| t

| Torque wrench -V.A.G 1331- |

Caution | If the turbocharger has suffered mechanical damage (e.g. damaged compressor wheel), it is not sufficient merely to fit a new turbocharger. |

| To prevent this from causing further damage, perform the following repairs: |

| t

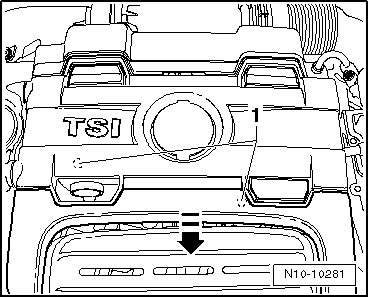

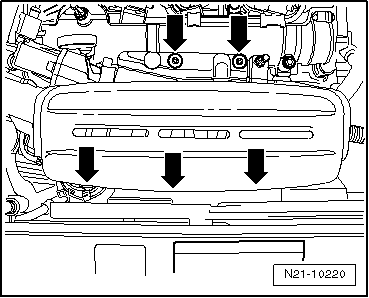

| Check air filter housing, air filter element and intake hoses for soiling. |

| t

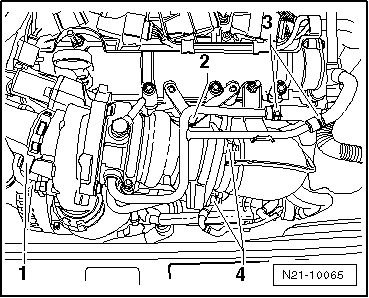

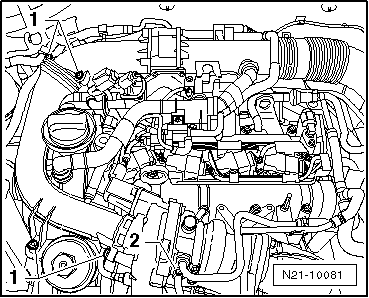

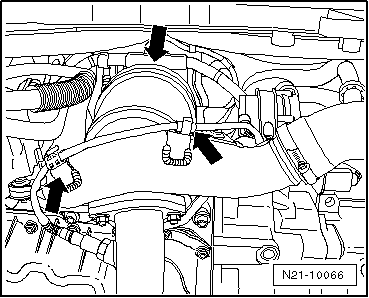

| Check complete charged air routing and charge air cooler for foreign objects. |

| If foreign matter is found in the charge air system, clean all relevant ducts and hoses and renew the charge air cooler if necessary. |

|

Note | Before carrying out further work, disconnect battery earth strap. Check whether a coded radio is fitted. Obtain anti-theft coding if necessary. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution