Freelander Service Procedures

ENGINE - K SERIES KV6

12-3-78 OVERHAUL

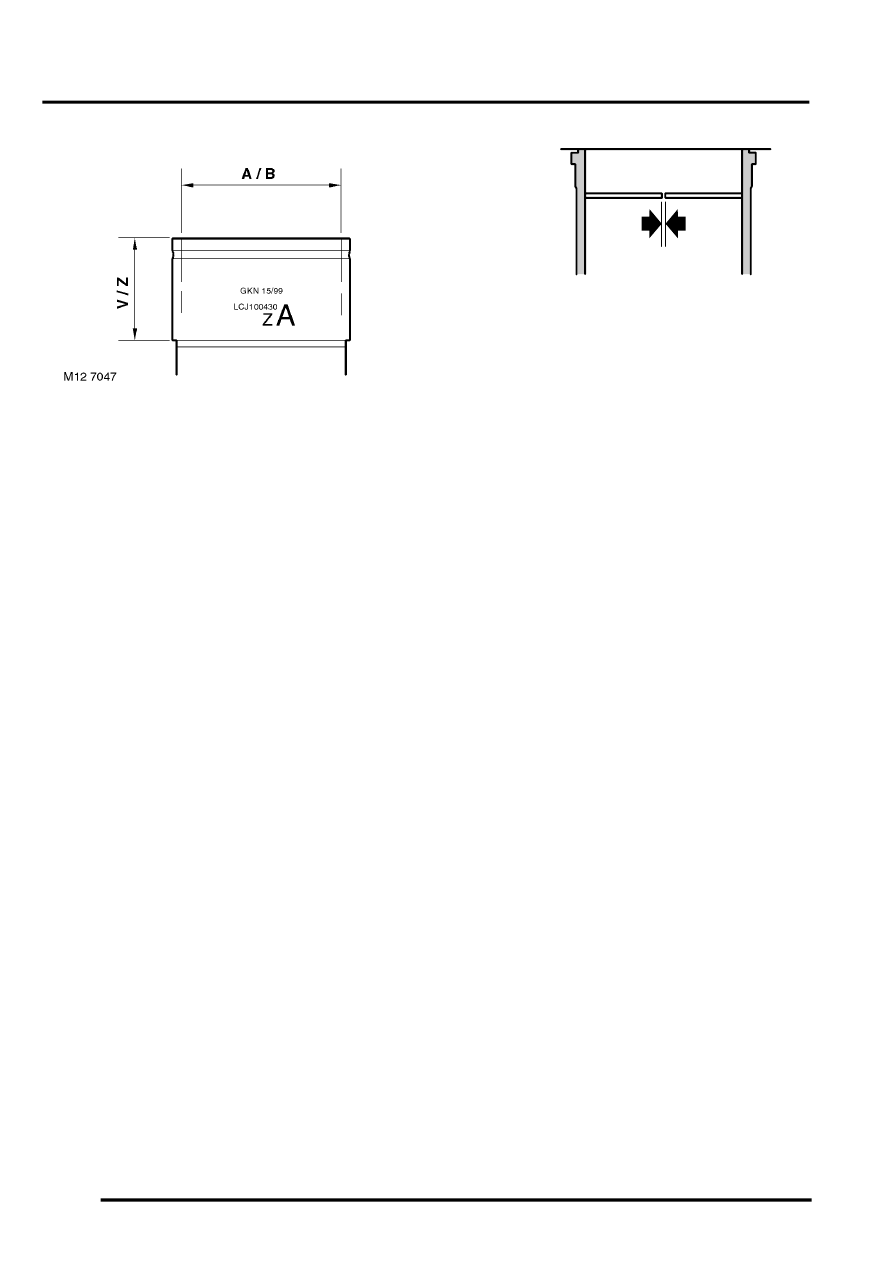

2. Cylinder liners have their bore/grade and step

height determined at manufacture. The bore/

grade, red, blue (A) or (B), and step heights V

or Z together with the cylinder liner part number

and colour code are marked on the external

diameter of the cylinder liners. If cylinder(s) are

to be replaced, the replacement liner(s) must

have the same step height as the original

liner(s). Both step heights are available in red

(A) and blue (B) grades of cylinder liners.

3. Check pistons for distortion and cracks.

NOTE: Piston grades A or B are stamped on

the crown of the piston.

4. Piston diameter check: Measure piston

diameter at right angles to gudgeon pin and 8

mm (0.3 in) from bottom of skirt.

NOTE: Piston and connecting rods are only

supplied as an assembly.

CAUTION: Ensure pistons are retained with

their respective cylinder liners.

5. Position piston in cylinder liner and measure

clearance 20 mm (0.75 in) from bottom of

cylinder liner.

6. Piston ring gap: Position new top and second

compression piston rings 20 mm (0.75 in) from

top of cylinder bore and measure ring gaps.

CAUTION: Ensure piston rings are kept

square to liner bore. Retain rings with the

piston fitted to the liner in which they were

checked.

7. Piston rings - refit:Using a suitable expander,

fit oil control spring.

8. With 'TOP' or identification markings to top of

piston, use an expander to fit piston rings in

sequence; oil control, 2nd and top

compression.

NOTE: The second compression ring is

stepped.

M12 6838