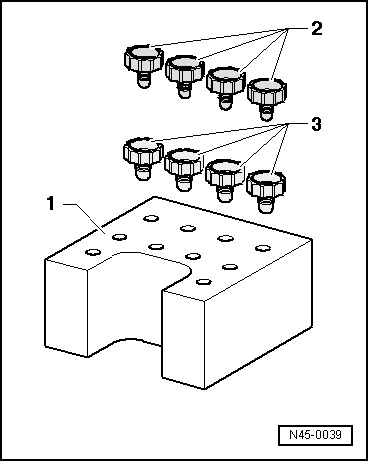

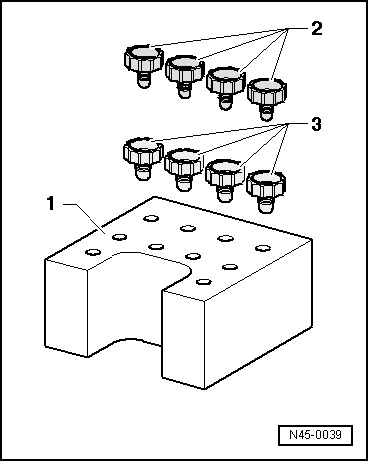

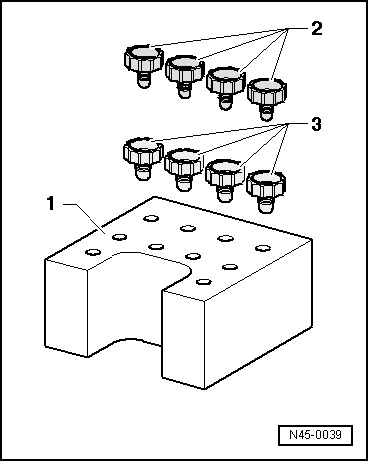

| Sealing plugs from repair kit, part number 1 H0 698 311 A |

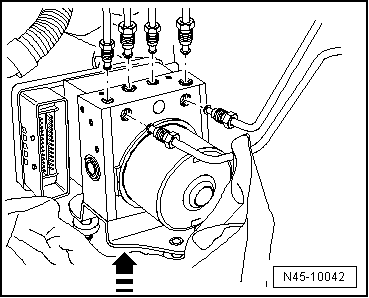

| The transport protection for the contact pins must always be placed on the hydraulic unit after the control unit has been disconnected from the hydraulic unit. |

| No warranty can be assumed for hydraulic units without transport protection. |

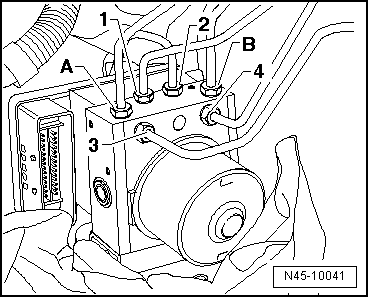

| 1 - | Transport protection for contact pins (foam) |

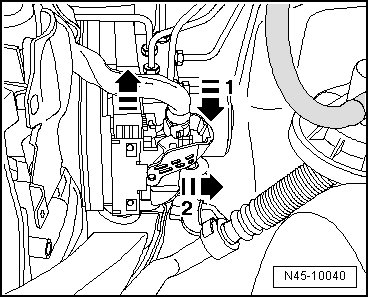

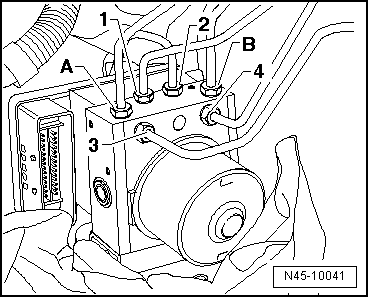

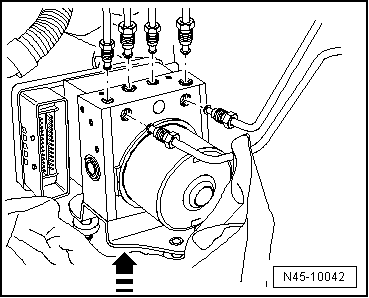

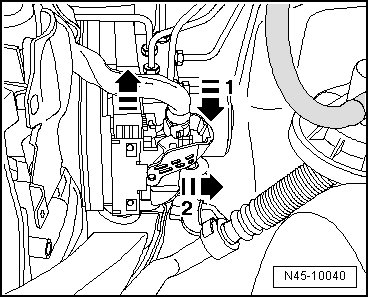

| The control unit is bolted to the hydraulic unit and is located on right in the engine compartment. |

WARNING | Do not bend the brake lines in the area of the hydraulic unit! |

|

| –

| Read out and note the existing control unit code. |

| –

| Note or request radio code on vehicles with coded radio if necessary. |

| –

| Remove engine cover panel. |

| Additional work on following engines: |

| –

| Pull hose off non-return valve. |

| –

| Clamp off hose from coolant expansion tank and pull it off. |

| Diesel engine with or without diesel particulate filter: |

| Diesel engines with diesel particulate filter: |

| –

| Unscrew exhaust gas pressure sensor 1 -G450-, separate electrical connectors, unscrew and lower diesel particulate filter → Rep. gr.26. |

| Continuation for all models: |

|

|

|