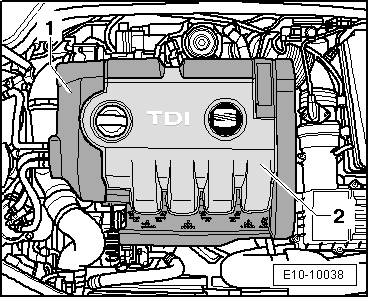

Leon Mk1

|

| Special tools and workshop equipment required |

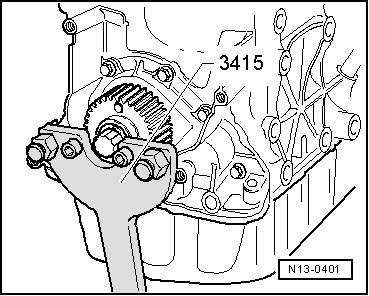

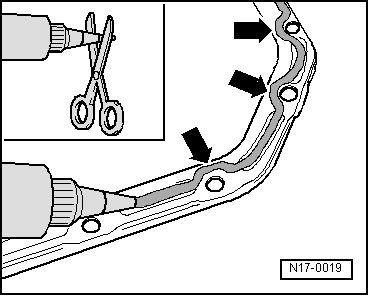

| t | Hose clamp -3415-, see equivalent → Anchor |

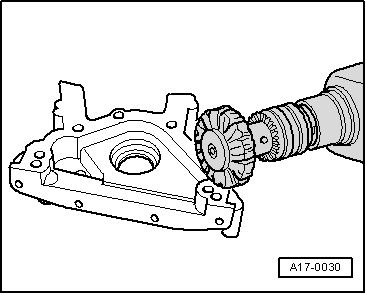

| t | Guide sleeve -T10053-, see equivalent → Anchor |

| t | Tightening torque -VAG 1331-, see equivalent → Anchor |

| t | Tightening torque -VAG 1332-, see equivalent → Anchor |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

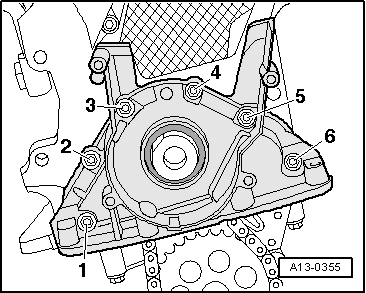

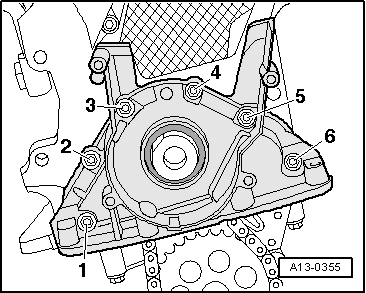

| Component | Nm | |

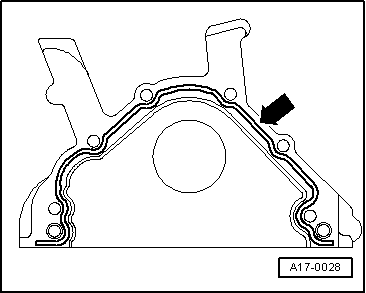

| Sealing flange to cylinder block | 15 | |

| Crankshaft toothed belt wheel | 120 + 90° 1)2) | |

|

WARNING

WARNING