

| • |

Tighten 2x new nut 65 Nm

Note: Use spanner to

counterhold against flat surface

|

|

| 90. |

Attach 2x tie rods to steering knuckle

| • |

Tighten 2x new nut 50 Nm

|

|

| 91. |

Install right engine splash guard

| • |

Install 2x body-bound rivets

|

|

| 92. |

Insert front panelling

| • |

Second mechanic

Note: Slide side front

panelling into bracket

|

| • |

Attach front panelling to bracket

|

| • |

Clip in outside temperature sensor

|

|

| 93. |

Fit front panelling

| • |

Install 5x body-bound rivets

|

|

| 94. |

Attach high-pressure headlamp cleaning hose to reservoir

| • |

Connect quick release fitting

|

|

| 96. |

Lower vehicle by half its height

|

| 97. |

Fasten 2x front wheels 110 Nm

|

| 98. |

Install vacuum reservoir vacuum line to turbocharger

|

| 99. |

Attach venting line of tank vent valve

| • |

Connect quick release fitting

|

|

| 100. |

Attach fuel return line to fuel rail

|

| 101. |

Attach fuel supply line to fuel rail

|

| 102. |

Install air intake pipe.

Note: Install air

intake pipe connection to turbocharger

| • |

Attach engine vent hose to cylinder head cover

|

| • |

Fasten clamp; tighten bolt

|

|

| 103. |

Attach brake servo vacuum line to intake manifold

| • |

Connect quick release fitting

|

| • |

Clip vacuum line into bracket

|

|

| 104. |

Install air cleaner housing with mass air flow sensor

| • |

Insert the air cleaner housing

|

| • |

Attach air intake hose to air intake pipe

|

| • |

Connect mass air flow meter wiring harness plug

|

|

| 105. |

Attach brake bleeder unit to bleeder valve

| • |

Remove valve cap from connecting piece's bleeder valve

|

| • |

Attach MKM-6174-1 to bleeder

valve

|

|

| 106. |

Attach brake bleeder unit to brake fluid reservoir

| • |

Attach brake bleeder unit adapter to brake fluid reservoir

|

| • |

Attach MKM-6174-2 to brake bleeder

unit adapter

|

|

| 107. |

Bleed clutch actuation

| • |

Activate brake bleeder unit

|

| • |

Close bleeder valve hand-tight

| – |

Deactivate brake bleeder unit

|

|

|

| 108. |

Detach brake bleeder unit from brake fluid reservoir

| • |

Detach brake bleeder unit adapter from brake fluid

reservoir

|

| • |

Fit brake fluid reservoir cover

|

|

| 109. |

Bleed transmission housing pressure line for central

disengagement

Note: Second

mechanic

|

| 110. |

Detach brake bleeder unit from bleeder valve

|

| 111. |

Check and correct brake fluid level

|

| 112. |

Install battery holder

| • |

Attach wiring harness to battery support

|

|

| 113. |

Insert coolant expansion tank in bracket

|

| 114. |

Connect upper cooling module wiring harness

| • |

Fix wiring harness plug

|

| • |

Clip relay into bracket

|

|

| 115. |

Connect charge pressure sensor wiring harness plug

|

| 116. |

Install battery

| • |

Install battery bracket

|

| • |

Attach positive connection to positive terminal

|

|

| 117. |

Attach positive cable to positive terminal

|

| 118. |

Connect battery

| • |

Attach ground connection to ground terminal

|

|

| 119. |

Attach earth cable to earth terminal

|

| 120. |

Fill with coolant and correct coolant level

|

| 121. |

Top up climate control system

|

| 123. |

Attach steering intermediate shaft

| • |

Coat bolts with bolt locking compound.

|

|

| 124. |

Install lower driver's side cover

| • |

Lock 2x retaining clips

|

|

| 125. |

Programme transient memory

|

|