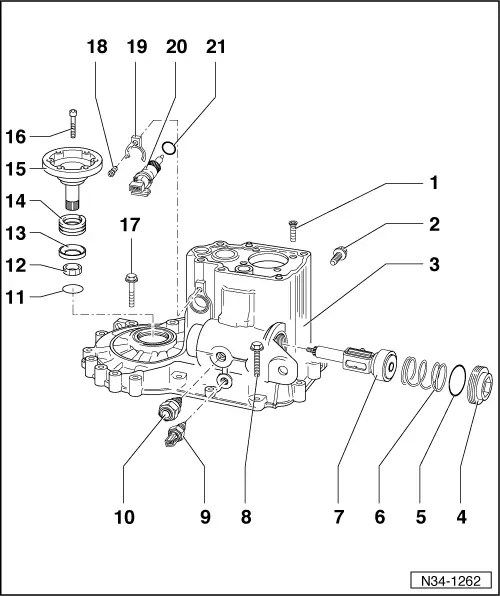

Leon Mk1

| Gearbox casing and gearbox selector shaft: removing and installing |

| 1 - | Screw M 7 X 23 |

| q | 15 Nm |

| q | 4 units |

| q | To fit the ball bearing retaining plate to the gearbox housing |

| 2 - | Bolt |

| q | 20 Nm |

| q | For the reverse gear/shaft |

| 3 - | Gearbox casing |

| q | Repairing → Chapter |

| 4 - | Sealing cap |

| q | 50 Nm |

| 5 - | O-ring |

| q | Renew (if fitted) |

| 6 - | Compression spring |

| q | Maintains the selector shaft and the gear stick compressed in the 3rd and 4th gear tracks |

| 7 - | Gear selector shaft |

| q | Repairing → Chapter |

| 8 - | Screw M 8 x 35 |

| q | 25 Nm |

| q | 2 units |

| q | Fit below the reversing light switch → Item |

| 9 - | Reversing light switch |

| q | 20 Nm |

| 10 - | Bolt |

| q | 40 Nm |

| 11 - | Safety ring |

| q | Maintains the conical ring, thrust washer and the compression spring in their position when the flanged shaft is removed |

| 12 - | Conical ring |

| q | With recess for the thrust washer |

| q | Assembly position: conical side facing the differential casing |

| 13 - | Thrust washer |

| q | Assembly position: collar towards the spring, core towards the conical ring |

| 14 - | Compression spring |

| 15 - | Articulation flange |

| q | Dismantling and fitting → Chapter, Articulation flange oilseals: removing and installing |

| 16 - | Bolt |

| q | 25 Nm |

| 17 - | Screw M 8 x 52 |

| q | 25 Nm |

| q | 12 units |

| 18 - | Bolt |

| q | 5 Nm |

| 19 - | Support |

| 20 - | Speedometer control |

| 21 - | O-ring |

| q | Always renew |