|

→

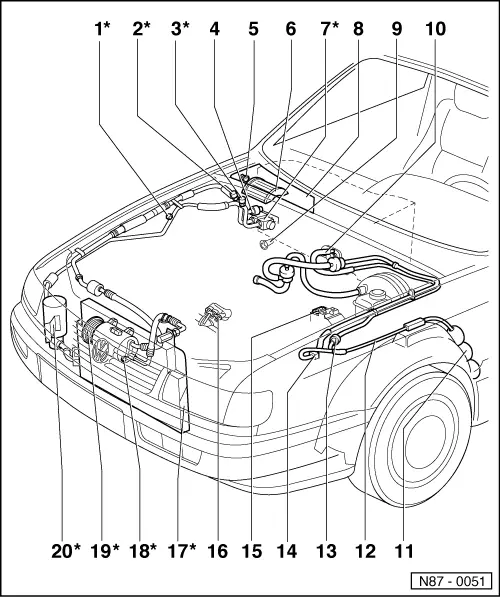

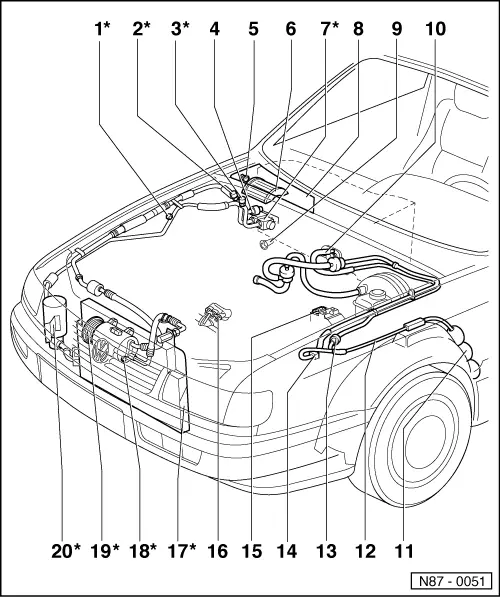

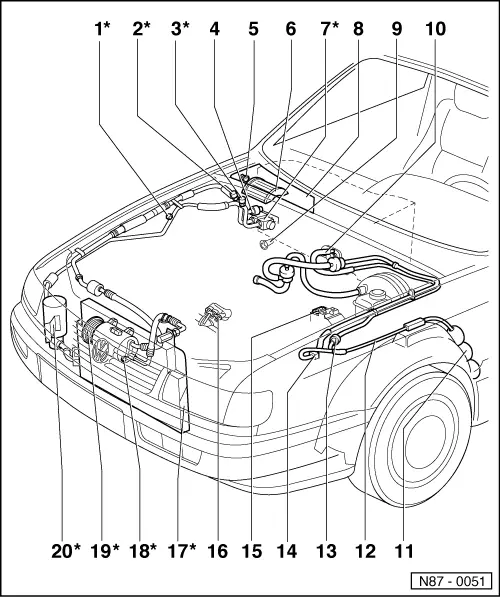

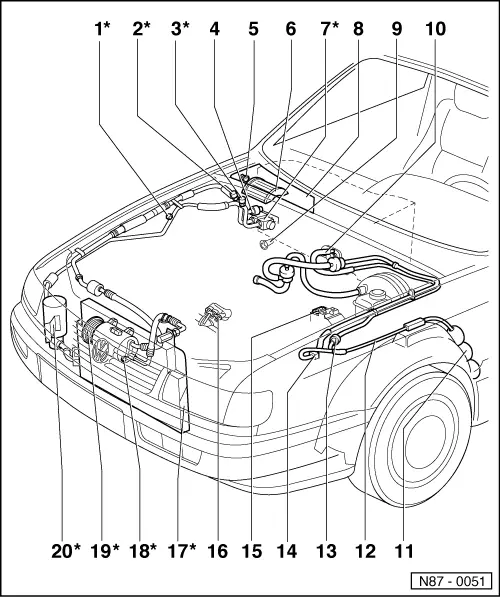

Fig.2

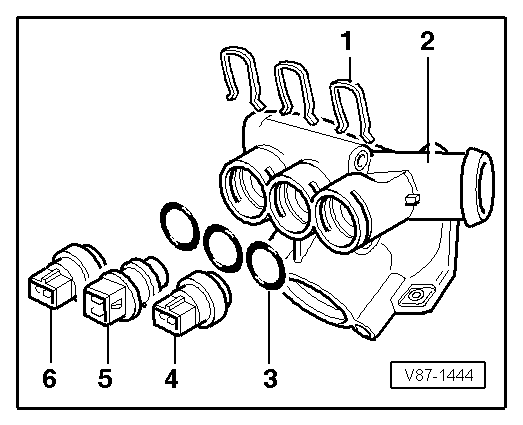

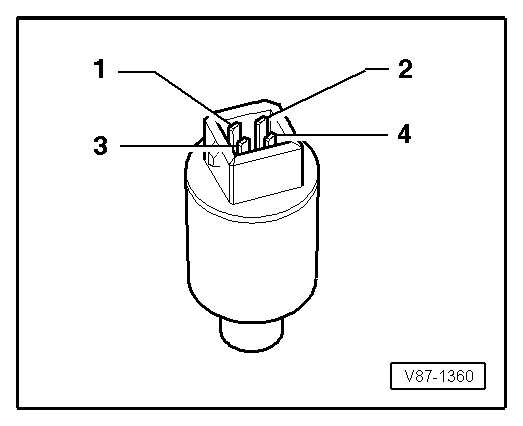

Checking air conditioner pressure switch -F129-

-

◆ Visual check: Ensure that O-ring (colour: red) 10.8 mm x 1.8 mm is seated in groove

Switch part between contacts -T4a/1- and -T4a/2 of connector housing switches magnetic coupling -N25- off when refrigerant circuit insufficiently filled or pressure too high.

-

‒ Opens below 1.2 bar and closes again above 2.4 bar (switching threshold)

-

‒ Opens above 32 bar and closes again below 24 bar (switching threshold)

-

‒ Briefly bridge circuit between chambers 1 and 2 with engine running. If the magnetic coupling -N25- switches on, the refrigerant system is empty. Take vehicle to specialist service workshop.

Switch part between contacts -T4a/3- and -T4a/4- of connector housing switches the coolant fan -V7- to second speed if the pressure in the refrigerant circuit increases.

-

‒ Closes above 16 bar and opens below 12.5 bar (switching threshold)

|