|

Check compression

Remove Remove

Important: Cleanliness is

absolutely essential when working on the fuel system because even

small dirt particles can lead to disruption to engine operation or

the fuel system. Open fuel systems must be sealed with appropriate

sealing plugs from the kit (45 06 154). Sealing plugs are only

designed to be used once.

|

| 1. |

Open bonnet

|

Important: On vehicles with ESP -

the steering angle sensor loses its basic adjustment each time the

battery is disconnected. It must be recalibrated.

|

| 2. |

Disconnect battery

|

Warning: When working on the common

rail system, wait one minute after switching off the engine. The

system relieves the pressure itself.

|

| 3. |

Waiting time for pressure relief

|

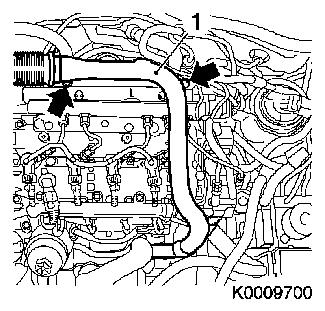

| 4. |

Remove charge air pipe (1)

| • |

Unscrew 2x bolt (arrows)

|

|

|

|

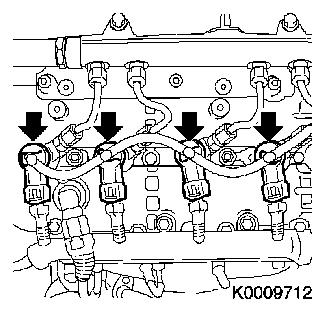

| 5. |

Detach outer oil leak line

| • |

Remove 4 retaining clamps (arrows)

|

|

|

|

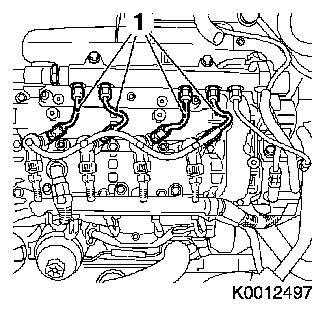

| 6. |

Detach 4 high-pressure lines (1)

|

|

|

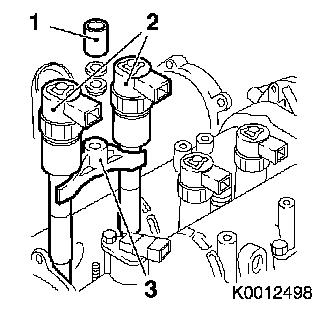

| 7. |

Disconnect 4 injector wiring harness plugs

| • |

Release wiring harness plug

|

|

| 8. |

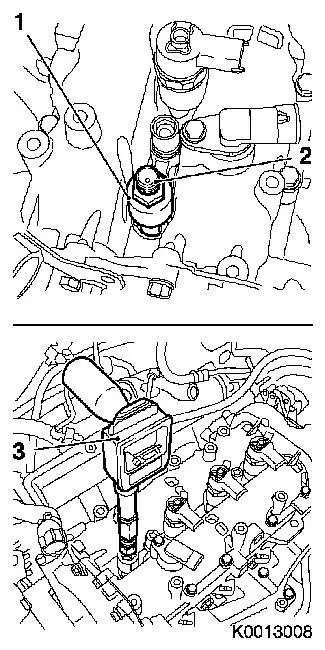

Release 2x injector bracket (3)

|

| 9. |

Remove 4x injector (2)

Note: The injectors can

only be removed in pairs (cylinder 1 + 2 or cylinder 3 + 4)

|

|

|

| 10. |

Connect compression recorder

| • |

Use EN-46782 (1) in conjunction with

EN-46783 (2)

Note: The adapter for

checking compression can only be installed in conjunction with the

injectors in pairs (cylinder 1 + 2 or cylinder 3 + 4).

|

| • |

Connect compression recorder (3)

| – |

Measurement range 1000 to 4000 kPa (10 to 40 bar)

Note: Follow

manufacturer's instructions.

|

|

|

|

|

| 11. |

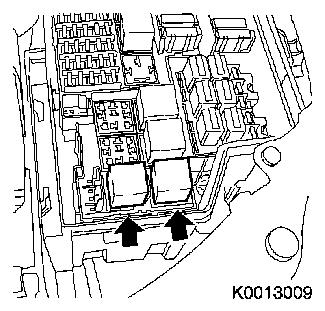

Remove fuel pump relay

| • |

Remove 2x relay (arrows)

|

|

|

|

| 13. |

Calibrate steering angle sensor

| • |

Turn on ignition

Note: Turn the steering

wheel once from the right stop to left stop.

|

|

| 14. |

Check compression

Note: Second person

required

| • |

Start engine for approx. 4 seconds

Note: Engine speed at

least 200 rpm

|

| • |

Disconnect compression recorder

|

| • |

Detach EN-46782 , EN-46783 carefully

|

|

| 16. |

Compare compression values

| • |

Maximum permissible pressure difference: 150 kPa (1.5 bar).

|

|

| 17. |

Disconnect compression recorder

| • |

Remove EN-46782 , EN-46783

|

|

Install

Install

| 19. |

Install fuel pump relay

|

| 22. |

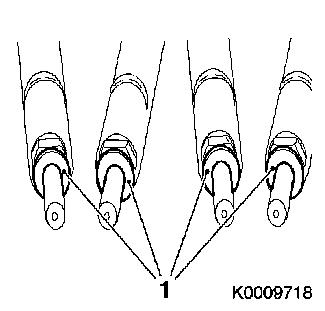

Install 4 injectors

| • |

Replace 4 injector seal rings (1)

|

|

|

|

| 23. |

Fasten 2 injector brackets

|

| 24. |

Attach outer oil leak line

| • |

Attach 4 retaining clamps

|

|

| 25. |

Connect 4 injector wiring harness plugs

| • |

Lock wiring harness plug

|

|

| 26. |

Attach 4 high-pressure lines

| • |

Tighten 4 union nuts (M14) 28 Nm

|

| • |

Tighten 4 union nuts (M12) 24 Nm

|

|

| 27. |

Install charge air pipe

|

| 29. |

Check the fuel system for leaks

Important: Wear protective

glasses and gloves.

|

| • |

Start engine.

Note: Check the fuel

system for escaping fuel.

|

|

| 30. |

Program volatile memory

|

|