Freelander Service Procedures

AUTOMATIC GEARBOX - JATCO

44-26

REPAIRS

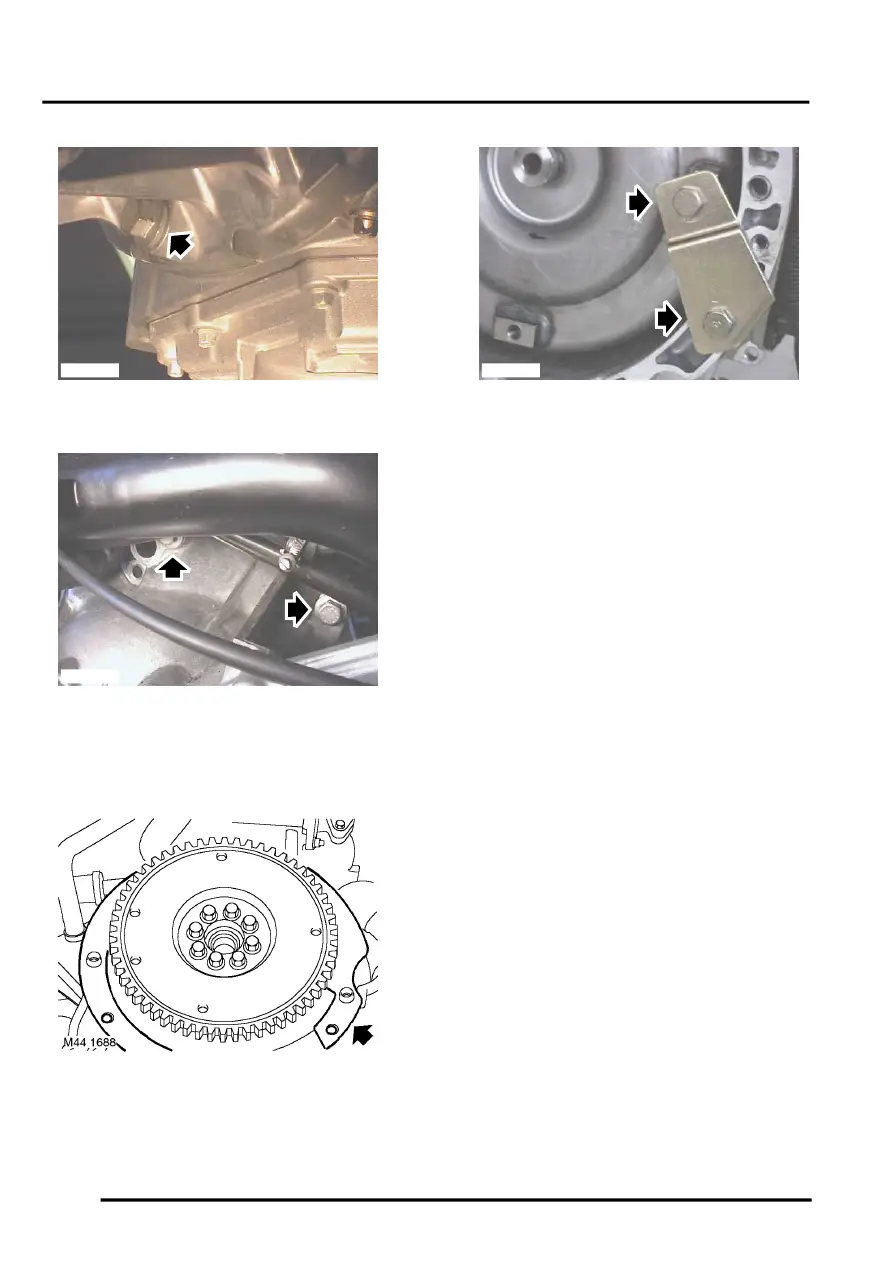

26. Remove lower bolt securing gearbox.

27. Remove 2 upper bolts securing gearbox to

engine.

28. Release gearbox from 2 dowels.

29. Manoeuvre and lower gearbox to floor.

30. If necessary remove displaced gearbox closing

panel.

31. Fit converter retaining plate and secure with

bolts.

Refit

1. Clean gearbox closing panel.

2. Ensure closing plate is in position on engine

and located on dowels.

3. Clean drive plate and ensure free from cracks

and distortion.

4. Clean gearbox to engine mating faces, dowels

and dowel holes.

5. Remove torque converter retaining plate.

6. Ensure torque converter is fully located in oil

pump drive by checking depth 'A' as illustrated.

Depth A = 27 mm.

7. Fit lifting chains to eyes and take weight of

gearbox.

8. Raise gearbox and engage with dowels. Fit

bolts securing gearbox to engine and tighten to

85 Nm (63 lbf.ft).

9. Fit bolt securing closing plate to gearbox and

tighten to 10 Nm (7.5 lbf.ft).

10. Remove lifting chains from gearbox.

11. Fit mounting bracket to gearbox and tighten

bolts to 85 Nm (63 lbf.ft).

12. Raise engine, align bracket to mounting and

tighten through bolt to 100 Nm (74 lbf.ft).

13. Remove engine support chains.

14. Align torque converter to drive plate and tighten

bolts to 45 Nm (33 lbf.ft).

15. Fit grommet to access plate.

16. Fit trunnion to selector lever, fit inner cable to

trunnion and secure outer cable to abutment

bracket.

17. Adjust selector cable.

ADJUSTMENTS, Selector cable - adjust.

18. Connect gearbox harness multiplugs and fit to

clips.

19. Position earth lead to gearbox and tighten bolt

to 25 Nm (18 lbf.ft).

20. Connect intercooler hose and tighten clip.

M44 1687

M44 1686

M44 1689