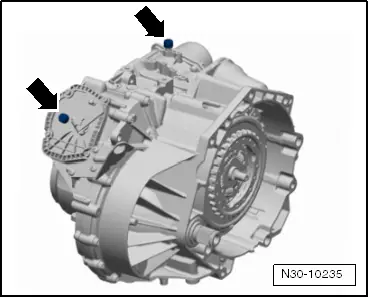

| Install the double clutch „new design“ as of 06.11 |

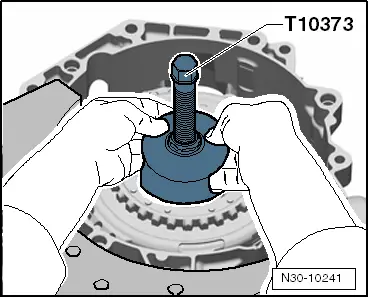

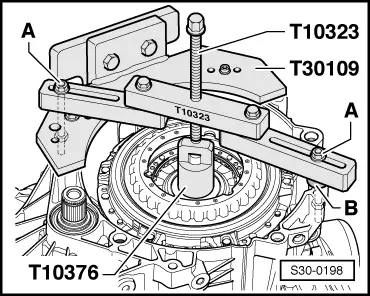

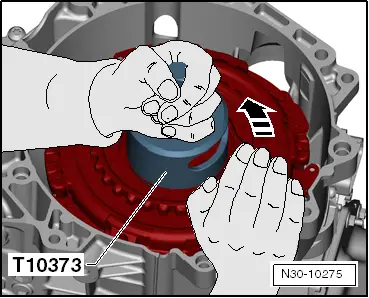

| Special tools and workshop equipment required |

| t

| Supporting bridge -T10323- |

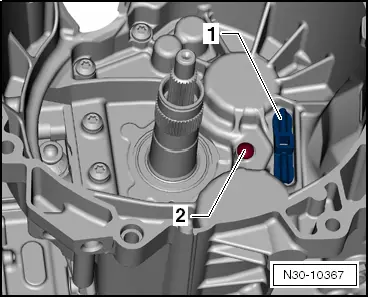

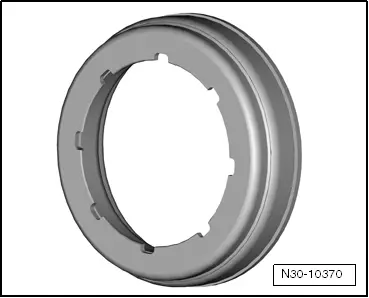

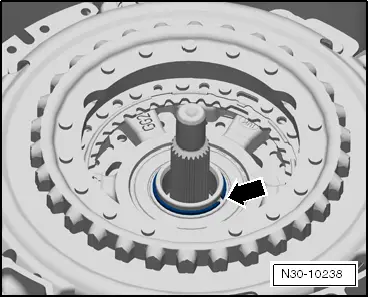

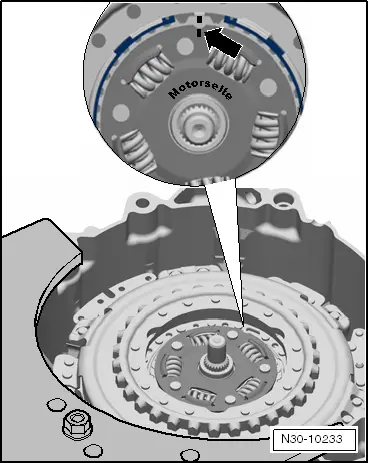

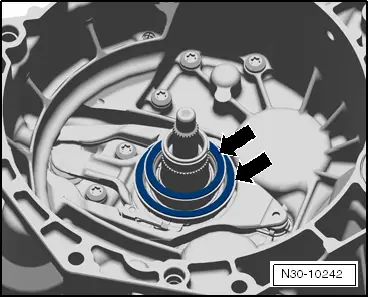

Note | The large adjusting washer for the clutch „K1“ is inserted with the semispherical side downwards on the large bearing, the small adjusting washer for the clutch „K2“ is inserted under the small bearing. |

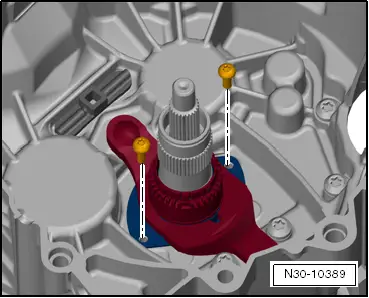

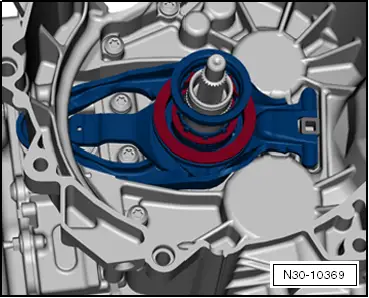

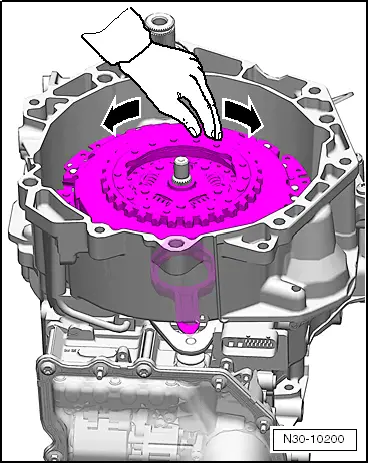

| Before installing the clutch, the position of the engaging bearings „K 1 and K 2“ must be adjusted → Chapter. |

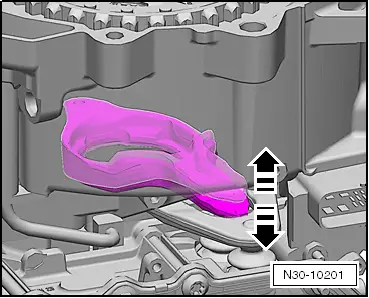

| The position of the engaging lever must be adjusted if: |

| t

| The clutch was replaced |

| t

| The engaging levers were replaced |

| t

| The ball stud for „K2“ was replaced |

| t

| The engaging bearing was replaced. |

| If all the mentioned parts are only removed and reinstalled, there is nothing to adjust. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution