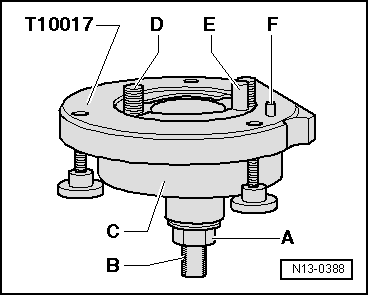

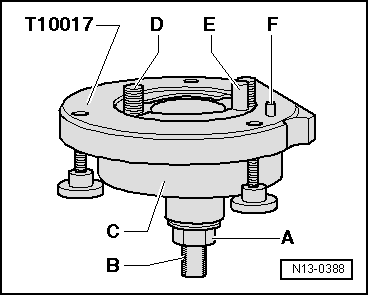

| Insert pressing the sealing flange with the sender wheel onto the crankshaft |

Note | t

| Progressive use of a new generation of sealing flanges with PTFE seal (Teflon). The sealing flange with elastic washer continues to be available as a spare part. |

| t

| When fitting a new sealing flange, only use the same type of flange as previously fitted. |

| t

| The sealing flange with the PTFE seal is designed with a pressure ring on the sealing lip. This pressure ring fulfils the function of an assembly sleeve and cannot be removed before fitting. |

| t

| Once assembled, do not separated the sealing flange and the sender wheel or modify the position. |

| t

| The seal surface of the sealing flange with elastic washer of the sender wheel with respect to the crankshaft has an elastomeric layer. This layer should always be kept free of dirt and grease. |

| t

| The sender wheel finds its position automatically when fitted to the position pin of the centre guide -T10017-. |

| t

| The sealing flange and the seal make up one inseparable component and can only be replaced along with the sender wheel. |

|

|

|

Note

Note

Note

Note