Octavia Mk2

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

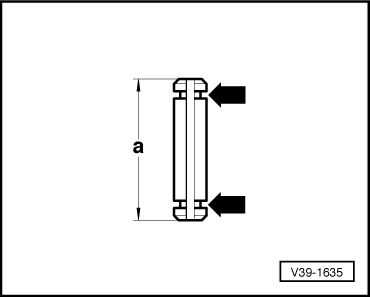

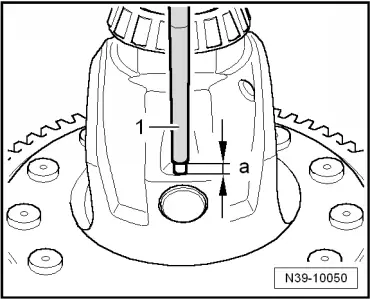

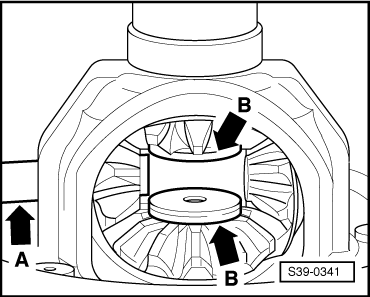

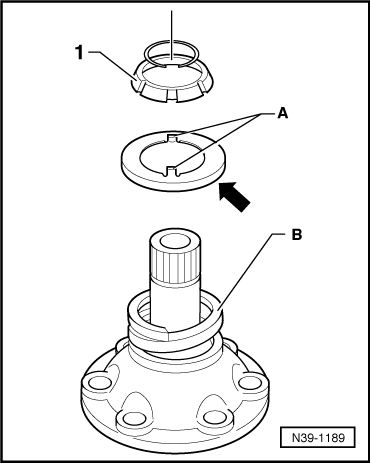

| Dimension „a“ mm | Distinguishing feature | |

| 28.5 (short tensioning sleeve) | with round slot -arrows- | |

| removing and installing → Fig. | ||

| 36.0 (long tensioning sleeve) | without round slot | |

| removing → Fig. | ||

| installing → Fig. | ||

|

|

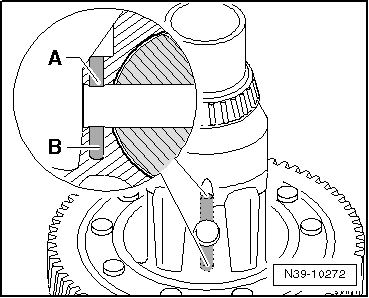

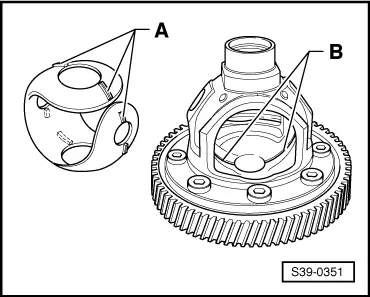

| Bore | Length of tensioning sleeve (mm) | |

| »A« | 28.5 (short tensioning sleeve) | |

| »A« and »B« | 36.0 (long tensioning sleeve) | |

|

|

|

|

|

|

|

|

|

|

|

|