Freelander Service Procedures

ENGINE - K SERIES KV6

OVERHAUL 12-3-79

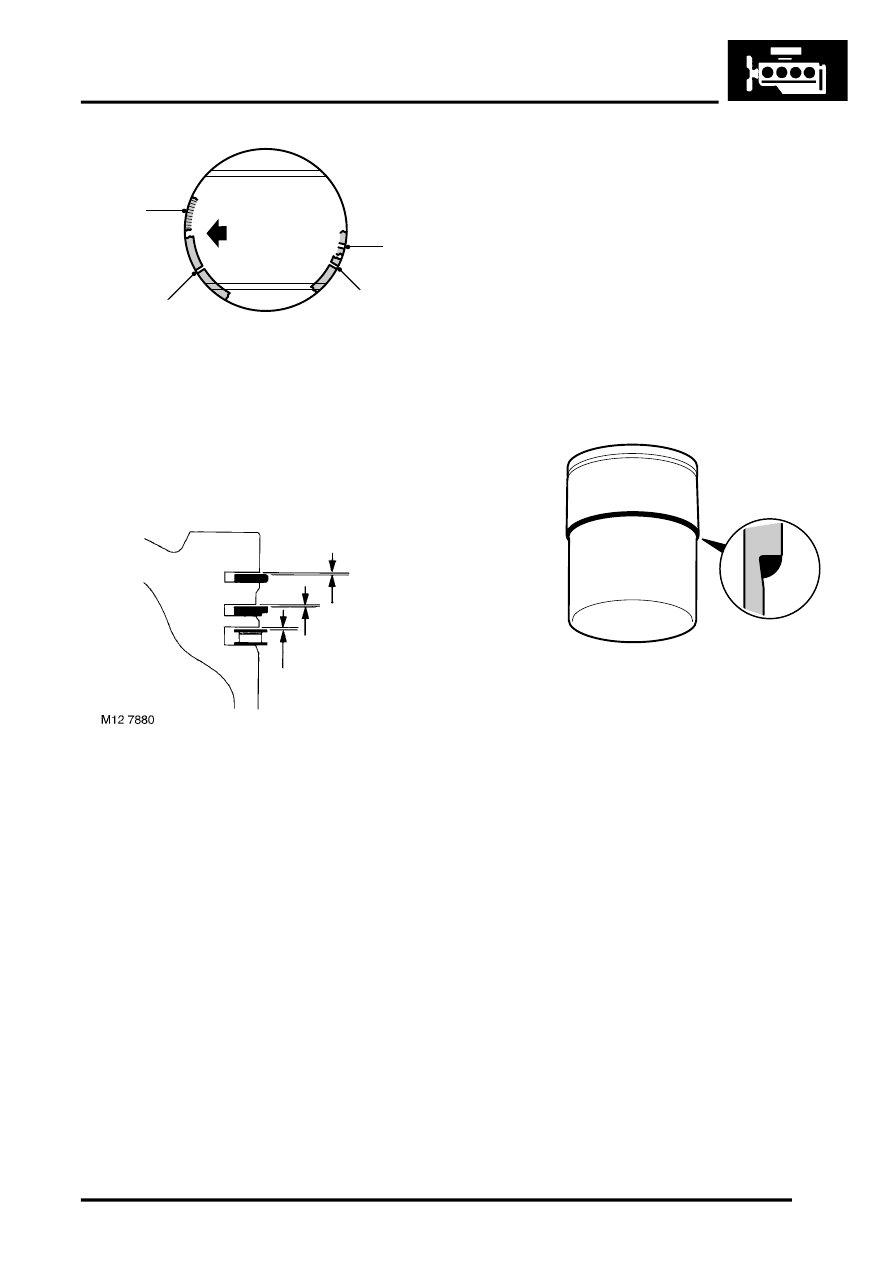

9. Ensure rings are free to rotate, position

compression ring gaps A and B at 120

°

to each

other and away from thrust side. Position oil

control ring gap C and spring gap D at 30

°

on

opposite side of gudgeon pin axis.

10. Check clearance of each piston ring to its

respective groove.

Reassembly

1. Clean cylinder liners and liner recess in cylinder

block.

2. Lubricate cylinder liner bores, pistons and rings

with clean engine oil, ensure ring gaps are

correctly spaced.

3. Clean bearing shell recesses in connecting

rods and bearing caps.

4. Fit piston ring clamp, LRT-12-204 to each

piston in turn and fit piston to its respective

cylinder liner ensuring that when fitted, arrow

on piston crown will be towards front of engine.

CAUTION: Do not push pistons fully down

bores at this stage.

5. Remove piston ring clamp.

6. Apply a 2.00 mm (0.1 in) thick continuous bead

of sealant, Part No. RTC 3347, around

shoulder of each cylinder liner as shown.

7. Keeping cylinder liner 'square' to cylinder block,

push each liner fully down until shoulder of liner

seats against cylinder block ensuring that the

arrow on the piston is towards front of engine.

8. To prevent cylinder liners from being displaced,

position LRT-12-144 cylinder liner clamps and

secure to cylinder block with cylinder head

bolts. Ensure that feet of clamps do not

protrude over liner bores.

9. Fit crankshaft.

M12 6839

D

B

A

C

M12 6842