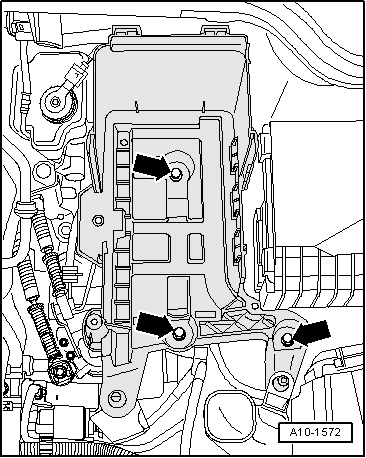

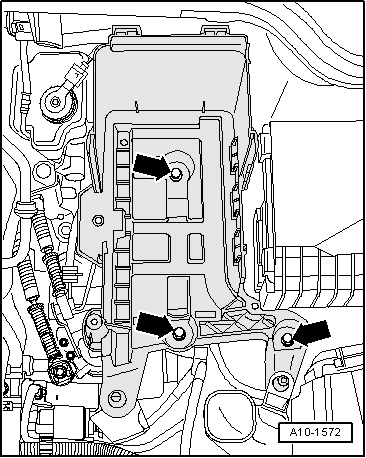

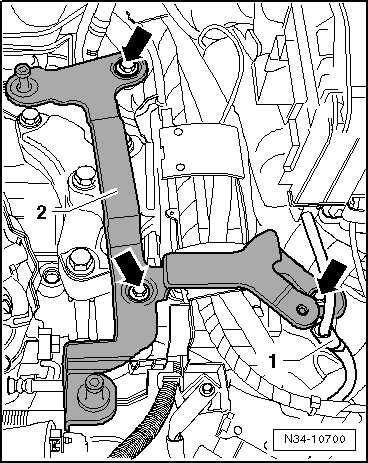

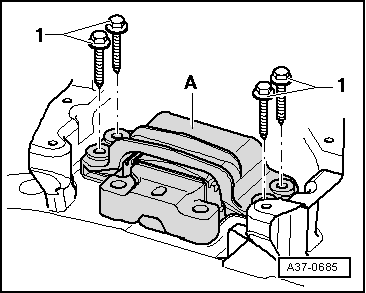

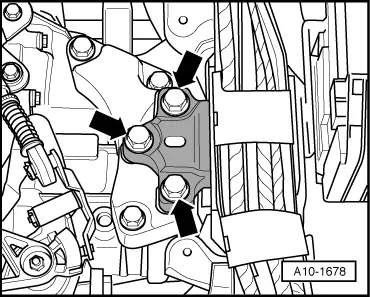

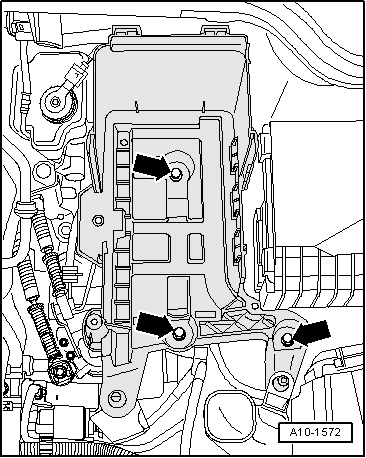

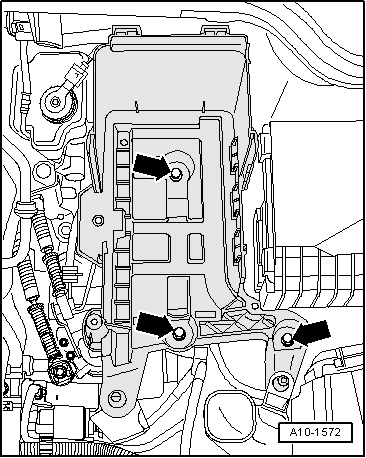

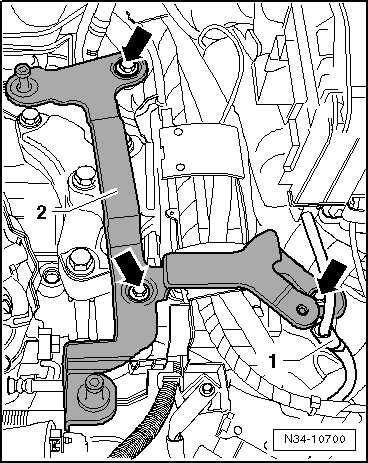

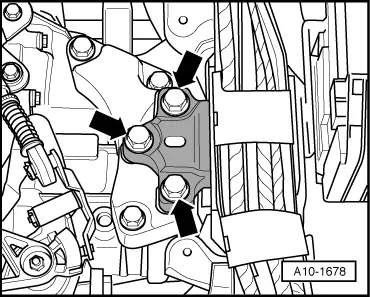

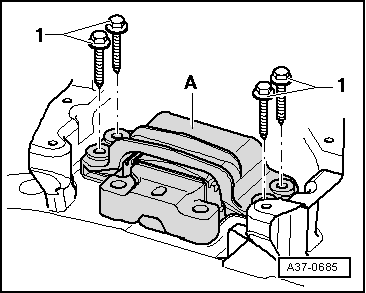

Caution | The threads in the gearbox support can be damaged if the bolts are not inserted straight. |

| t

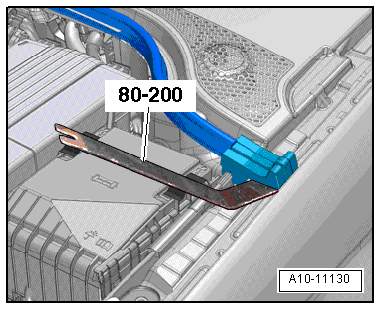

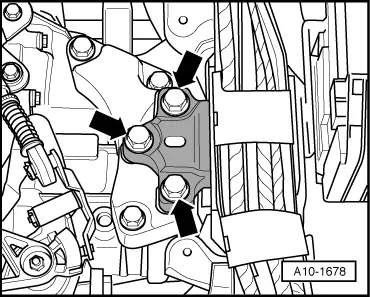

| Before fitting the bolts -arrows-, the gearbox support and the support arm of the gearbox mounting must be aligned absolutely parallel. If necessary, push the gearbox up at the rear with a trolley jack. |

| t

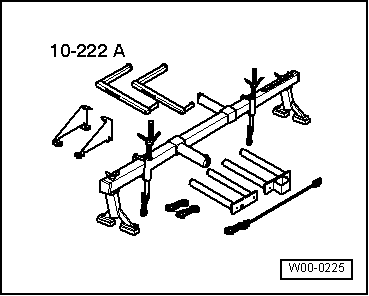

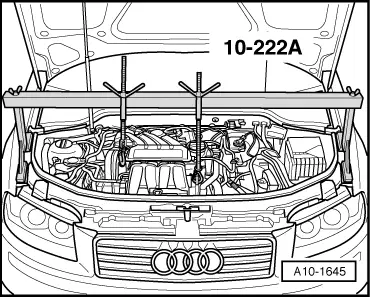

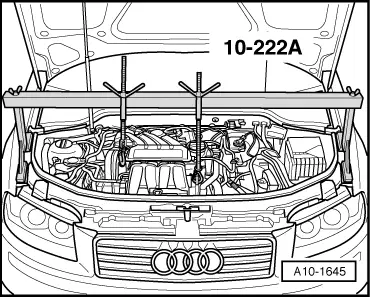

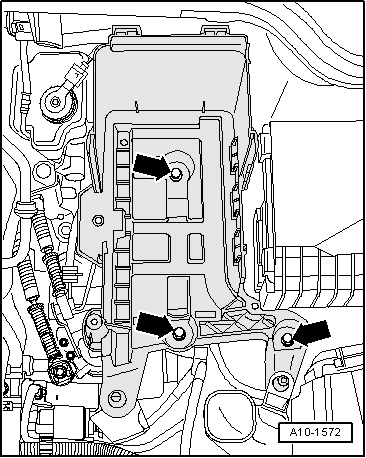

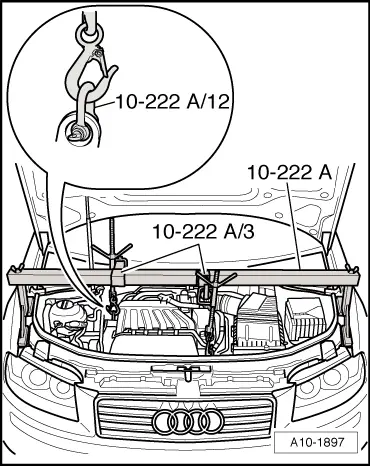

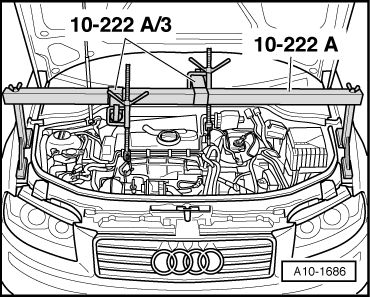

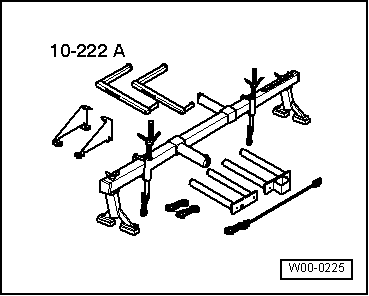

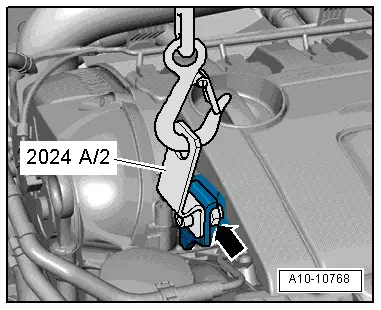

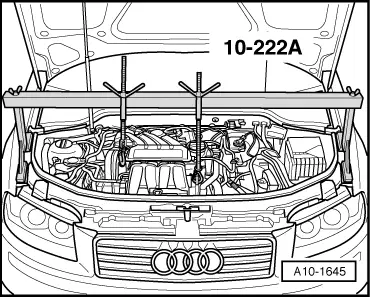

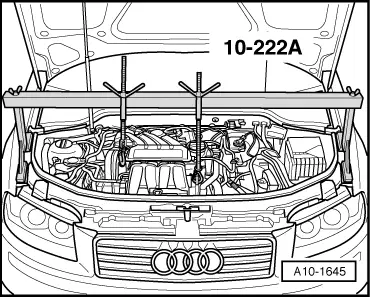

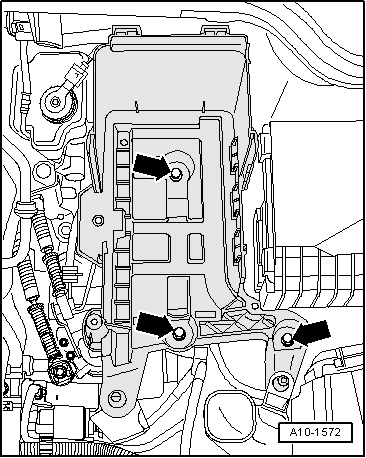

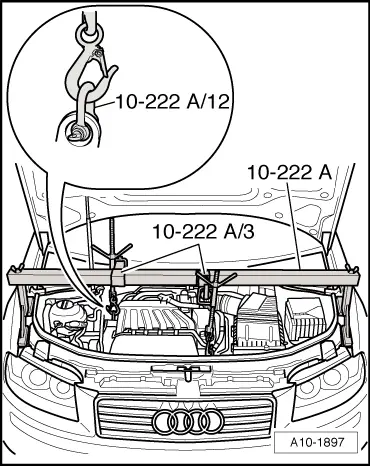

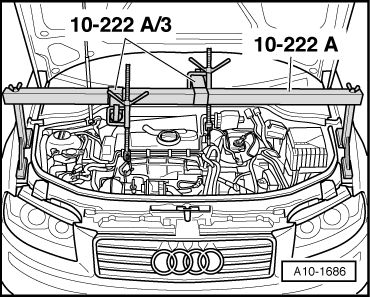

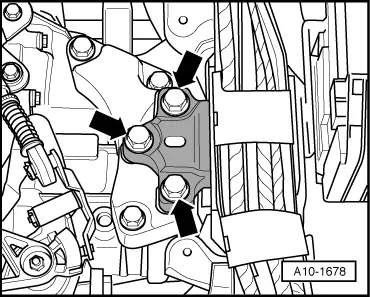

| Do not remove support bracket -10 - 222 A- until all bolts -arrows- securing the engine/gearbox mountings have been tightened to the specified torque. |

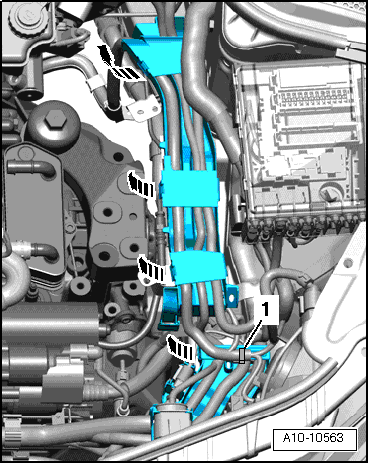

|