| Disassembling and assembling differential gear |

| Special tools and workshop equipment required |

| t

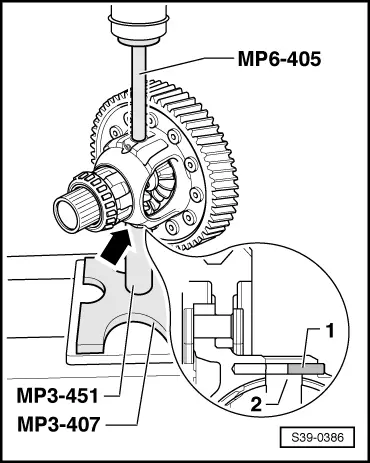

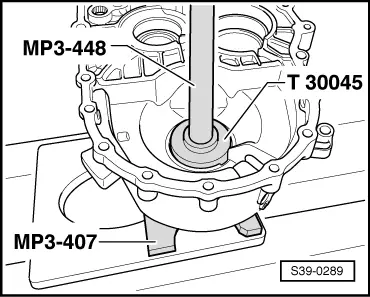

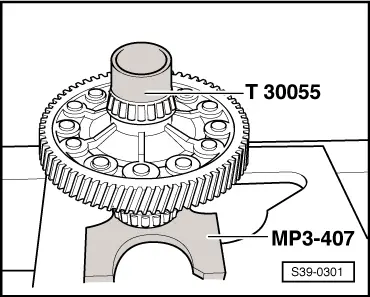

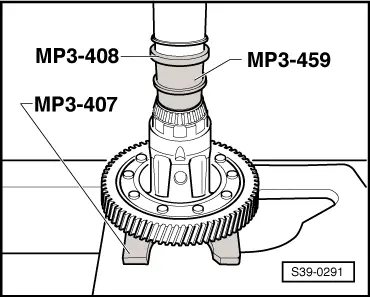

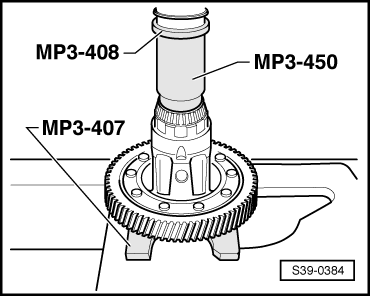

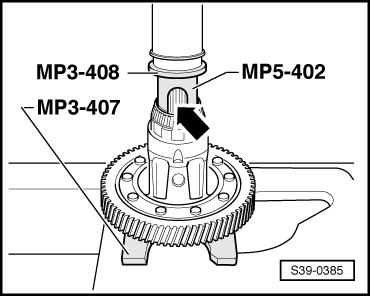

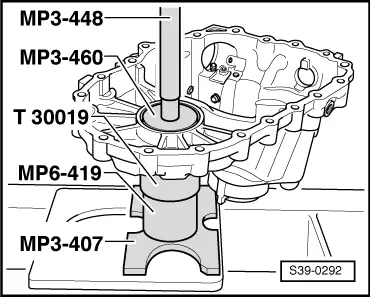

| Pressure plate -MP3-407 (VW 402)- |

| t

| Pressure spindle -MP3-408 (VW 412)- |

| t

| Pressure spindle -MP3-448 (VW 408A)- |

| t

| Pipe section -MP3-450 (VW 415A)- |

| t

| Pipe section -MP3-451 (VW 422)- |

| t

| Thrust piece -MP3-459 (VW 473)- |

| t

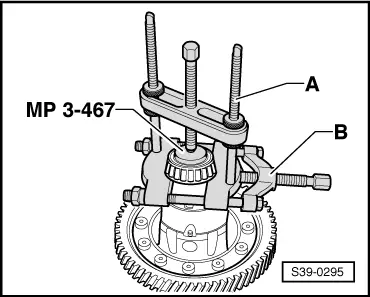

| Pressure washer -MP3-467 (40-105)- |

| t

| Assembly device -MP5-402 (3301)- |

| t

| Pressure spindle -MP6-405 (VW 411)- |

| t

| Thrust plate -T30045 (3005)- |

| t

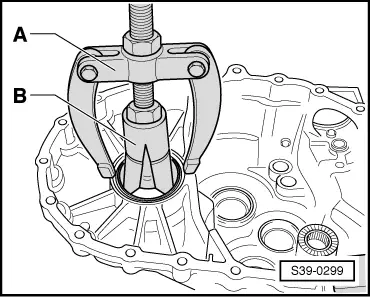

| Separating device 12...75 mm, e.g. - Kukko 17/1- |

| t

| Extractor, e.g. -Kukko 18/1- |

| t

| Interior extractor 46 up to 58 mm, e.g. -Kukko 21/7- |

| t

| Countersupport e.g. -Kukko 22/2- |

| t

| Extractor, e.g. -Kukko 204/2- |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note