-

‒ →

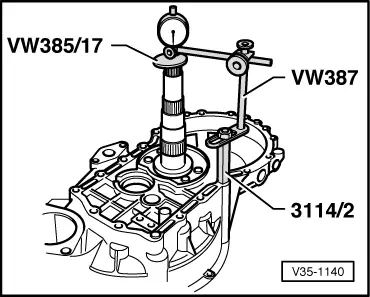

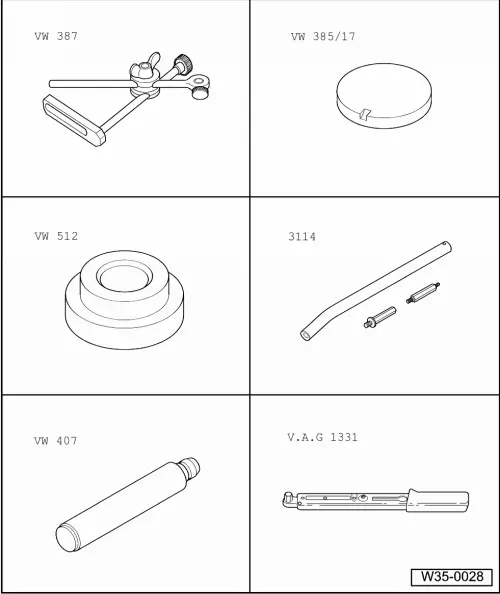

Mount dial gauge (3 mm measuring range) and set to "0" with 1 mm preload.

-

‒ Move output shaft up and down and note dial gauge reading (example: 0.30 mm).

Determining thickness of shim

The specified bearing preload is obtained by adding

a constant preload figure of (0.20 mm)

to the reading obtained (0.30 mm)

and the thickness of the shim installed (0.65 mm).

Example:

|

Shim installed

|

0.65 mm

|

|

+ Reading

|

0.30 mm

|

|

+ Preload (constant)

|

0.20 mm

|

|

Thickness of shim

|

1.15 mm

|

-

‒ Remove output shaft and pull out small taper roller bearing outer race => Page 35-38

The following adjustment shims are available:

|

|

|---|

|

Size (mm)

|

Part No.

|

|

0.65

0.70

|

020 311 391 P

020 311 391 Q

|

|

0.75

0.80

0.85

|

020 311 391

020 311 391 A

020 311 391 B

|

|

0.90

0.95

1.00

|

020 311 391 C

020 311 391 D

020 311 391 E

|

|

1.05

1.10

1.15

|

020 311 391 F

020 311 391 G

020 311 391 H

|

|

1.20

1.25

1.30

|

020 311 391 J

020 311 391 K

020 311 391 L

|

|

1.35

1.40

|

020 311 391 M

020 311 391 N

|

Varying tolerances make it possible to obtain the exact shim thickness required.

-

‒ Press in small taper roller bearing outer race together with the correct shim (in example 1.15 mm) (

) and install output shaft. Tighten bearing support nuts in clutch housing to 25 Nm and then turn 90° further.

|