| –

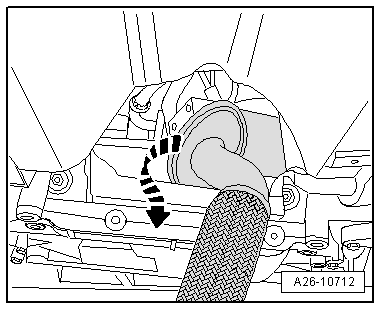

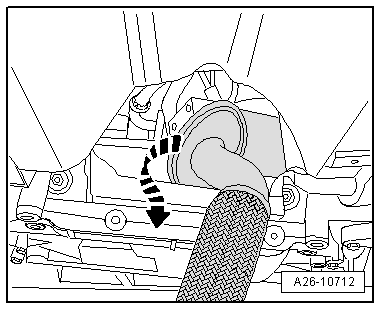

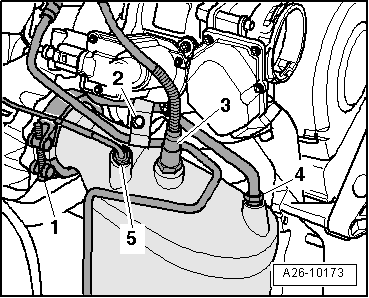

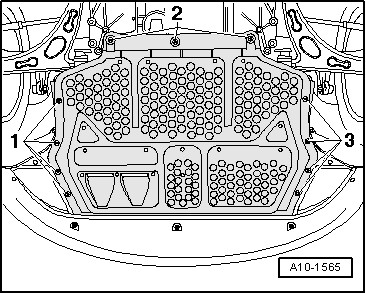

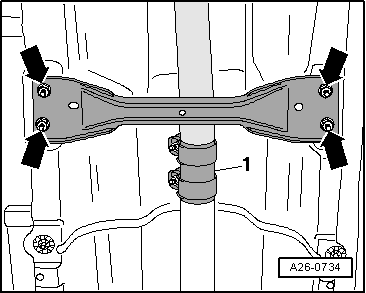

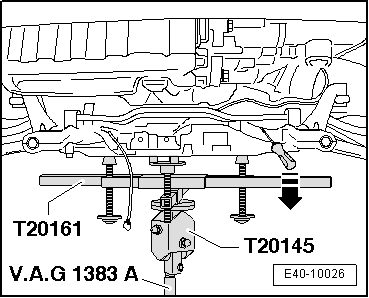

| Remove the particle filter by turning it by 180° clockwise. In doing so, slightly press the engine / gear unit to the front and remove the filter between the tunnel and the mechanical bridge support unit. |

| Continue the installation in the reverse order of removal sequence, observing the following: |

Note | t

| When replacing the particle filter, the transport protection on the coupling element should not be removed until just before fitting. |

| t

| Fit the cable clamps in the same position as they were. |

| t

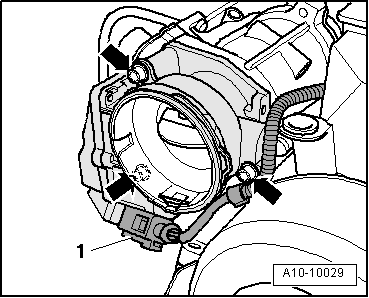

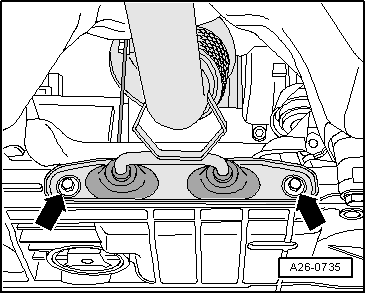

| Ensure that the clamp for the particulate filter is fitted correctly → Anchor |

| t

| Replace seals, gaskets and self-locking nuts. |

| t

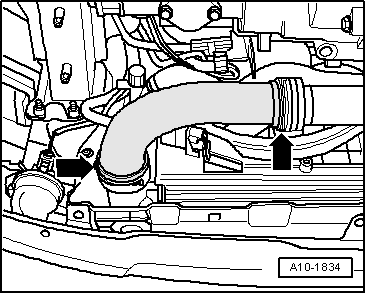

| The sleeves for the hoses and the supercharger air flow tubes should be free of oil and grease before fitting. |

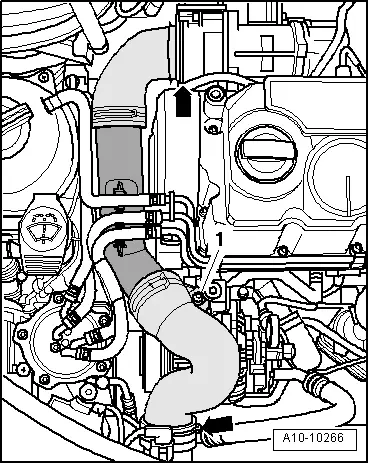

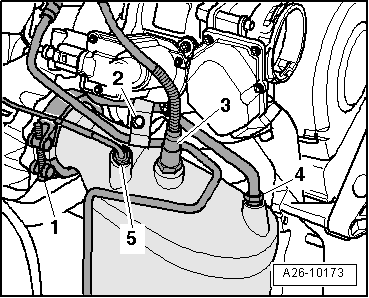

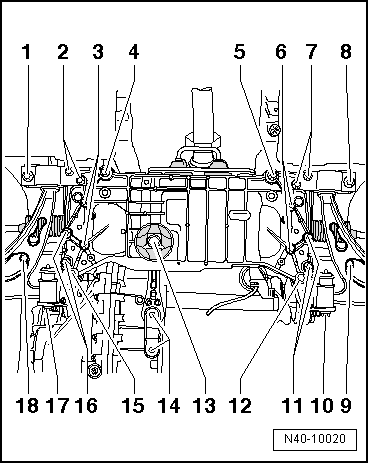

| In order to correctly fit the clamp, pressure pipes and particle filter brackets, approach the elements without tightening: |

| t

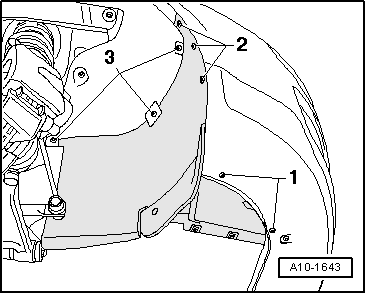

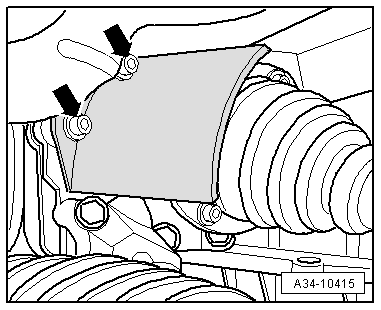

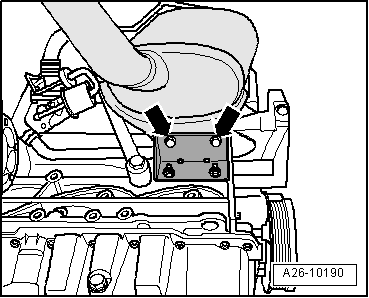

| Fit the gasket and the double clamp for the particle filter to the turbocharger. |

| t

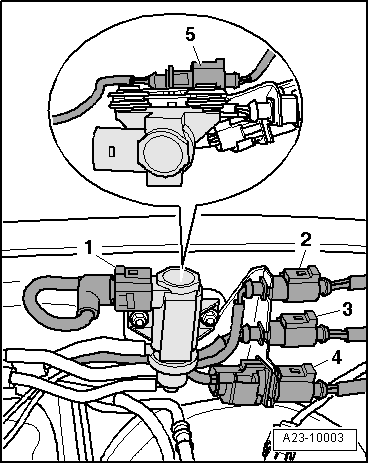

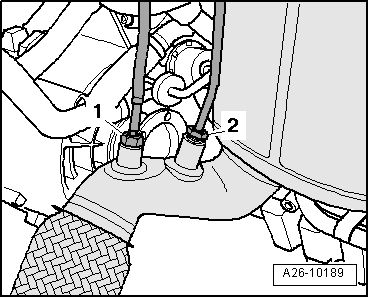

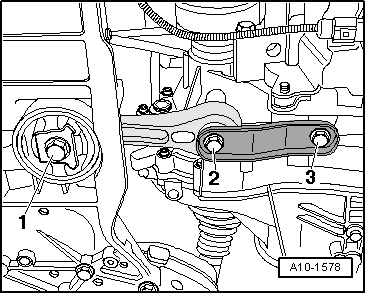

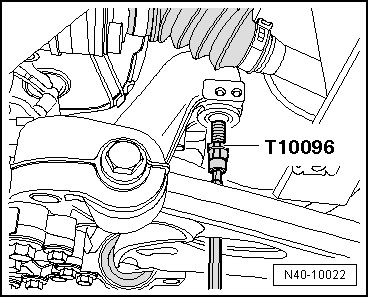

| Manually screw in the injector pipe connections to the particle filter → Item. |

| t

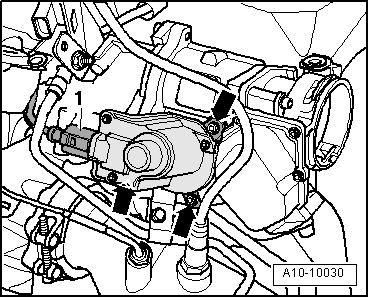

| Fit the injector pipe bracket to the particle filter → Item. |

| t

| Screw the bracket bolts to the particle filter in by hand → Item. |

| Tightening torque sequence for the particle filter elements: |

| t

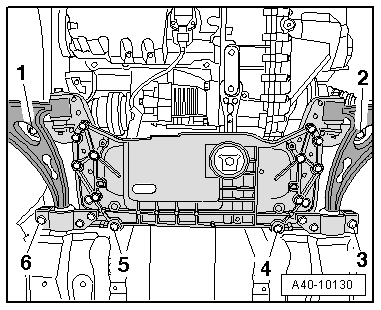

| Bracket on the particulate filter → Item |

| t

| Bracket of the pressure lines on the particulate filter → Item |

| –

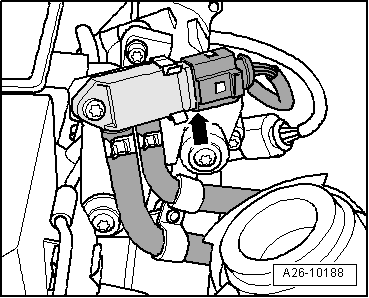

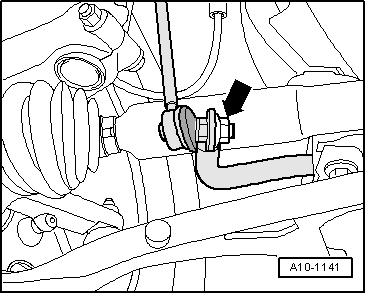

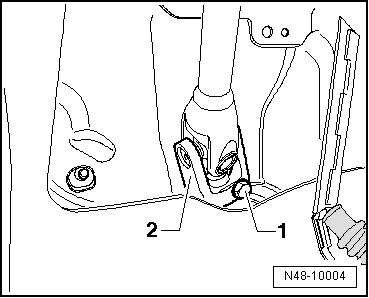

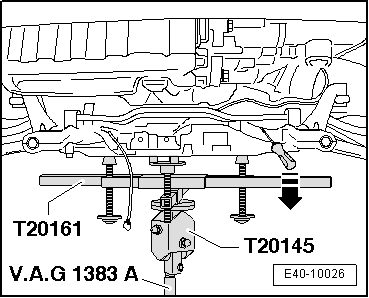

| Remove the exhaust gas temperature sender 2, bedplate 1 -G448- → Item. |

| –

| Install the temperature sender after the particulate filter -G527- → Item. |

| –

| Fit the bracket of the exhaust gas pressure sensor 1 -G450- on the cylinder head cap → Item. |

| –

| Align exhaust system without tension → Chapter |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note