Freelander Service Procedures

ENGINE - K SERIES KV6

12-3-96 OVERHAUL

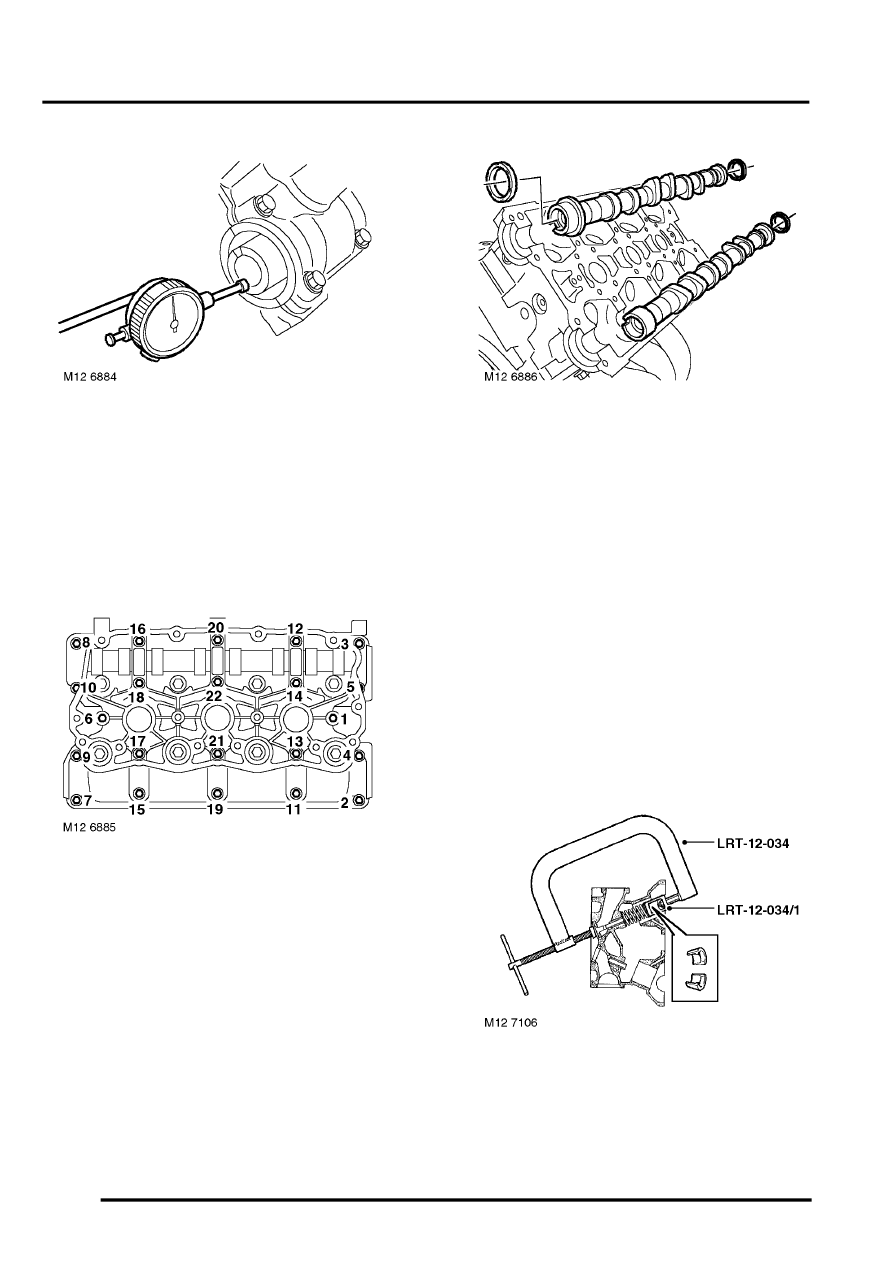

12. Check end-float of camshafts using a DTI.

CAUTION: If camshaft end-float exceeds

limits given, repeat check with new

camshaft(s). If end-float is still excessive,

replace cylinder head and camshaft carrier

as an assembly.

13. Using sequence shown, progressively loosen

22 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released

and remove bolts.

14. Remove camshaft carrier.

15. Remove camshafts and discard oil seals.

Note: Inlet camshafts are colour coded orange,

exhaust camshafts

16. Using a stick magnet, remove 12 hydraulic

tappets from cylinder head.

CAUTION: Store hydraulic tappets in their

fitted order and store upright. Maintain

absolute cleanliness when handling

hydraulic tappets. Failure to observe these

precautions can result in engine failure.

17. Measure the outside diameter of hydraulic

Note: Measurement must be taken half-way

along tappet body.

18. Using LRT-12-034, and adapter LRT-12-034/1,

compress valve spring, remove 2 collets,

release valve spring and remove LRT-12-034.

19. Remove valve spring cap and valve spring.

20. Remove valve from cylinder head.