| t

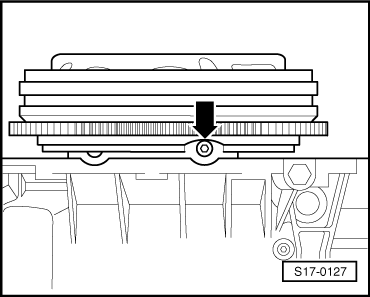

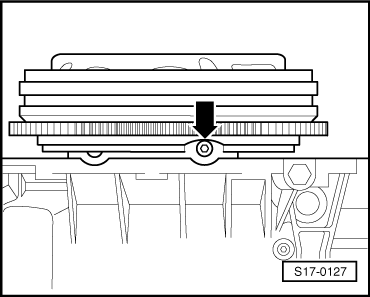

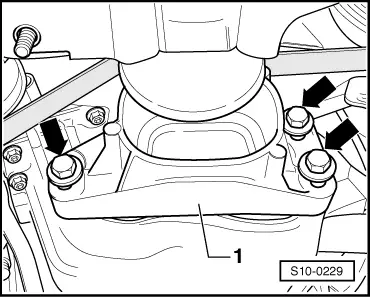

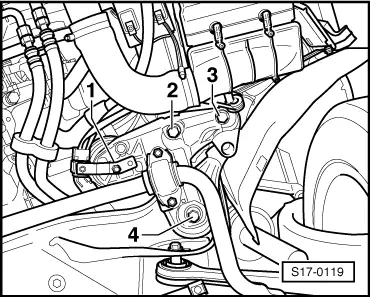

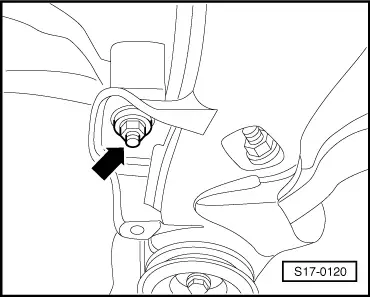

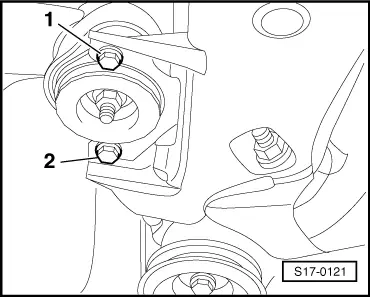

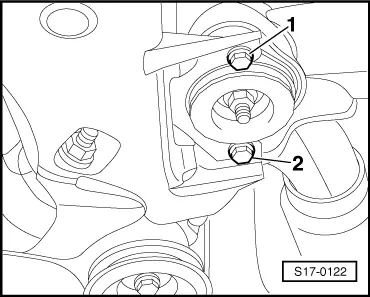

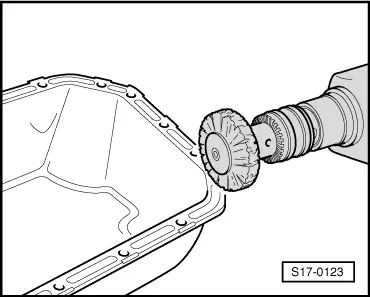

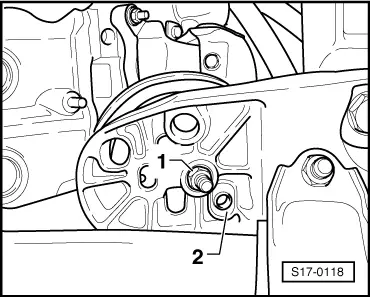

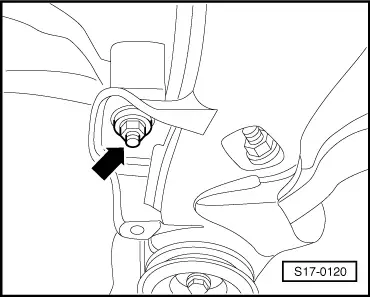

| The two rear inner oil pan screws are accessible through the recess -arrow- on the flywheel, turn the flywheel appropriately to allow this. |

| –

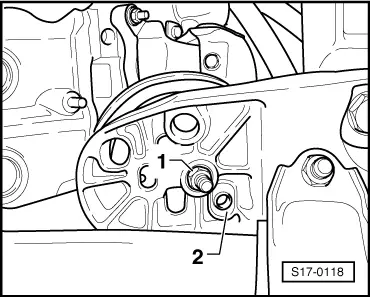

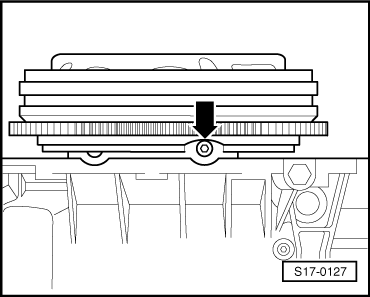

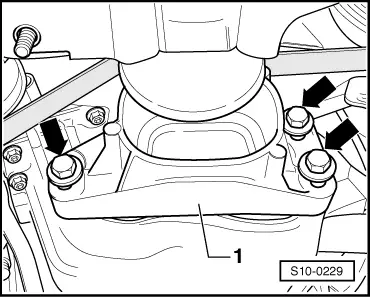

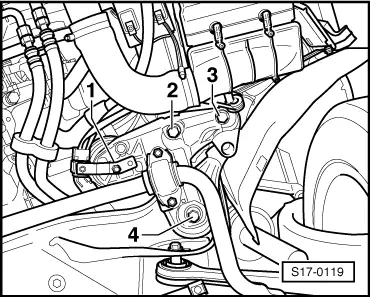

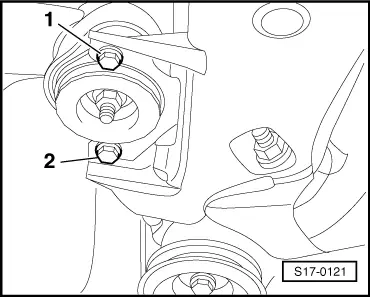

| Remove oil pan. If necessary release remove the oil pan by applying slight blows with a rubber-headed hammer. |

| –

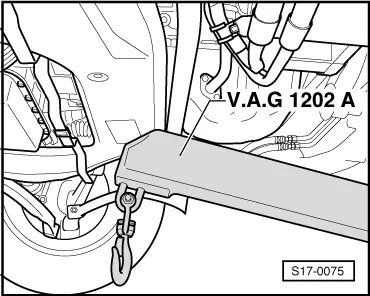

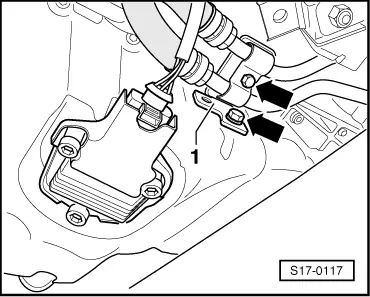

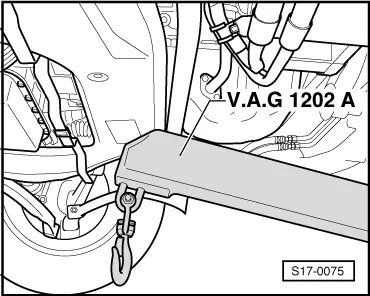

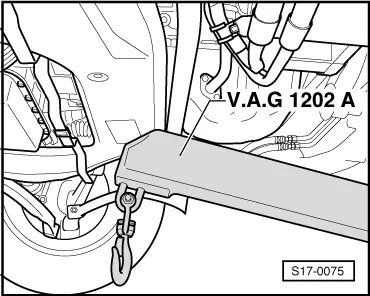

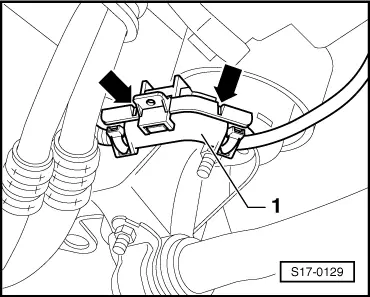

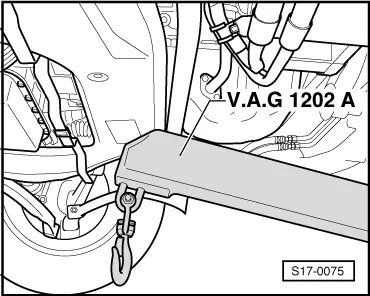

| In order to be able to swing the oil pan over the assembly carrier, swing the oil pan at the rear to the left and press the assembly carrier downwards somewhat on the left-hand side. |

| –

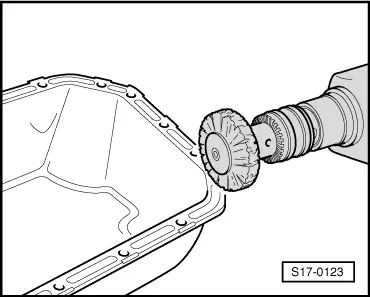

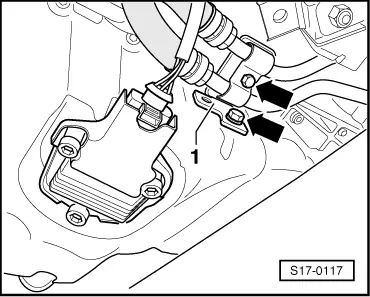

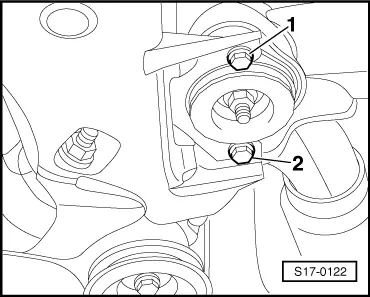

| Use a flat scraper to remove sealant residues on the cylinder block. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note