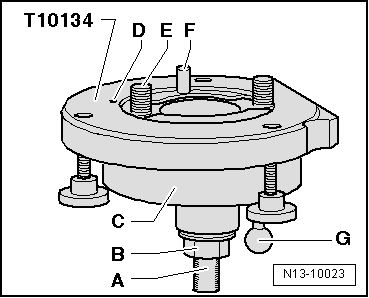

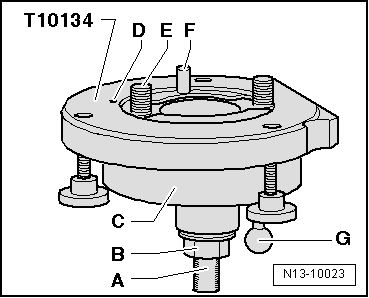

| To fit the sealing flange with the sender wheel to the crankshaft |

Note | t

| The sealing flange with the PTFE seal is fitted with a pressure ring on the sealing lip. This pressure ring fulfils the function of an assembly sleeve and cannot be removed before fitting. |

| t

| Once unwrapped, do not separate the sealing flange and the sender wheel or modify the position. |

| t

| The sender wheel finds its position automatically when fitted to the position pin of the assembly device -T10134-. |

| t

| The sealing flange and the seal make up one inseparable component and can only be replaced along with the sender wheel. |

| t

| The position of the centre guide -T10134- with respect to the crankshaft is determined by a guide pin inserted in a threaded space in the crankshaft. |

|

|

|

Note

Note

Note

Note