|

Main Shaft, Disassemble and Assemble (F17+)

Note: Transmission

remains installed.

Remove Remove

|

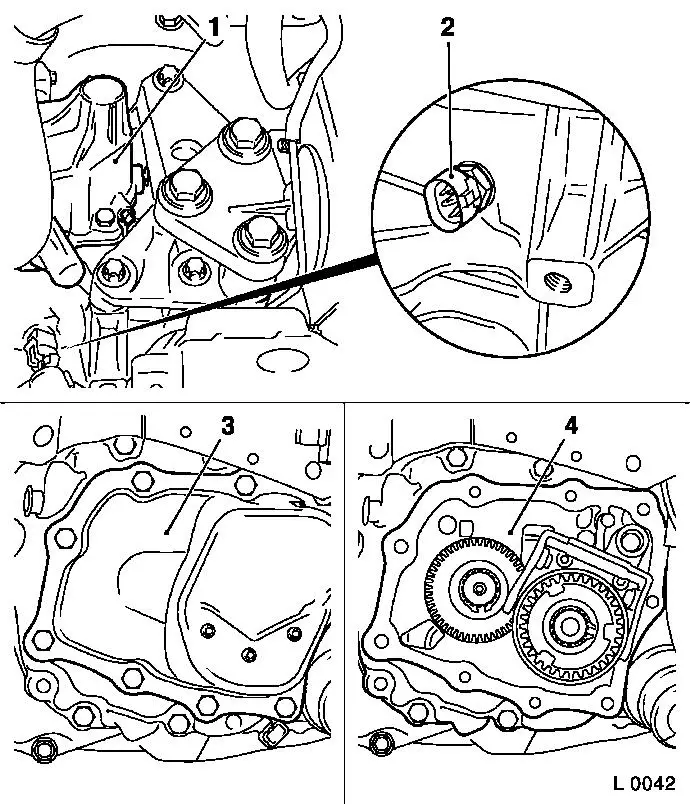

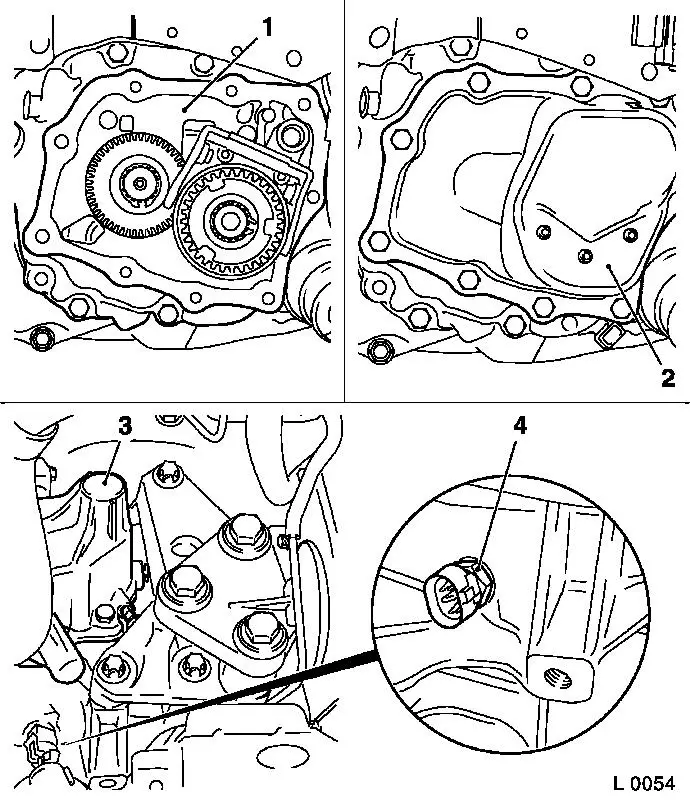

| 1. |

Remove shift mechanism cover (1)

|

| 2. |

Remove reversing lamp switch (2)

| • |

Disconnect wiring harness plug for reversing lamp switch

|

| • |

Unscrew reversing lamp switch

|

|

| 3. |

Remove end shield cover (3)

|

|

|

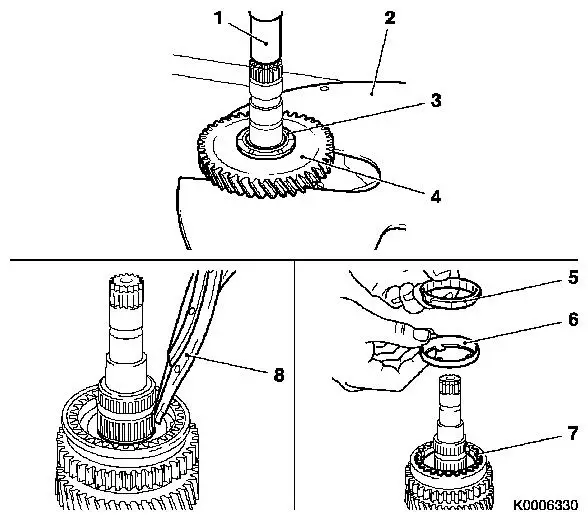

| 6. |

Remove 1st gear gearwheel

| • |

Push 1st gear gearwheel (4) off main shaft with KM-307-B (2) and KM-736

(1)

|

| • |

Remove gear wheel and pressure piece (3)

|

|

| 7. |

Remove 1st gear gearwheel synchro ring

| • |

Remove needle bearing, inner synchro ring (5), intermediate

ring (6) and outer synchro ring (7)

|

|

| 8. |

Remove synchro body retainer

| • |

Remove 1st/2nd gear synchro body retainer with KM-396 (8)

|

|

|

|

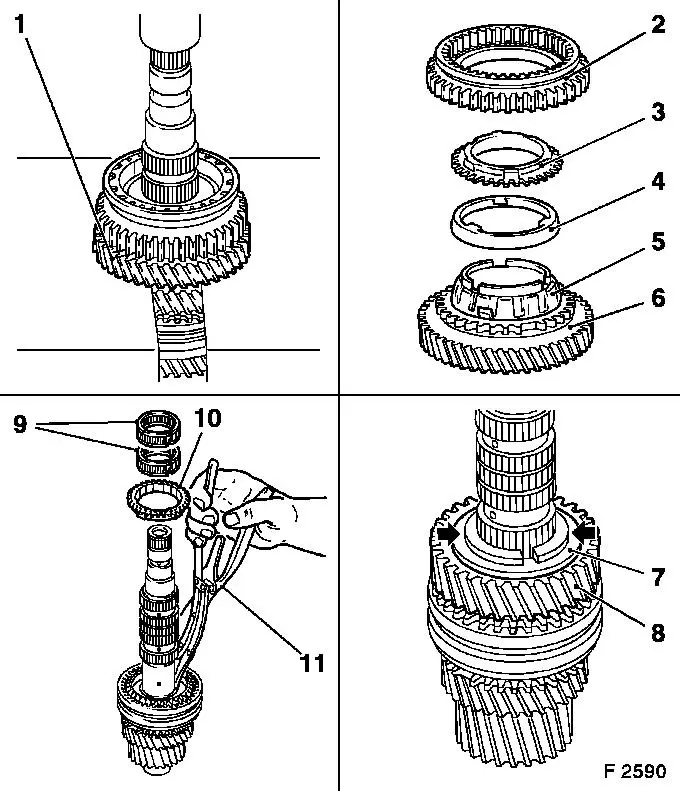

| 9. |

Remove 2ndgear gearwheel

| • |

Push 1st/2nd gear synchromesh body assembly and 2nd gear

gearwheel (1) off main shaft with KM-307-B and KM-736

|

| • |

Remove 1st/2nd gear shift sleeve (2), outer synchroniser ring

(3), intermediate ring (4) and inner synchroniser ring (5) from 2nd

gear gearwheel (6) and needle bearing

|

|

| 10. |

Remove pressure piece halves (arrows)

| • |

Remove pressure piece halves

|

|

| 11. |

Remove 3rd gear gearwheel (8)

|

| 12. |

Remove 3rd/4th gear synchro body retainer

| • |

Remove 2x slotted needle bearing (9)

|

| • |

Remove 3rd gear synchro ring (10)

|

| • |

Remove 3rd/4th gear synchro body retainer with KM-396 (11)

|

| • |

Remove spacer from synchro body

|

|

|

|

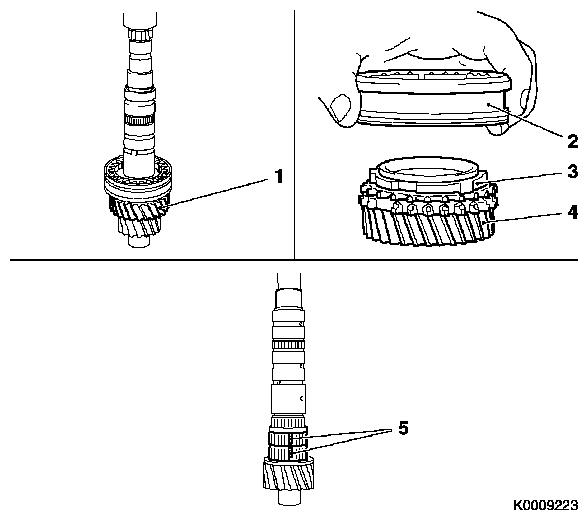

| 13. |

Detach 4th gear gearwheel

| • |

Press of 4th gear gearwheel (4) and synchromesh body with KM-307-B

|

| • |

Take 3rd/4th gear synchro body (2) and 4th gear synchro ring

(3) off 4th gear gearwheel

|

|

| 14. |

Remove needle bearing (5)

| • |

Remove 2x slotted needle bearings from main shaft

Note: Open needle

bearings.

|

|

|

Install

Install

Important: If gear wheels are

damaged, always inspect the wheels on the gear cluster and replace

this if necessary

|

| 16. |

Inspect parts

| • |

Check all parts for wear, damage and signs of scuffing -

replace if necessary

|

|

Important: Coat the bearing,

running or seating surfaces of rotating parts and surfaces under

pressure with transmission fluid. If a synchro body assembly is

completely dismantled, observe the following procedure for

assembly.

|

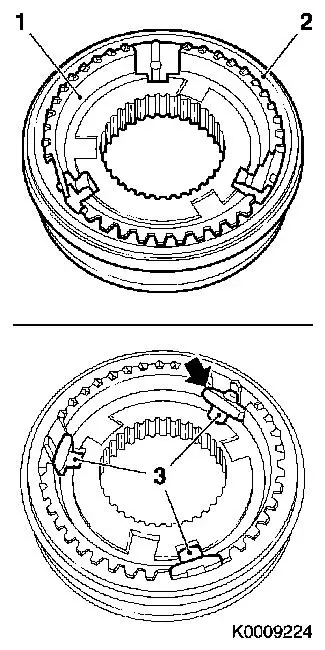

| 17. |

Assemble synchro body

| • |

Insert synchromesh body (1) into shifter collar (2)

|

| • |

Insert 3 thrust pieces (3)

Note: Attach bevel and

then press into synchromesh body assembly.

|

|

|

|

|

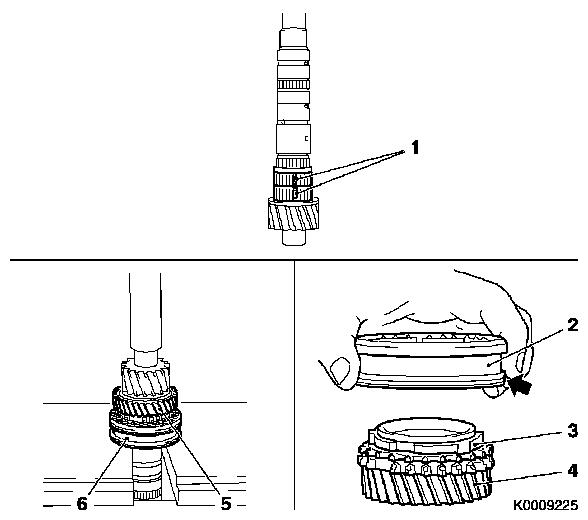

| 18. |

Fit needle bearing (1)

| • |

Set 2 slotted needle bearings on main shaft and clip

together

|

|

| 19. |

Attach 3rd/4th gear synchro body assembly

Important: Lugs on synchro ring

must be flush with grooves on synchro body

|

| • |

Position 4th gear synchroniser ring (3) and synchromesh body

assembly (2) on 4th gear gearwheel (4)

Note: Groove on sliding

sleeve (arrow) points to 4th gear gearwheel.

|

| • |

Press synchromesh body assembly (6) and 4th gear gearwheel (5)

onto main shaft

|

|

|

|

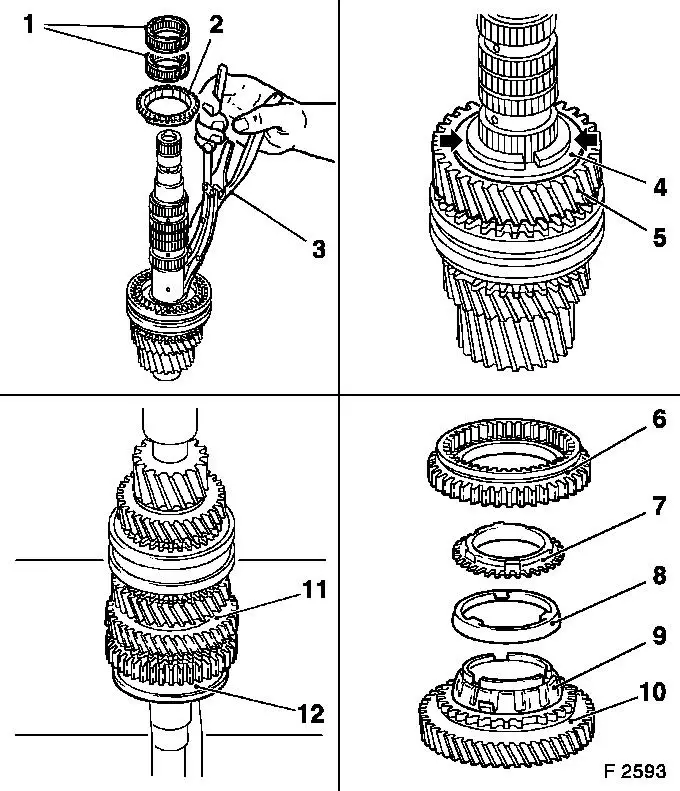

| 20. |

Attach 3rd gear gearwheel

| • |

Place spacer on synchro body

|

| • |

Fit new retainer with KM-396 (3)

Note: Retainer must be

correctly seated in groove

|

| • |

Place 3rd gear synchro ring (2) on synchro body assembly

|

| • |

Attach 2x slotted needle bearings (1) to main shaft

|

| • |

Place 3rd gear gearwheel (5) on main shaft

|

| • |

Fit both thrust washer halves (arrows) and retaining ring (4)

with grease

|

|

| 21. |

Attach1st/2nd gear synchro body assembly

Important: The lugs on the

synchroniser rings must align with the grooves on the synchromesh

body and the gearwheel.

|

| • |

Set needle bearing on main shaft

|

| • |

Place 1st/2nd gear synchro body assembly (6), with inner

synchro ring (9), intermediate ring (8) and outer synchro ring (7)

on 2nd gear gearwheel (10)

|

| • |

Push 1st/2nd gear synchro body assembly (12) and 2nd gear

gearwheel (11) onto main shaft

|

|

|

|

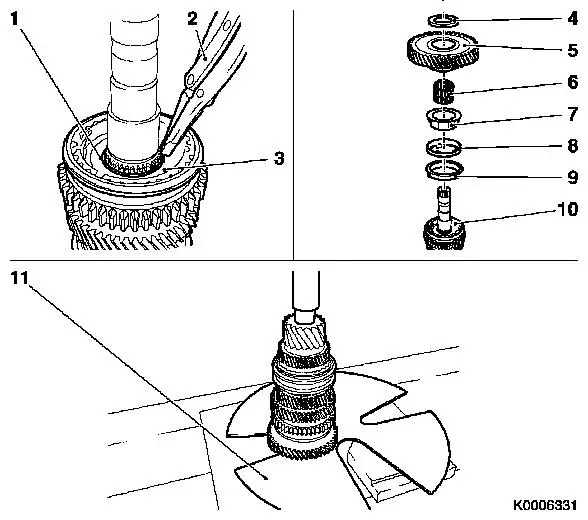

| 22. |

Secure 1st/2nd gear synchro body assembly (3)

| • |

Insert new retainer (1) with KM-396

(2)

Note: Retainer must be

correctly seated in groove

|

|

| 23. |

Attach 1st gear gearwheel (5)

| • |

Place slotted needle bearings (6) on main shaft

|

Important: The lugs on the

synchroniser rings must align with the grooves on the synchromesh

body and the gearwheel.

|

| • |

Place 1st gear gearwheel with inner synchro ring (9),

intermediate ring (8) and outer synchro ring (7) on 1st/2nd gear

synchro body assembly (10)

|

|

| 24. |

Attach 1st gear pressure piece (4)

| • |

Press pressure piece to main shaft with KM-307-B (11)

|

|

|

| 25. |

Visually inspect main shaft

| • |

All gear wheels must rotate freely

|

|

|

| 27. |

Install end shield (1)

Note: Observe the

magnet

|

| 28. |

Install end shield cover (2)

|

| 29. |

Install gearshift cover (3)

|

| 30. |

Transmission Fluid Level, Check and Correct

|

| 31. |

Install reversing lamp switch (4)

| • |

insert with new seal ring

|

| • |

Tighten reversing lamp switch 20

Nm

|

| • |

Connect wiring harness plug

|

|

| 32. |

Check ease of gear shifting

|

|

|